When you (literally) hit a wall when laying out your packaging line, you could get creative Tetris-style. But that might introduce gaps or other hiccups at transfer points, which could limit line speed and, hence, output. Or you could just buy smaller equipment that fits in the space you have!

“Compact” is fast becoming a necessity rather than a nice-to-have in packaging machinery. Another benefit—especially of systems designed from the ground up to be smaller—is that the internal workings are often engineered to be simpler, with fewer parts and less complicated mechanics. And that translates into easier maintenance and less money spent on replacement parts.

From previews of products to be shown at the upcoming Pack Expo Las Vegas 2019 show (Sept. 23-25; Las Vegas), Packaging Digest presents 9 packaging systems that tout their small size:

Page 1: ReadyPack case packer from Somic America, Booth US-7346.

Page 2: FLX AXIS-Servo Linear pre-made pouch filler/sealer from AlliedFlex, Booth LS-5919.

Page 3: HMT-Mini case sealer from Massman, Booth C-2414.

Page 4: The lightline series Flowpacker line from Schubert, Booth US-7649.

Page 5: Model CSB vertical form fill seal (vffs) bagger from Triangle Package Machinery, Booth C-2614.

Page 6: Compact 12 monobloc from Marchesini, Booth N-107.

Page 7: RC10 palletizer from FlexLink, a Coesia company, Booth C-4400.

Page 8: ZX600 case packer from Bradman Lake, Booth C-4640.

Page 9: New Quik Pick & Pack robotic pick-and-place cell from Quest, A Pro Mach company, Booth C-3026.

1. Entry-level system simplifies retail-ready case packing (see photo at top of page)

The new ReadyPack case packer from Somic America (Pack Expo Las Vegas 2019 Booth US-7346) creates shelf-ready packs in a reduced footprint of 79 inches in length and 118 inches in both width and height.

Depending on the product being packed, ReadyPack can collate at speeds of 160 products per minute. As a tray packer, it will run up to 18 packaging units per minute; the wraparound model delivers 12 units per minute. Granted, the ReadyPack collates products, packs them and seals cases at speeds slower than the company’s 424 T2 (D) and the SOMIC FLEXX III that debuted at last year’s Pack Expo. But the new system has a simpler application than its predecessors and a shorter lead time, which Peter Fox, svp of sales for Somic America says are “two things that potential customers had expressed interest in.”

Fox adds, “People are used to seeing our other machines running at speeds three or four times faster, but they liked the simplicity and user-friendly capabilities.”

2. Entry-level filler/sealer handles pre-made pouches

The new compact FLX AXIS-Servo Linear pre-made pouch filler/sealer from AlliedFlex (Pack Expo Las Vegas 2019 Booth LS-5919) produces up to 20 pouches per minute in a footprint of 67 inches long.

With a fast changeover design, the system can be matched with various filling technologies, including weighers, augers, pumps and other feeders to accommodate the needs of the product being packaged. The system can handle pre-made pouches and bags made of laminated, recyclable, compostable and biodegradable materials.

3. Modular case sealer adds production flexibility in a mini size

With its modular design, the HMT-Mini case sealer from Massman (Pack Expo Las Vegas 2019 Booth C-2414) lets users pick specific features they need now, with the option of switching them out as production demands change down the road without having to invest in a new sealer.

The modular design also allows the company to cut delivery time of this top sealer by 50%.

With a footprint of 110 inches in length and 36 inches in width, the HMT-Mini seals standard cases (up to 18 inches long, 16 inches wide and 16 inches deep) using either glue or tape at speeds of up to 1,500 cases per hour.

4. Flowpacker + compact cartoner = a smooth running line

The lightline series Flowpacker line from Schubert (Pack Expo Las Vegas 2019 Booth US-7649) will be installed at a North American baked goods manufacturer after the show. The line is actually three compact and modular machines in one: A lightline Flowpacker, a lightline Pickerline (with pick-and-place robotics) and a lightline Cartonpacker that erects, fills and closes cartons.

The Pickerline measures 3.5 x 2.5 meters (around 11 x 8 feet). The Flowpacker and Cartonpacker are sized to production output needs.

Benefits of the preconfigured but scalable machines include fast delivery, affordable prices and smooth integration between systems.

Hartmut Siegel, CEO Schubert North America, explains in a press release, “The machines’ modular design, along with their advanced mechanical design and intelligent control systems, ensure exceptional effectiveness.”

5. Narrow-frame bagger makes packs up to 13 inches wide

With just a 36-inch wide frame, the new Model CSB (Compact Sanitary Bagger) from Triangle Package Machinery (Pack Expo Las Vegas 2019 Booth C-2614) can run bags from 2.5 inches up to 13 inches wide in various package formats, including pillow, gusseted and stand-up styles. The system accommodates a 27.5-inch film roll.

Two baggers can share a single scale to nearly double the output. Depending on bag length, the intermittent-motion vertical form-fill-seal machine can run up to 70+ bags per minute or 120+ bpm in a twin configuration setup.

Designed to be cleaned in place, the CSB offers other sanitary benefits, including solid stainless-steel bar for the frame that is fully welded and electropolished after welding, and IP67 food-grade servo motors and sensors for washdown.

See a 360-degree view of the system here.

6. Pharma monobloc combines multiple packaging operations in small footprint

The new Compact 12 monobloc system from Marchesini (Healthcare Packaging Expo 2019 Booth N-107, co-located with Pack Expo Las Vegas) fills and caps bottles for pills, tablets or capsules at speeds up to 55 bottles per minute (3,000 per hour). By integrating multiple operations on one machine frame, users can save floorspace, as well as guarantee total product control throughout packaging. The monobloc measures 2.4 meters x 1.16 meters (7.8 x 3.8 feet).

For quality control, safety and upmost accuracy, the machine’s HarleNIR vision system uses a Near Infrared (NIR) hyperspectral camera to chemically distinguish the pharmaceutical products by analyzing their active ingredient. This is in addition to its Valida technology multivision inspection for checking the shape, size and color of the pills. According to the company, it is the first packaging machinery manufacturer in the world to implement the HarleNIR technology for packaged blisters.

The monobloc can be flexible in the types of filling and capping operations incorporated. For example, it can handle screw-on, press-on and crimped capping applications. Need to insert a desiccant or cotton? It can do that, too.

The Compact 12 filler/capper can be mated with the Model Sirio3 bottle feeder and the RO600 bottle labeler to create a full packaging line.

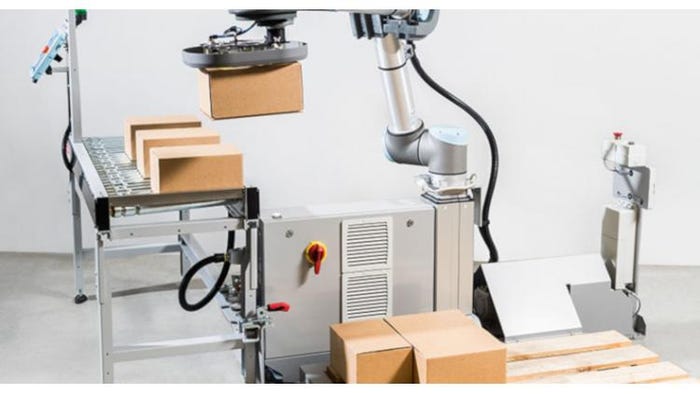

7. Cobot helps palletizer save space

A new version of the RC10 palletizer from FlexLink, a Coesia company (Pack Expo Las Vegas 2019 Booth C-4400), cut the footprint by more than 50%, compared to cells with industrial robots. With all the easy-to-install and -configure benefits of a collaborative robot (cobot), the standardized palletizing cell is also easy to move around the plant because it has an internal vacuum pump so no external air supply is needed.

This update includes sensitive paddings, improved robot program, user instructions in 18 languages and a shorter lead time to delivery.

Watch it in action here.

8. Robotic case packer offers minimal product-to-case clearance

The ZX600 case packer from Bradman Lake (Pack Expo Las Vegas 2019 Booth C-4640) uses an unusual robotic loader to minimize floorspace by shortening the product-to-case clearance. This also eliminates the need for an additional mechanical loading mask and associated size-change parts, which helps reduce inventory, changeover times and maintenance.

Designed for the pharmaceutical market, the ZX600 is enabled for aggregation, serialization and 21CFR compliance for full product and operator traceability.

See a video clip of the ZX600 case packer in action here.

9. Pick-and-place robot excels at case packing flexible packages

The new Quik Pick & Pack robotic pick-and-place cell from Quest, A Pro Mach company (Pack Expo Las Vegas 2019 Booth C-3026) can case pack up to 1,000 pieces per minute while taking up just 155 x 94 x 85 inches (L x W x H).

According to the company, “The Quik Pick & Pack works extremely well with flexible film packaging, thanks to its vision system and optional 3D scanning that quickly detects the pouches’ topography and center of gravity to identify the proper high point for picking.”

The system is “flexible” in other ways, too. It packs bags from 1 ounce up to 20 pounds and allows users to create custom pack patterns.

About the Author(s)

You May Also Like