Sign up for the Packaging Digest News & Insights newsletter.

March 11, 2015

1 Min Read

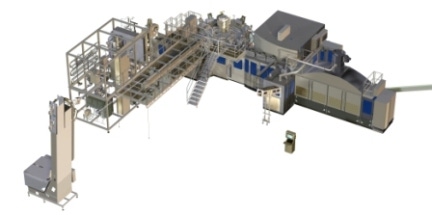

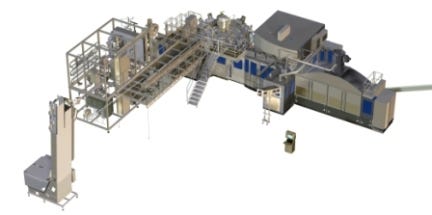

Combi Predis FMa aseptic bottle filler

Combi Predis FMa aseptic bottle filler

The company has released the high-speed Combi Predis FMa for aseptic filling of PET bottles. According to the manufacturer, the machine can handle up to 48,000 bottles per hour for small containers of up to 700 mL, used mainly for on-the-go consumption. The unit is designed for aseptic bottling of any kind of beverages, whether low or high acid: fruit juices, teas, isotonic beverages, carbonated soft drinks without preservatives, liquid dairy products and UHT milk. The Combi Predis FMa technology replaces bottle rinsing by dry preforms decontamination using hydrogen peroxide. The Predis dry solution reportedly does not require any water and creates no effluent, saving 250 cu. m of water and 200 L of chemicals used daily on a traditional aseptic bottling line. In addition, dry preforms decontamination also is said to cut annual operating costs by 30 percent compared to traditional dry bottle decontamination.

Sidel, 678-221-3027.

www.sidel.com

.

You May Also Like