March 11, 2015

|

QPSI prides itself on its innovation and flexibility. The supply-chain solutions company has specialized contract-packaging capabilities within a number of industries, including pharmaceutical, retail, promotional and sample packaging. In addition to its contract-packaging offerings, the company also sells direct-mail fulfillment and supply-chain solutions.

“The reason we cater to so many different industries and have so many different offerings is that it allows us diversified balance of our business in what is otherwise a very volatile type of business,” says Jeff Wozniak, executive vp of QPSI.

“We found over our history—and we were founded in 1972, so we've got quite a bit of history—that focusing on one niche within that industry, just one type of packaging, really limits growth and causes a lot of volatility. This makes it difficult to sustain profitability.” Having a diverse range of services and multiple locations, QPSI needs to have an efficient estimating cost accounting system.

For more than a decade, the company has implemented electronic estimating and cost accounting. This was through a homegrown, Microsoft Excel-based system that QPSI developed and improved over the last 15-plus years. The Excel-based system was utilized for the company's daily cost accounting and its daily activity reporting.

According to Jason Tham, CEO of software development company Nulogy (www.nulogy.com), homegrown solutions are not only common in the packaging industry, they often are a necessity. “Packaging is a highly underserved industry [by manufacturing requirement planning software developers],” he explains. “It's kind of a pain point that all packagers have. They manage it in their own way, because they have to.”

Approximately two years ago, QPSI began to research for a new way to tackle the estimating cost-accounting needs. Its Excel-based system didn't have the ability to output reports or give historical data, including historical profit and loss information, as it pertains to a project, equipment, the code, the package type or customer.

Instead, QPSI had procedures in place to do this manually.

Vetting the software and its developers

The contract packager first looked at some out-of-the-box software, but then decided it wasn't appropriate for its operations. QPSI then considered the arduous task of building an application in-house. “So we decided that we were going to develop our own system, and that entailed doing the design work, understanding the theory behind it, hiring a programmer and utilizing a lot of our own internal IT resources to pull together what we would need to do that,” says Wozniak. “We realized it was going to be a huge undertaking with high costs, a lot of risk and no guarantees.”

A few months into the project of building its own software, QPSI made an important connection at the PACK EXPO International 2006 show. QPSI corporate industrial engineer Nick Johnson had discovered the Nulogy group and its PackManager software. Johnson introduced the gentlemen from Nulogy to the QPSI management team, and the QPSI team was impressed. “They said a lot of the right things,” says Wozniak. “They said that their system and software could do everything that we were looking to do on our own and a whole lot more.”

Although QPSI was impressed by Nulogy's presentation, the company still did its due diligence on the PackManager software and the Nulogy team. In addition to its research independent of the Nulogy's team input, QPSI also required follow-up meetings with the software-development company before it could move forward with the PackManager implementation. This was a long and detailed process, it says.

Moving to the cloud

Finally in fall 2007, the management team at QPSI trusted that what Nulogy was offering was in fact “the real deal.” Within a year's time, QPSI has rolled out the application at two of its locations: one in Mechanicsburg, PA; and another in Moonachie, NJ. Nulogy has completed predesigned work to customize the application to QPSI's specific business needs, and the developers have done much of the customization already.

What QPSI gained with the PackManager software installation was more than the ability to quickly generate quotes. It also now has the ability go back and generate reports that give a fuller understanding of the cost accounting, and therefore operate more efficiently.

As a turnkey, supply-chain management software built for contract packagers, PackManager can deliver labor, production and inventory information in real time.

The latest version of the software is called PackManager Zero. The zero refers to the application footprint, maintenance and potential hassle for a contract packager's IT department. The application is provided using the Software-as-a-Service (SaaS) model based on cloud computing, where applications are served as web pages instead of being installed on company servers or PC terminals.

The cloud computing movement is gaining traction because of its potential to minimize upfront investments, manage costs to benefits on ongoing basis, reduced total cost of ownership and lessen the burden on IT departments.

Explaining how SaaS can be even less intimidating for users than installed applications, Tham comments: “One of the things we often ask is, 'Do you ever go to Yahoo or Google?” They respond yes. Then, we say, 'Well, what you are going to do is go to packmanager.net and log in with this. Look, that's your information; that's your enterprise.”

Have data, will travel

Contract packagers can use PackManager to search quotes and production history, copy old estimate and production data, mark up materials, labor and overhead, optimize the packaging line and model what-if scenarios in the quoting stage. The application tracks production and inventory in real time with a graphical job-scheduling interface, resource-capacity planner and production/consumption check reports. Packaging managers also can choose to view all inventory and production lines with every unit produced adjusting the inventory instantaneously.

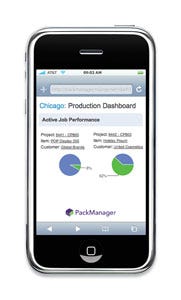

At PACK EXPO International 2008, Nulogy formally introduced the capability to access real-time packaging information from an iPhone or iPod Touch. As a web application, PackManager has always been available on mobile devices such as Apple's iPhone or Research in Motion's BlackBerry. The company's recent announcement pertains to PackManager Zero's compliance with the Safari browser that is used on an iPhone or iPod Touch devices.

As a Safari-compliant application, PackManager Zero now is designed to run as smoothly on the iPhone as on a desktop PC, and it takes full advantage of the devices' multi-touch navigating capabilities.

|

Nulogy CEO Jason Tham demonstrates how the company's now-Safari-compliant web application works on an iPhone. |

Nulogy reports that at least one of its customers has purchased iPhone hardware specifically to access packaging line data in real time.

Packaging-line data includes real-time monitoring of all packaging lines, captured reconciliation of rejected units, and machine downtime. It also offers full work-in-progress inventory visibility. For when production doesn't go exactly as planned, there is an application dashboard that offers expected versus actual metrics.

Packaging managers can use the SaaS application to calculate required materials and immediately adjust the production calendar. A graphical user interface allows managers to quickly schedule jobs using click-and-drag motions or their multi-touch equivalents.

In addition to the ability to track more than 50 business metrics, PackManager Zero allows packaging managers to create their own customized reports using the application, automate invoice generation and provide a customer portal for clients that require more production visibility from their contract packagers. For operations that need Excel compatibility, PackManager Zero also can to export reports in Excel format.

“It gives us the tools we need now to become more efficient to find our problem areas and overall have robust continuous improvement process in place,” says Wozniak. “It's part of how we are contending with the fact that costs are going up, and the market is becoming more competitive. It's impossible to increase our prices, even though our costs are going up.”

The program itself is designed to offer a quick return on investment. Based on the cost of $20/hr to manage the same information, Tham estimates a six-month ROI for most contract packaging companies.

Ease of implementation

While it's evident that QPSI employees hold a high level of technological prowess, QPSI does credit Nulogy's support with the ease of implementation. At presstime, QPSI implemented the cost-accounting piece at facilities in Mechanicsburg and Moonachie. At these locations, the software is being used by estimators and project coordinators.

The software company provided two, one-week training sessions on the system from an estimation and production standpoint. Every Friday, QPSI and Nulogy employees meet to talk about any issues with the software and anything that QPSI would like to see integrated into the system. It's also an opportunity for QPSI to share lessons learned from the previous week.

Both standard and custom

Ongoing opportunities to improve the software is probably the strongest benefit associated with SaaS software. Because the application is being served via the World Wide Web, it can be continuously improved.

Nulogy takes advantage of this capability by rolling out updates on a monthly basis—if not sooner. Nulogy chief technology officer Kevin Wong says the company gathers ideas for improvements from customers and observations of contract packaging as a whole. These ideas are integrated into a product road map, which has served Nulogy well. “So when a particular customization request comes from someone, we basically look at it and see if it fits into the road map already,” says Wong. “Frequently, this is the case.”

When true customization is required, Nulogy goes through a more thorough request-for-features process that allows them to engineer something specific to that contract packager's operations.

Nulogy is working on an application program interface(API) that will allow third-party applications to pull from or interact with the SaaS software. These modules will offer a standardized way for contract packagers to build their own modules and still take advantage of the strengths of the standardized PackManager Zero software.

More information is available: |

Nulogy, 888/685-6491. www.nulogy.com. |

About the Author(s)

You May Also Like