Filling machines—the core of most packaging lines—usually set the pace and character of a packaging operation. Modular designs in recent years have added some flexibility, and boosted delivery lead times. But a new concept in how fillers are built may upend how bottle liquid filling systems contribute to elite packaging operations.

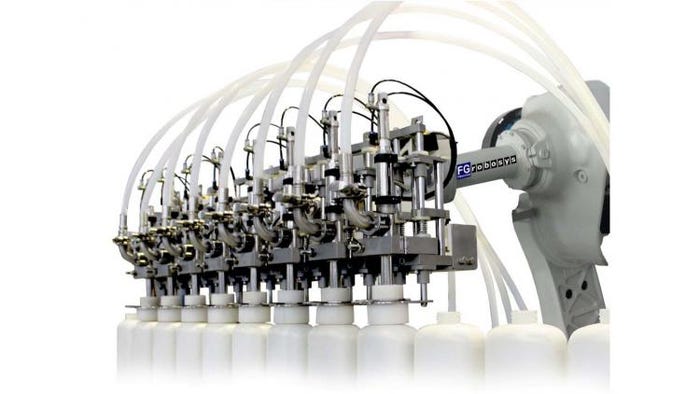

The Robofiller from Fillomatic Global (FG) Industries uses a robotic arm for on-the-fly intermittent-motion liquid filling that reaches speeds up to 200 containers per minute with 10 filling heads.

The benefits of this particular filling system design are courtesy of John Henry, Certified Packaging Professional (CPP), owner of consultancy Changeover.com, author of multiple packaging-related books including “Packaging Machinery Handbook” and KC Boxbottom blogger for Packaging Digest:

1. Flexibility: “Change the head and you have a whole new filler,” Henry says. The company touts the system’s speedy changeover, describing it as “instant,” and referring to either product or package format changeovers.

2. Cost: “Rather than a custom-built filler,” Henry says, “you have a standard robot that costs around $50,000.” FG Industries offers a variety of mix-and-match modules: bottle handling, bottle positioning, conveyor systems, filling nozzles, filling engines, filling parts materials, product delivery systems and ejectors.

3. Delivery time: “Robots are essentially off the shelf,” Henry adds. The modular design of the entire system also contributes to fast machinery delivery, helping you get your project up and running on time.

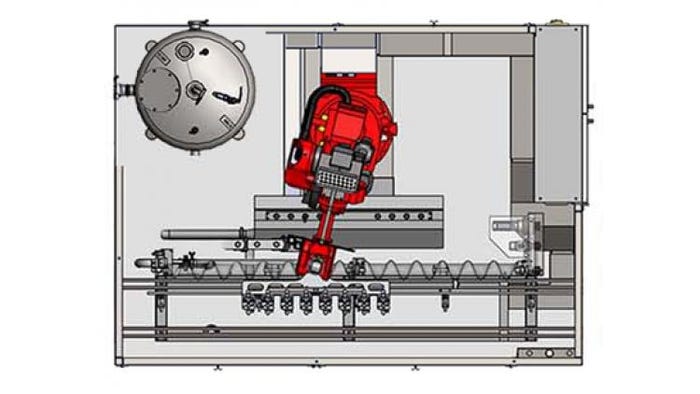

4. Size: “The system is fairly compact,” Henry notices. One such filling system, the X8 S8 series, measures approximately 9.5 feet wide x 6.875 feet deep and 6.875 high.

FG Industries also makes plug-and-play robotic induction cap sealers and cappers to create a complete packaging system (RoboSys) for a variety of liquids, including foods (sauces), beverages, pharmaceuticals, personal care products, household and industrial chemicals, and more.

About the Author(s)

You May Also Like