A new 3D printing solution lets you print packaging machine parts as easily as you stream music on Spotify. No skills are needed to click, print, and install the part you need.

October 14, 2020

When you want to hear some music, there’s a good chance you’ve used an online streaming service such as Spotify. You just select a song and click to play.

What if it were just as easy to do the same thing when you need a part to keep your packaging machine running? “What-if,” it turns out, is right now.

A new click-to-print system is now in use that can bring your packaging operations an additive manufacturing (3D printing) solution that combines the simplicity of music streaming with the sci-fi conveyance of “using a replicator from Star Trek,” says Marcus Schindler, supply chain director for Gerhard Schubert GmbH, packaging machine builder for Nestlé, Unilever, Roche, Italian confectioner Ferrero, and other consumer brands.

Major benefits touted by proponents of additive manufacturing include reduced tooling costs; greater control and innovation over part designs; greater manufacturing precision; faster design revisions/iterations; shorter lead times and reduced deployment time; and less waste for greater environmental sustainability. As the method matures, the price/performance ratio points to more and more solutions that mate the right materials and printers to provide new packaging line solutions.

“We are very convinced that on-demand manufacturing, and distributing manufacturing down to the customer, is a superior approach,” says Schindler, who is also co-CEO of Schubert Additive Solutions, a new sister company formed last year to develop a click-to-print solution for sending data instead of parts so customers can print their own, on-premise, within specialized knowledge of 3D design or printing. Instead, they browse their online parts catalog or “digital warehouse” account for the part they need, click, and printing begins automatically.

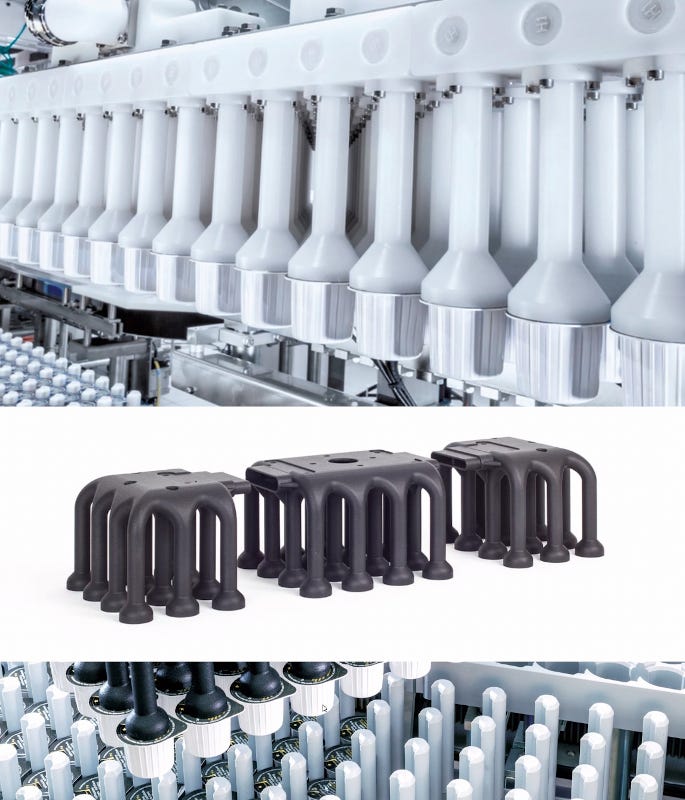

The parts can be standard replacement and spares already in the machine builder’s virtual stores, as well as customized tools for product and packaging format changeovers, such as robotic end-of-arm tools (EoATs).

The first installation came last year when a cosmetics brand installed the solution at its facility. While most details aren’t yet public, Schindler reports that a full set of format changeparts, from empty container to end-of-line, costs less than €1,000 using the on-premise 3D printing solution. See this cosmetic line and others in this video.

Since that installation, four more packaging lines have added the printers and five more early adopters have purchased the system for non-packaging applications.

For packaging customers, the system removes the technical hurdles to adoption. In fact, many are already using printed parts and may not know it. According to Schindler, the machine builder has used additive manufacturing in every machine it’s made since 2012 — from a few hundred to 45,000 last year and approximately 65,000 this year. Hundreds of thousands of printed parts are now running on packaging lines in the field.

How does it work?

The new solution, called Partbox, results from a partnership with additive manufacturing solution provider Ultimaker.

Here’s how it works:The user, such as an authorized packaging manager, logs onto their personal Partbox digital warehouse account (at partbox.eu), selects part(s) and quantities from the software catalog or “digital warehouse,” and clicks to print. That’s just about all there is to it beyond loading the material (see image below).

Schubert hasn’t stopped after-sale service and support, so it still sells parts, 3D printed or otherwise. Instead, it devised the Partbox system so that users can’t open and modify part files. On the upside, the system protects and guarantees the quality, safety, and performance of printed parts while protecting its own intellectual property. The closed-loop system is much like Apple’s iTunes music store in that it creates a walled garden of protected files.

Data communication, from software to printer to financial billing for parts is handled by a dedicated industrial Internet of Things (IoT) gateway developed by Schubert System Elektronik and genua GmbH, the German IT security subsidiary of the Federal Printing Office in Germany. This walled-garden approach eliminates the possibility of using a potentially infected USB stick to transfer files to the printer, and eliminates the cyber-risk of opening factory networks to the internet.

Schubert partnered with Ultimaker for its million-dollar/Euro-plus in-house machines that print metal and plastic parts, and for the Partbox, a scaled down printer is used to print standard parts from gears to EoATs with optimal price and performance.

Methods, materials, and money.

Schubert’s original parts use printing processes including selective laser sintering (SLS), which fuses polymer powders with resolution that matches injection molding. The Partbox printers use fused deposition modeling (FDM), which melts and extrudes thermoplastic filament (primarily polylactic acid or PLA with some use of polyethylene terephthalate gly or PETG). The level of strength and detail is optimal for format parts and the like, but costs far less — roughly €10,000-euro vs. €1 million.

No one machine can do everything: If a part is too large or otherwise unsuited to the Partbox, Schubert will revert to other 3D or traditional manufacturing methods and ship the physical parts. But additive manufacturing is without a doubt progressing to encompass broader applications. A case in point: Packaging Digest’s September report on a new laser-based techniqueto simultaneously use multiple materials to print a part.

Today, Schubert offers standard parts to all customers, while new, custom parts can be added to accommodate users’ plans for new products and formats. Schindler says cycle time for a part that would have taken three weeks using traditional methods can now take two weeks using 3D iterative designs. When a customer needs a new format part, Schubert designs, tests, and certifies the new part and then adds it to the customer’s Partbox account.

The speed of 3D printing has proven itself elsewhere. For instance, Heineken, independently of Schindler but also using Ultimaker printers, has found that if a part failure causes a stoppage on the bottling line, a new part can be printed in eight to 10 hours — from design to completion — as opposed to days (or much more, depending on global logistics) for a machine vendor to ship a part that’s already in stock. Isabelle Haenen, global supply chain procurement at Heineken, said last year that the company is “still in the first stages of 3D printing, but we’ve already seen a reduction of costs [per printed part] by 70% to 90% and also a decrease of delivery time of these applications of 70% to 90%.” (See video “Heineken: Ensuring production continuity with 3D printing”)

Reducing complexity makes better parts.

“Complexity is free,” says Schindler, referring to the new, optimized part designs that 3D brings. “This is the secret of additive manufacturing. We can make better parts, and we can reduce the number of parts, and the time you need to assemble the parts. And we can design better, more efficient, lighter parts,” says Schindler.

3D modeling and iterative design can simplify and lightweight part designs to reduce wear, weight, and performance over traditional parts.

In one case, a new tooling design helped turn a machine with two robots, one for carton erecting and another for bottle filling, into a one-robot process, Schindler says. Elsewhere, new tool designs that slide and clip into place speed changeovers on cosmetic compact-packaging lines, and bottle fillers — a single part can be swapped in seconds, reducing complexity and speeding format changes. This, and the addition of color-coded tools make it simple to change between chocolate bunnies to chocolate Santas.

In another application success, a new 3D design for a robotic tool provided surprising benefits over a complicated EoAT assembly on a coffee creamer-cup line. Before 3D design, the tool was made of 192 smaller, CNC-milled parts with 1,000 screws, and took a full day to assemble and mount to the robotic arm. The new 3D design uses only three parts and only eight screws.

“Additive manufacturing reduces the process cost enormously, but most companies do not see the full cost-saving effect until they calculate the full process cost,” Schindler says. These include storage, production uptime, line/labor productivity, and other factors. In the area of transportation, Schindler says the 3D solution reduces carbon footprint per printed part between 40% and 89% because there are no parts to be shipped. The savings were calculated as part of an employee’s Masters thesis investigating touchpoints from raw materials to shipped parts vs. printed parts.

Schindler says he is now in conversations with “very large companies,” and that customers in the US have shown great interest and are “far more open” to the technology than European customers. He adds that a not-uncommon reaction from packaging professionals who see the solution in action is something like: “Whoa! This is cool.”

About the Author(s)

You May Also Like