February 9, 2016

Wisconsin packaging machine builder turns to Siemens for major project involving a world leader for beverage and dairy products; machine handles up to 850 single-serve 180mL bottles per minute

As with many things, this project started with a challenge. In this case, it was a major Original Equipment Manufacturer of filling and capping machinery for pharmaceuticals, beverages, household liquids, chemicals and petroleum products. It is of special note that the OEM has a long-time focus on dairy products.

The company’s liquid level and net-weight filling and capping machines are used worldwide. On a recent job for a customer of 40 years, a global leader in dairy and beverage production, the end user required a high-speed bottling and capping machine. Specifically, it had to process up to 850 bottles per minute or one bottle every 70ms, leaving a very small margin for any production errors.

The filler handles 180mL bottles of single-serve milk at a rate of 850 per minute. The machine was the first ever built by the OEM with all Siemens motion control hardware and software onboard.

The machine also needed to integrate with several other pieces of equipment on the production floor and feature simplified control architecture to facilitate easier operation, service and maintenance in the field. Those other pieces of equipment had Siemens controls, motors, drives, and human-machine interface (HMI) onboard.

It made sense that the customer mandated that Siemens components be used for this new machine.

The OEM’s engineering team conducted a thorough review of the available technologies to operate and control this machine, which represented several unique challenges. As one engineer explains, “We were using a drive technology that had a simplified motion control but couldn’t handle the speeds on this project. I had some experience with the requested brand of controls and so we turned to the Siemens Solution Partner in our area, DMC Chicago for consultation.” He also noted the end customer, while again impressed with the machine solution the builder had designed, was partial to having a brand of controls onboard that would be familiar to their operators and offer local support.

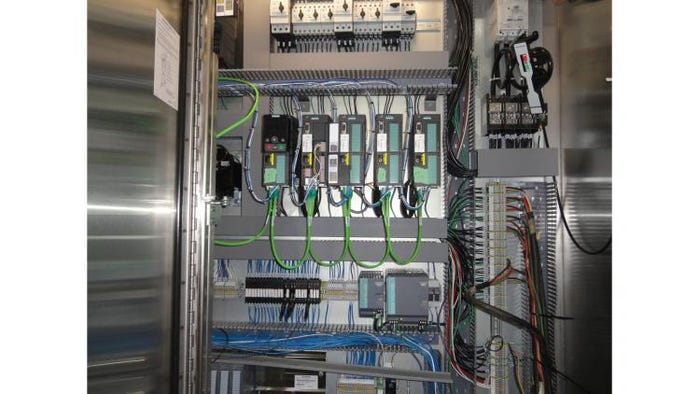

A look inside the controls cabinet reveals leading-edge components including Siemens Driv-CLIQ technology. Siemens motion controls run the entire machine--rinsing, filling and capping stations--and integrate to upstream washer and downstream package handling operations.

The controls chosen included a combination of SINAMICS G120 drives with power modules for each of the three axes of motion required, plus a 12-inch HMI Comfort Panel. At the heart of the system is the S7-1500 PLC with high-speed actuator timing and Process Image Partitions, a feature that allows substantially enhanced monitoring of the objects in process.

Configured on the Siemens TIA Portal with PLC Open command structure integration, the system allows the virtual synchronization of the three axes controlled by the drives, using a combination of positioning axis and synchronous axis technology objects. The high-speed actuators onboard handle the speed requirement, in this case, 850 bottles per minute.

“This machine was designed to process, clean, fill and cap 180ml single-serve milk bottles at very high speed,” says Brian McKittrick, the OEM account manager on the project for Siemens. “We worked closely with the builder’s team and Nick Shea at DMC, our Solution Partner, as well as Professional Control Corp., the local Siemens distributor, to design and implement the right answers for this project, including the selection of the PLC, Simatic HMI (shown below), motors and drives. The additional requirements for the power conditions in the end user’s foreign country were also considerations.

“In the end, the combination of products we supplied to support the considerable engineering talent at the builder created a machine that gets the job done, with minimal maintenance and easy serviceability onsite by the customer’s team.”

The machine provided is based on the builder’s gear-on-carousel design framework, which allows integration with the upstream cleaner and downstream packaging handling equipment in the end user’s highly-automated facility. Further featured on the machine are the Siemens Driv-CLIQ technology, which allows instant recognition of the absolute encoder positioning for faster and more accurate field commissioning on new motors, for example, plus the TIA Portal interface allows the configuration and on-the-fly adjustment of the HMI, PLC and all motion control functionality between the carousel, filler and rinsing stations of the machine.

The 12-inch HMI panel. Special features allow greatly enhanced monitoring of the objects for tight bottle-to-bottle control.

15 bays in 100,000 square feet

This builder operates from a 100,000 square-foot facility with approximately 100 employees and 15 bays of operation, in which all design, engineering, fabrication, assembly and testing occur. This project required nearly a year in development and is the first of several similar machines being provided to the end user under an ongoing contract agreement. The machine is also the first ever built by the OEM with all Siemens motion control hardware and software onboard. As one engineer notes, “This new system simplifies cabling, set-up and changeover times substantially, for both our customer and us.”

As a vertically integrated manufacturing facility, all the components of the machine are assembled or fabricated at the builder, including the company’s unique flexible filling valves and the channel support “smooth edge” welding technology on the stainless steel framework. Another highly valued department at this builder performs hand polishing of the cap runner channels.

As the company’s production manager explains, “These are among the many strengths we have in the market today and they keep us at the leading edge of machine building for the dairy and beverage industry, in terms of process stability, line integration, end product quality and machinery use life.”

The company typically produces FDA-approved machines with 3-A sanitary certification, HEPA Class 100 enclosures, plus automated CIP and SIP systems, sterile air and water, antimicrobial capping and integrated bottle rinsers. The company markets its machine solutions to the global packaging industry currently.

Ajay S Rana is involved in industry business development (packaging), OEM production machines and digital factory automations for Siemens Industry, Inc.

About the Author(s)

You May Also Like