Turn an engineer loose at the Automate trade show (Mar. 23-26, Chicago) and he’ll happily walk aisle after aisle looking at all the new technologies and applications. John Henry, owner of Changeover.com and author of the KC Boxbottom Adventures in Packaging blogs, spent two days there talking with exhibitors to discover the newest automation tools. He reports on highlights of what he saw—a baker’s dozen of goodies for fellow packaging engineers.

Starting with…

1. Rethink Baxter robot: Rethink Robotics displayed its Baxter collaborative robot shown here shaking hands with the author. A robot with two arms and three vision systems for $25,000? Sounds like a game changer to me. Baxter has a new brother named Sawyer. Sawyer is a bit shy and did not come to the show but I hear good things and look forward to meeting him.

Click “Next”

2. Datalogic low-cost vision inspection system: Remember when vision inspection systems cost $50,000 or more? It was not that long ago. Datalogic Automation’s VSM monitor/DataVS2 camera combo were detecting and rejecting cocked caps, low fills and improper labeling. And the complete system is less than $2,000.

Click “Next”

3. Adept Lynx AIV: Adept Technology’s Lynx is a new class of autononomous delivery robots. The Lynx is not an AGV (Autonomous Guided Vehicle) but an AIV (Autonomous Intelligent Vehicle). AIV technology means that it is self-guiding based on an internal map of the area which it is initially taught but then continually updates from experience. AIV means there are no floor magnets or wires or overhead beacons.

Click “Next”

4. Schneider Packaging gum tape case sealer: Schneider Packaging Equipment showed its new SR5000WAT case sealer. This combines two features to make this one of the more versatile sealers on the market. First, it seals with water activated (gummed) tape for a stronger, more reliable seal. Second, it automatically adjusts to random size cases. This allows it to serve multiple packaging lines or a distribution warehouse.

Click “Next”

5. Fanuc bin picking robot with 3D vision: 3D vision systems allow robots to identify the location of a part in three dimensions. This allows “bin picking” or finding, grabbing and orienting parts that are jumbled at random in a bin. Several companies were showing variations on the theme. One that caught my eye was this Fanuc robot picking caps at random from a pile.

Click “Next”

6. Yaskawa palletizer/depalletizer with Kinect 3D: The Yaskawa palletizer/depalletizer uses 3D vision to locate the position and orientation of the next case to be handled. The wow! factor was that instead of a $10,000 to 20,000 industrial vision system, they used a $150 Kinect game controller (highlighted) from Microsoft’s Xbox game system. I predict that, in coming years, Microsoft will sell many more Kinects than Xboxes as 3D vision gets incorporated into many applications previously not thought possible.

Click “Next”

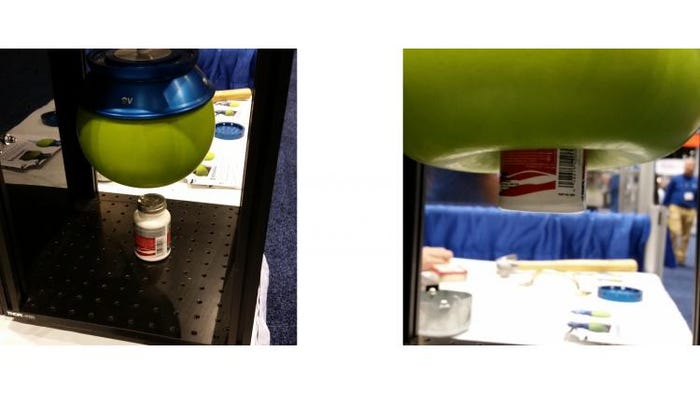

7. Empire Robotics Versaball Gripper: Empire Robotics’ Versaball gripper uses a soft pad to gently grip the package. It looks like it might be useful on odd shaped packages, such as cosmetics and fragrances.

Click “Next”

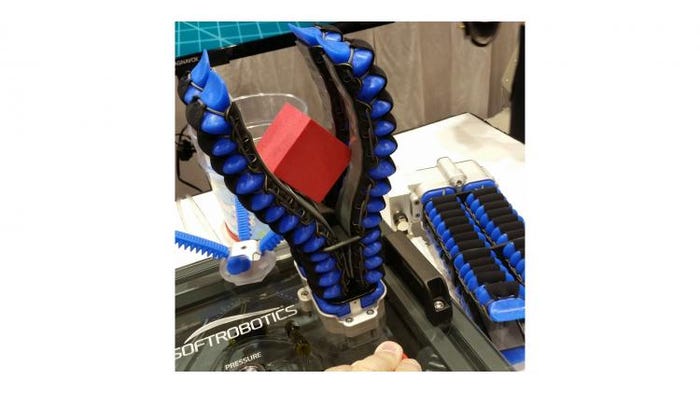

8. Soft Robotics gripper: Things like grippers may seem boring compared to the robots themselves but can be a significant cost. Soft Robotics was showing an interesting low cost, extremely gentle gripper. It uses inflatable fingers to grip the parts.

Click “Next”

9. Pretty robots: Some of us have always found robots to be beautiful but they did look like industrial machinery. I noticed a trend at Automate toward a more aesthetic, less industrial, design. Sleek smooth finishes and rounded corners, some of them would look more at home in the living room. My living room anyway. (Clockwise from top left: Kawasaki, Kuka, Nachi, Staubli)

Click “Next”

10. Fast switchable vacuum generator: Compressed air is always expensive and many packaging machines waste a lot of it with venturi vacuum generators. Piab’s PiCompact is an all-in-one switchable vacuum generator. High cycle rates mean that compressed air is only used as needed.

Click “Next”

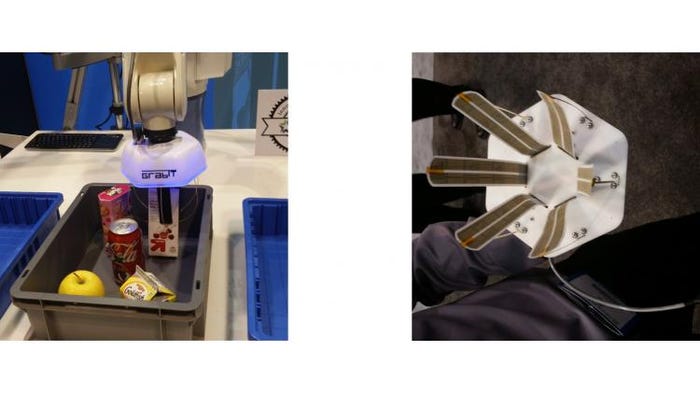

11. Grabit grippers: Another gripper that lends itself well to gentle random picking is this one from Grabit. It differs from most grippers by using static electricity. The fingers cling to the package when energized. Ultrathin fingers allow access to tight spaces where more conventional grippers can’t go.

Click “Next”

12. Universal collaborative robot: Collaborative robots were shown by several companies including Universal Robots (shown). According to Pat Davison, director of standards development for the Robotic Industries Assn., this is a bit of a misnomer. It is the applications that are collaborative rather than the robots themselves. Nevertheless, collaborative generally means that the robots are capable of working side-by-side with people. These Universal Robots are precise, fast and can be used without guarding in some applications. Compact size means that they can be mounted anywhere.

Click “Next”

13. Liftoff castors: Sometimes it’s the simple things that catch my eye. The Footmaster castor from Foot Master North America combines a castor with a ratcheting lift-off and is intended to replace locking castors. The lift-off provides leveling capability as well as more security against movement. It’s suitable for machines that are moved from line to line.

That concludes our coverage of the Automate portion of the show housed in McCormick Place's North Hall; to see highlights of the ProMat show in the South Hall see 6 distinctive downstream packaging systems at ProMat.

About the Author(s)

You May Also Like