May 13, 2020

Because of COVID-19 travel restrictions and social-distancing requirements, many packaging machine builders are supporting their customers remotely now using a variety of technologies. Here are six options.

Most of America may be on lockdown because of the COVID-19 pandemic but essential manufacturing lines are still running. They need support from their packaging machine builders.

Field service is always expensive. Travel is one big cost. More costly yet is response time. Under the best of circumstances, it can take 24 hours or more to get a tech on site. What product manufacturer, even in normal times, can afford 24 hours of a machine being down?

Many packaging machine builders are supporting their customers remotely now using a variety of technologies. Here are six options:

1. PLCs connected to the internet.

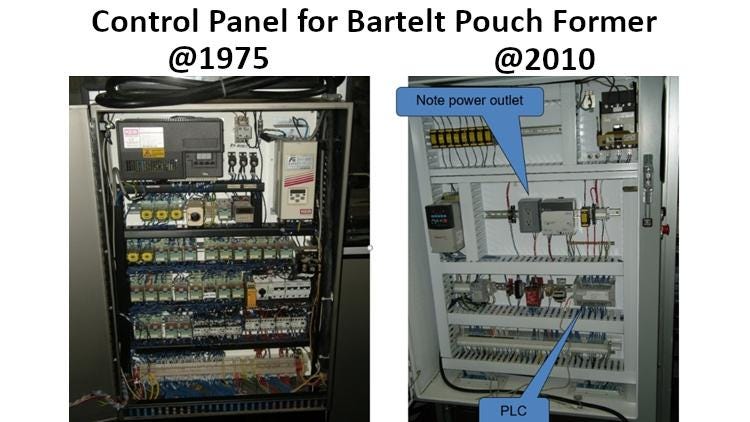

Programmable Logic Controllers (PLCs) became popular in the 1980s and 1990s. They replace electro-mechanical controls, as seen at left in the photo below, with a small electronic box. Instead of tools, meters, and patience, troubleshooting is done using a laptop. It quickly became obvious that the laptop didn’t need to be at the machine but could be thousands of miles away. Initially with dial-up modems connecting to the internet, most modern machines allow remote troubleshooting.

Photo courtesy of Frain Industries.

2. Smart sensors.

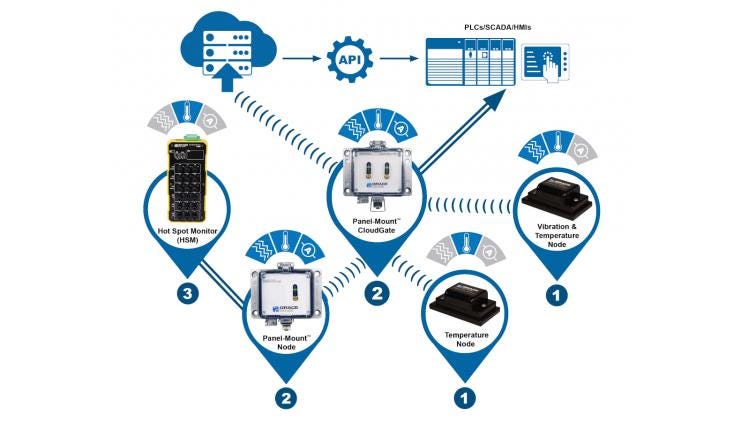

High-speed networks, secure, always on VPN connections, and the cloud have enhanced this further. Some builders like ABB Robotics’ Ability Connected Services provide 24/7 monitoring of machine conditions and can notify of problems before they occur. Smart sensors, such as the GraceSense (see photo below), can continuously monitor temperature and vibration, and wirelessly send an alert locally or around the world before, rather than after, failure.

Photo courtesy of Grace Technologies.

3. Standalone internet of things (IoT) devices.

When the plant manager is working from home, they can’t tell what is happening on the packaging line. Is it running or down and why? Production output, rejects, and efficiencies are some of the data that can be accessed remotely via laptop, tablet, or smartphone. Systems range from the complex to simpler systems like this XL from Vorne. It will even send text or email notification when the line is down, running slow, or other trigger-events occur.

Photo courtesy of Vorne.

4. Smartphone apps.

Telepresence lets you be there without actually being there. We all have a camera in our pockets. With our smartphones, we can share what our camera is seeing, in real time, anywhere in the world. When a machine acts up, our phone shows the builder’s technician, even thousands of miles away, what’s happening. Language barriers and machine nomenclature no longer matter. They see what we see.

But wait, there’s more.

Help Lightning calls its app “Merged Reality.” The local tech focuses his or her phone or tablet on the area of interest. The remote tech not only sees this but can interact on the local phone screen. In this picture, we see the plant tech aiming the phone, and, on the local phone screen, the remote tech pointing something out.

Photo courtesy of Help Lightning.

5. Wearable connected headsets.

A number of companies make wearable headsets with embedded Android computers. RealWear is one (see photo below). Epson is another. Voice commands allow the wearer to pull up manuals, drawings, and more in the Heads Up Display (HUD) eyepiece. When they get stumped, assistance is a Skype call away. The built-in camera shows the remote tech what the local tech sees. The earpiece and mic allow them to discuss what is going on and what to do.

Photo courtesy John R. Henry.

6. Mixed-reality headsets.

JLS Automation has taken it even further, incorporating Microsoft’s HoloLens 2, an untethered mixed-reality headset, into its service repertoire. JLS president Craig Souser calls it “dumbed-down troubleshooting.” Unlike RealWear and other systems, the HoloLens allows the remote tech to be holographically present with the local tech. It may be the closest thing possible, at least today, to actual physical presence.

The lockdown has driven home that distance is no longer a barrier to service. Being there may be nice but no longer necessary in many cases. Distant assistance, remote monitoring, telepresence, and other future technologies will increase efficiencies by reducing downtime — and will reduce costs by eliminating delays in getting a tech onsite.

Bad as COVID-19 is, this shows that every cloud has a silver lining.

About the Author(s)

You May Also Like