Not every packaging operation runs at high speed with top-of-the-line systems that have all the bells and whistles. Lower and medium-volume production lines need affordable products that provide the necessary level of automation. Here are four new products that do just that, and will be on display this week at PhillyPack (Oct. 7-8; Philadelphia).

Our first new product is the Zanasi Z4700 small-character inkjet coder (photo above) with easy-to-use Orkestra software that can customize the user interface for a single operator. The system—which can be integrated or connected through Ethernet, USB and serial ports—prints up to four lines of text, bar codes or images at speeds up to 1,320 feet per minute on primary and secondary packages using a variety of inks, including soy-based ink.

I.D. Systems Inc., PhillyPack 2015 Booth 1833

Next: A wide-belt conveyor with washdown capabilities

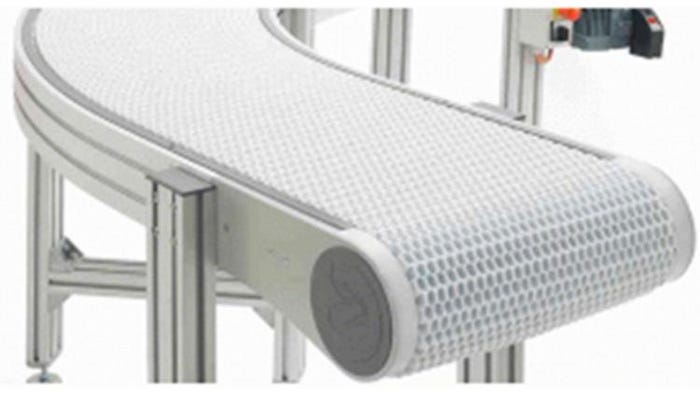

The new WLX wide-belt conveyor features a hygienic design and allows for complete washdown. The conveyor is suitable for any production line, but it is especially appropriate for food-packaging operations that require high cleanliness, from meat to bakery products.

FlexLink Systems Inc., PhillyPack 2015 Booth 1624

Next: A hot-melt sealer with digital temp controls

This new pre-assembled Benchmark 205-LV4 hot melt system comes ready to run. Designed for low- and medium-volume operations, it is easy to operate and maintain. It’s also affordably priced yet features accurate digital temperature controls. The tank holds approximately 8 lbs of hot melt, which is about 45 minutes of run time since the system processes about 10 lbs of adhesive per hour.

Hot Melt Technologies, PhillyPack 2015 Booth 1826

Next: A low-volume filler

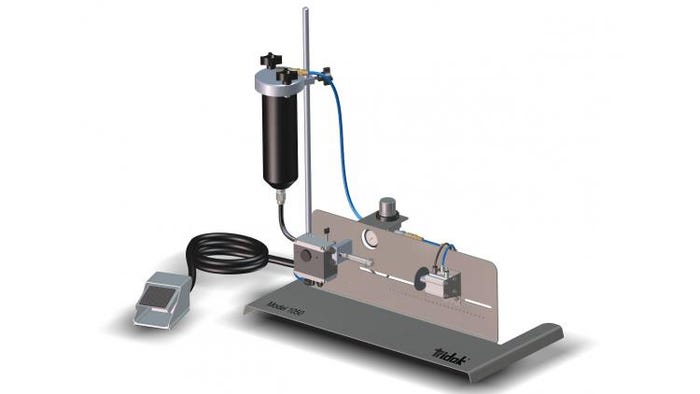

The Tridak Model 1050 fills single syringes from a material reservoir. The unit’s manual loading and unloading makes it suitable for low-volume production or manual filling operations that are ready to upgrade and boost production. The filler uses a Model 830 disposable fluid path valve for fast and easy material changeovers while also minimizing cross-contamination of products. The valve also features adjustable suck-back for accurate, clean cut-off of stringy or tacky materials.

Dymax Corp., PhillyPack 2015 Booth 1919

About the Author(s)

You May Also Like