November 18, 2014

|

How would you safely package and transport a 77-million-year-old, mummified dinosaur? Sealed Air Corp. (www.sealedair.com) knows how to do it, and it answers with a resounding, “very carefully.”

In fact, the job was such an amazing and unusual one, that Sealed Air and its dinonsaur story are the subject of a Discovery Channel television network episode called, “Secrets of the Dinosaur Mummy,” which aired on cable television in September.

Leonardo, a duckbilled (Brachylophosaurus Canadensis) dinosaur that roamed the earth all those millions of years ago, was found in 2000 in Montana, almost completely intact. Ninety percent of his body is covered in skin, which meant that a remarkable preservation existed. The fossil hunters know what he ate for his last meal, which consisted largely of leaves, including ferns, magnolias and conifers. A four-legged, three- or four-year-old (when he died), he is also one of the most unexpected and important dinosaur discoveries of this age, they claim.

He was found by a team of amateur geologists and paleontologists who were exploring the town of Malta, MT, and named him Leonardo after seeing some graffiti on a boulder near where he was discovered that read, “Leonard Webb and Geneva Jordan, 1917.”

|

Encased in rock, the dinosaur fossil was shrink-wrapped in a film and shipped in a foam-cushioned crate. |

The crew of more than 25 volunteers, which founded what is now the Judith River Dinosaur Insitute (JRDI), actually discovered what it believes is the first dinosaur mummy with intact digestive tract contents—a once-in-a-lifetime discovery.

Scientists have more than just its skin and bones to fully reconstruct how Leo looked and lived. With fossilized samples of the digested food still inside the viscera, plus its joints, the team of scientists also was able to create a reconstruction of the giant dinosaur, accurately, both inside and out, which they claim is a first.

Suspecting there would be fossilized organs within the dinosaur's torso, the team members agreed that the remains needed to be scanned at the National Aeronautics & Space Administration (NASA) in Houston. So Leo, who was incredibly preserved through the eons in rock and weighs two tons, would have to be moved 2,000 miles to NASA's Johnson Space Center where he could be studied further using state-of-the-art equipment.

A member of the science team solicited help from Sealed Air packaging experts to create a protective package that could safely transport Leo. The entire journey was recorded for the Discovery Channel documentary.

You want to ship what?

|

With a final packaging design strategy, the packing team hand covered the fossil with a shroud of protective film over its exposed surfaces so that if anything dislodged, it could be repaired later. |

But flying the specimen's remains to NASA in Houston was out of the question, the team realized. The nearest airport of any size was in Billings, MT, more than 200 miles away.

Such a trip would require multiple handlings on and off vehicles and aircraft, which would have been outside of the team's control. Leo would have to be shipped by truck.

Funded primarily by various donations, sponsorships from industry and other private and public sources, donations of time and materials for the packaging portion of the project and the rights provided to the television production group to create the eventual Discovery Channel program, the packaging portion of the project began taking real shape when Art Anderson, a member of the science team, started to look for a way to package the mummified dinosaur gently enough to withstand truck transportation.

|

A shock-insolation system was designed to sustain the 4,000-lb specimen using foam padding on which the entire crate rode. |

The packaging request was definitely the most unique that Bill Armstrong, technical development manager at Sealed Air, says he has ever received. “It was a true chance in a lifetime,” he says. “We had use of a specific vehicle and we oversaw all loading and unloading operations. It was felt that shipping the specimen by air would have been too complex and risky for our purposes.”

Armstrong led the packaging end of the project, which included designing, testing and implementing a package to transport the irreplaceable artifact across the country. He assembled a team of packaging experts from Sealed Air, the International Safe Transit Association [ISTA (www.ista.org)], Lansmont Corp. (www.lansmont.com) and the U.S. Navy to create a custom containment design. The team worked throughout 2007 to create a custom solution with the support of Sealed Air's Packaging Dynamics Lab in Danbury, CT. Armstong led the team in planning and made several trips to Malta. The packaging team then traveled there in February 2008 to execute a design it finalized in the Packaging Dynamics Lab.

Rocky but fragile surface

Before the fossil could be shipped, however, the science team spent several days preparing and stabilizing the actual rock surface of the dinosaur. After the time spent exposing the surfaces to the point where further study could be possible, many parts of the actual surface of the specimen were quite exposed and fragile. “The specimen wasn't a solid hunk of granite—it was a soft, sandstone-like composite,” Armstrong remembers. “I recommended that we shrink-wrap by hand a shroud of CorrTuff film over the exposed surfaces so that if any piece or component of the top plane of the specimen were to become dislodged, it could be kept in place for recovery and repair upon arrival, should it so be needed. Luckily, when we arrived [in Houston], we noticed that the CorrTuff served essentially as an insurance policy only.”

|

The outer surface of the dinisaur specimen wasn't dry bone. Ninety percent of his body was covered in skin, a remarkable preservation. |

During their three days on-site, the packaging team assembled a base and a reinforced plywood crate on which the fossil would travel. Made of 4x4- and 6x6-in. lumber to provide a stable lateral support structure for what it now believes was a 4,000-lb fossil load, the wooden crate measured about 12.5-ft-long, approximately 4-ft-high and just a bit less than the width of the trailer used to transport Leo. The team also completed a shock-isolation mounting system on which the wooden crate would ride.

“The shock-isolation system we designed consisted of an external pad using resilient foam on which the entire crate would ride in the trailer,” explains Armstrong. “Consulting with several shock-mount system design engineers at the U.S. Navy Weapons Center at Colts Neck, NJ, we all agreed that for this particular set of challenges, such a system would be preferred for both development and assembly perspectives. Our objective in the shock-mount development, was to provide a design that would have minimum damage potential for the equipment, during the journey, had the product-response characteristics, etcetera.”

Foam, film, foam

|

After 'Leo' was shrink-wrapped,'he' was blocked and braced in protective PU foam packing, which expands up to 200 times its liquid volume in seconds. |

Leonardo was lifted off of its supports in the JRDI field station and mounted onto the base for transport. Next, it was shrink-wrapped in Sealed Air's CorTuff® high-abuse shrink film to stabilize its fragile surface. The shrink film is strong enough to withstand high abuse and is often used with such items as rugs and other textiles and building materials, Sealed Air reports. The film works with a wide range of product shapes, weights and sizes, from large consumer goods to odd-shaped item, so was most suitable for the odd-size artifact pieces in this case. The wrapped fossil was blocked and braced using Instapak® PU foam cushioning and placed in the crate. The Instapak foam-in-place material expands up to 200 times its liquid volume in seconds to form protective cushions.

The packaging team carefully moved the assembled crate to the trailer and mounted it atop a shock-isolation system, layered with 3 in. of Sealed Air's Stratocell® H PE foam. Featuring up to 6 in. of thickness in half-inch increments, Stratocell H foam provides cushioning protection against repeated shock and cushions light or heavy objects.

|

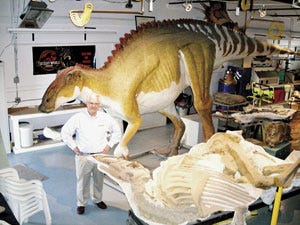

Packing team leader and Sealed Air's techinical development manager Bill Armstrong stands in front of a replica of Leonardo and behind the actual dinosaur fossil itself. |

“The basis for the shock-mount performance was in the use of the Stratocell H foam,” Armstrong explains. “We asked Lansmont if they would support our development through the use of some of their transportation environmental measuring systems in a test-ship program, using the actual tractor/trailer equipment that would be used in the eventual shipment.”

Lansmont agreed, Armstrong tells PD, and the test shipment—750 miles each way from Malta to Ogden, UT, and back—was executed in August, 2007. The information gained from that test was then used to support the design of the ultimate shock-mount assembly.

Development work at the Sealed Air Packaging Dynamics lab included a review of Lansmont's vibration data from the test shipment.

Sealed Air provided the materials, the design, the development and testing for the crate, shock-mount assembly and interior packaging, blocking and bracing as part of its overall sponsorship of the project.

The team then created what Armstrong defines as a transmissibility protocol using what the team felt would be a representative vibration level and composition for the shipment. “We tested several different foam alternatives as far as density and thickness goes, and found that Stratocell H provided the best combination of resilience and vibration performance for these conditions at the required thickness and loading parameters,” he says.

No sand out of place

After the 2,000-mile trip by truck, “not a grain of sand was out of place,” according to one of the scientists. Upon arrival in Houston, the science team began scanning the fossil to determine if any fossilized organs were present. The crate was gently removed from the truck into a NASA hangar where it was finally opened.

|

Lifted by forklift off of its supports at the Judith River Dinosaur Institute field station. |

The scanning took place under strict security, and the findings were revealed when the documentary—being filmed throughout the process—aired worldwide on Sept. 14.

“An opportunity like this is rare,” Armstrong sums up. “Working with a team of experts to transport a 77-million-year-old, irreplaceable item was beyond my wildest dreams.” At that time, the team didn't yet know what the scientists found inside the fossil, Armstrong points out, “but we know nothing was displaced during transit. We had to watch the documentary to find out what was revealed. I would, at best, paraphrase my understanding of what the scanning team and overall science said in the program, but the team seems to have found at least a couple of organs, in addition to a lot of information on the digestive tract of this creature, etcetera. From what I understand, the team feels that they have found the liver and what is very likely to be the heart of the dinosaur, judging by their scans.”

On exhibit

|

Leo was then mounted onto the transport system system. Stabilized and braced for the long trip, the shipment then headed to NASA without a hitch. |

An extraordinary archeological find, the mummified Leonardo, with more than 90 percent of its body covered with fossilized soft tissue, is one of only four existing Brachylophosaurus specimens unearthed to date.

Starting on Sept. 19, 2008, Leonardo went on display at the Houston Museum of Natural Science in a specially created exhibit.

According to Armstrong, the JDRI was founded to provide the location and resources necessary to continue to develop the science part of the project. The actual discovery site had once been a tire store at one of the main intersections in the middle of Malta.

The facilities also provided tours and visits throughout the summer so that individuals could stop in to see the fossil as working scientists continued to reveal and study what they had unearthed.

More information is available: |

Sealed Air Corp, 201/791-7600. www.sealedair.com. |

International Safe Transit Assn., 517/333-3437. www.ista.org. |

Lansmont Corp., 831/655-6600. www.lansmont.com. |

About the Author(s)

You May Also Like