February 3, 2015

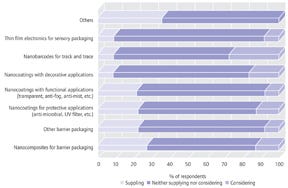

Packaging applications targeted with nanotechnology by suppliers. Click here to view the chart at a larger size. Source: Pira Intl.

The key to designing a good brand-protection technology is to make it easy for brand owners and their investigators to identify genuine goods, while making it very difficult for counterfeiters and crooks to know how that is being done. Nanotechnology can provide such a solution. Using nanotechnology, companies can now apply covert information, such as batch information, directly onto products and packaging. They can, for example, encrypt nanoscale codes onto pharmaceutical pills for tracking and tracing. They can also create nano bar codes, which are invisible bar codes that are technologically complex but can be used to easily authenticate products and packaging. Many more significant advances in nanotechnology are on the way, and the possibilities are almost endless.

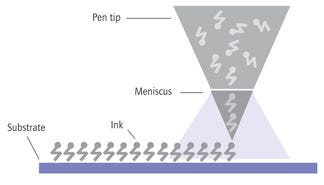

NanoInk uses a scanning probe—a molecule-coated probe tip that acts like a pen—to deposit material onto a surface.

There are two main reasons to use authentication and track-and-trace features on a product: to fight counterfeiting and to prevent the diversion of products destined for a particular market. Brand owners have learned that in order to fight counterfeiting, security technology is often needed. The best solution is to use a combination of overt and covert features, or features that are and are not visible to the naked eye, respectively.

Overt features, such as holograms, are useful because they can enhance a product's image, and consumers recognize them as marks of authenticity. Holograms, however, are susceptible to counterfeiting because the technology is widely available.

Covert features are useful in the fight against counterfeiting because, under normal circumstances, counterfeiters will not even know they exist. If they do discover the existence of covert marks, they will be deterred from attempting to copy them for the straightforward reason that invisible marks are difficult to imitate. In addition, covert features are useful in the fight against unauthorized diversion. With information hidden on its products, a brand owner can keep track of where distributors are sending its goods.

For example, if a batch number is tied in with a destination and is hidden on the product's package, a brand owner's authorized investigator will know when the company's products show up in a market where they are not supposed to be. The investigator can trace where products were originally sent and find the distributor that allowed the diversion.

This system has the potential to allow brand owners to monitor their supply chains without having to share company information with a variety of arms-length distributors and wholesalers. This is because only authorized people in the supply chain will have access to the information on the products.

Nanotechnology is the science of everything small. Everything done at the nanoscale is invisible to the naked eye, making nanotechnology the obvious choice for adding covert information to branded products. In order to protect public safety, regulatory agencies and governments are demanding that supply chains are as secure as possible.

Pharmaceutical companies are among the most heavily regulated groups and will be among the first to be forced to ensure their drugs are safe. Already in some places, such as in certain U.S. states, regulators are asking pharmaceutical firms to provide a drug pedigree—a drug's history from its point of manufacture—with the drugs they supply. Since pharmaceutical companies often employ cutting-edge nanotechnology in their drug research, they might be among the first to use it to provide this drug pedigree.

Owners of high-end brands are also likely to want to use high-security features incorporating nanotechnology. Because of the higher value of their products, they'll be willing to spend more if it will mean their products are better protected.

However, much of the technology is still confined to the laboratory. Many applications of nanotechnology have not been tested yet, and printing and packaging companies are still hesitant to invest in the technology—they'd rather use a technology that most brand owners are more comfortable with. What's more, the cost of nanotechnology is still too high to justify its use in many cases. Still, the technology is developing too quickly to ignore.

So what are technology companies doing? One U.S. nanotechnology company, NanoInk, Inc. (www.nanoink.net), Skokie, IL, is using its patented Dip Pen Nanolithography(TM) (DPN) technique to apply drug information directly onto pharmaceutical pills, and it hopes to use the same technique on packaging. The company would like to partner with packaging companies in order to provide a layered solution for pharmaceutical customers.

This illustration shows the template-directed synthesis of nano bar-code particles. Source: Oxonica, Inc.

NanoInk's DPN is a patterning technique that can be used for encrypting pills. NanoInk uses a scanning probe—a molecule-coated probe tip that acts like a pen—to deposit material onto a surface. The general process involves a chemically engineered ink-and-substrate combination, and the comprehensive nanoscale positioning control allows for high-quality nanolithographic patterns.

The technology has been used to encrypt pharmaceuticals at the pill level, but at press time, it has not yet been used on packaging. Company CEO, Dr. Cedric Loiret-Bernal, says that NanoInk is in discussions with several packaging companies, but nothing has been finalized.

As Loiret-Bernal explains, NanoInk can encrypt each pill with place and day of manufacture, target market and expiration date. He notes that it would be an added advantage to have the same encryption on the pill's packaging so that it would be evident if the pills had been repackaged. He adds that the patterning technique is preferred over the use of a taggant in the pill because the European Medical Agency doesn't like taggants. "And you can't have a solution that works in one market [the U.S.] and doesn't work in another [Europe] to solve a global problem," he says.

The pills will not be able to be authenticated in the field. Instead, they will be sent to an auditing center set up by NanoInk. The company plans to set up six auditing centers around the world, capable of auditing 50 million pills annually.

Loiret-Bernal says he can't go into detail about NanoInk's proprietary auditing process, but he says that it's much simpler than the process used currently, which involves liquid chromatography—a time-consuming and costly process.

Researchers at the National Physical Laboratory (NPL [www.npl.co.uk]) in the U.K. have also developed a way to write valuable information about a product using nanotechnology. They are using electron-beam nanolithography to hide valuable information about products from counterfeiters and crooks.

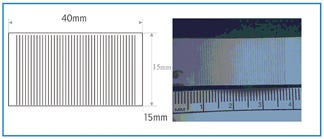

The actual size of a DataFiber tag. Source: ACS.

NPL researchers Dr. David Mendels and Dr. Alexandre Cuenat have discovered how to write tiny bar codes that can be applied to a product's surface in a coating, or simply embedded in a polymer layer. The researchers say they can fit the same amount of information as is contained in the King James Bible onto the sharp end of a pin. This means the technology has the potential to covertly store valuable information on product packaging, such as a drug pedigree, or authenticate high-value goods, such as diamonds.

Sian Brereton, a business development leader at NPL, says the laboratory hopes to exploit two key features of the technology. She says the technology carries information in a secure way because a special reader is needed for it to be decoded. In that way, it could be used to store information on passports and other forms of identification. Secondly, the information is so tiny that it cannot be seen with the naked eye, making it ideal for covert marking.

Brereton says the technology is close to commercialization, but NPL relies on partners to bring technology to the manufacturing stage. She notes that the laboratory is currently talking to a number of potential partners that could take the technology forward. "It's not something that needs considerable further development on the research side, but commercialization would depend on how quickly we come to an agreement and the investment required to tailor the technology to the application," she explains.

NPL researchers have discovered a way to write more than 90,000 nanoscale squares onto a particle of silicon 30 microns wide. The bar code, which takes the form of a cube, is coated with a 100-nanometer-thick layer of polymethyl methacrylate. The technology uses an electron-beam lithograph to drill 90,000 small squares into the plastic coat of each face at five different depths. The position and depth of each square is unique, so data can be encrypted using a key-based code. The cube is scanned line-by-line using an electron-force microscope, which detects differences in the depth of the squares. The information can then be verified by matching it with information created upon writing the code. According to the researchers, this scanning process takes less than a minute.

Once in mass production, NPL researchers estimate that each device will cost about $1.25, which means that the technology may not yet be suitable for consumer packaged goods due to its high cost. Another company using nanotechnology for authentication purposes is Oxonica, Inc., formerly Nanoplex Technologies (www.nanoplextech.com), in Mountain View, CA. The company is about to wrap up trials with several U.S.-based packaging companies that are using their nano bar codes for authentication and track-and-trace. The first application of the technology is likely to be on either packaging or labeling, and the company hopes to extend the technology so that it can eventually be used as a thread and put on materials.

Nanocomposite technology also paves the way for PACKAGING INNOVATION in the flexible film and plastic container industries. Read how at www.packagingdigest.com/info/nano05

Oxonica has finished developing the technology and has manufacturing processes in place. The product is supplied as a powder and can be added to liquid or surface coatings. The company has developed the nano bar-code particles to be used primarily as a covert tag for anti-counterfeiting applications. But the technology also has the ability to give each item or pallet, depending on how the company opts to apply it, a unique identity code allowing it to track where the product has been. Every item can be assigned a different code because the system allows for billions of unique codes.

The nanoparticles are made up of metals, including gold, silver and platinum, which create stripes using the different reflectivity of the metals. Oxonica can create different codes by altering the stripe order. The bar codes can only be read with a modified microscope and are likely to be used as a last-level taggant, which is read at a central location and known only by a few members of the company.

Oxonica director of chemistry Dr. Sharron Penn says the nano bar codes are a complementary technology to radio frequency identification (RFID) and competes on cost with the other taggant technologies available.

Advanced Coding Systems Ltd. (ACS [www.acs-coding.com]) in Israel has developed near-nanoscale bar codes that do not need to be on the outside of a package to be scanned. The company will trial these high-tech authentication and track-and-trace features, which are called DataFiber, within nine to 12 months.

The company has developed and tested the technology, but they don't yet have the capacity to produce it on a large scale. ACS is now working on the development of a commercial manufacturing process; the company says the engineering work has already begun. ACS president Yoav Dvir says that ACS is talking with several interested parties, including brand owners and governments, about use of the DataFiber.

The DataFiber solution uses ACS's magnetic MicroWire technology to create a covert code within an item or its packaging. The code provides authentication as well as track-and-trace information such as ID, batch number and expiration date. Unlike RFID solutions, the DataFiber tag is not compromised by metallic materials such as aluminum, magnesium, copper, bronze or brass. The DataFiber tag is made from several glass-coated magnetic MicroWires, which can be produced with a very small diameter, ranging from few microns to tens of microns, from a variety of magnetic and nonmagnetic alloys and pure metals. These MicroWires are placed on a tag that can be about 15330 mm, and will therefore fit on most product packaging.

The DataFiber reader can read the tag somewhat like an RFID reader reads an RFID tag. The reader contains a magnetic analog circuit for generating a magnetic field, and it receives the wires' re-magnetization pulse response. The reader can be mounted on a production line, or it can be hand-held.

Despite the fact that the DataFiber tags share similarities with RFID tags, Dvir says they are not competing technologies. He believes DataFiber can work alongside RFID. He says that one thing that differentiates the two technologies is the price—when the tags are commercialized, they will cost less than $0.06 each.

While much of the technology discussed in this article has not yet been commercialized, there are some important partnerships in the works, indicating that businesses are investing in the future of the technology.

Applied DNA Sciences (ADNAS [www.adnas.com]), a botanical DNA security solutions company in Stony Brook, NY, recently signed a memorandum of agreement with DataFiber maker ACS. The partnership calls for the companies to develop new security products that marry ADNAS's proprietary botanical DNA security technology with ACS's patented technology. ACS will exclusively manufacture the new MicroWire products embedded with DNA, and Applied DNA Sciences will exclusively market the new products worldwide.

The collaboration is to develop a DNA-embedded Digital Magnetic Identification Device (DNA-DMID) that will be a DataFiber tag and a reader, and will incorporate botanical DNA. The ADNAS botanical DNA is encapsulated in tiny particles, designed to withstand heat and pressure, using nanotechnology. The reader, already developed by ACS, has the ability to read directly through the walls of cartons and containers and identify the contents inside. The DNA-embedded MicroWires can be integrated into product packaging, cartons, paper, tags, clothing, passports, security documents and virtually any product requiring identification.

Dvir of ACS says, that DNA-DMID will provide an instant, low-cost security technology for the global anti-counterfeit and brand-protection market. "Our existing product lines will now be enhanced by the forensic qualities provided by Applied DNA Sciences," he says.

The two companies say that when these products are released, they will provide covert coding-based solutions for a wide range of industries, including homeland security, pharmaceutical, beauty products, luxury goods, automotive, and fine art and collectibles.

Nanotechnology for brand-protection is expected to grow exponentially over the next five years. But with the new technology mostly confined to the lab, the market can only grow. The technology is so new that tests have not yet revealed positive or negative results. In addition, nanoscale protection can vary from $0.06 to $1.25 for each item, and since authentication technology is available at a lower cost elsewhere, that price is more than most end users want to spend. There is still work to be done before the technology will be adopted.

Reprinted with permission from Pira Intl., this article was written by Rebecca Roberts for the 2006 edition of Pira's "Profit Through Innovation." The publication is a collection of articles published by Atalink Ltd. on behalf of Pira, exploring the latest technical developments and trends in the printing, packaging, publishing and pulp and paper industries. For more information on Pira and its publications, visit www.pira.com.uk or call +44 (0) 1372 802000.

More information is available

Advanced Coding Systems Ltd., 972 9 891-1831. www.acs-coding.com.

Applied DNA Sciences (ADNAS), 631/444-6862. www.adnas.com.

NanoInk, Inc., 847/679- 6266. www.nanoink.net.

National Physical Laboratory (NPL), 44 20 8977 3222. www.npl.co.uk.

Oxonica Inc, 650/603-5900. www.nanoplextech.com.

You May Also Like