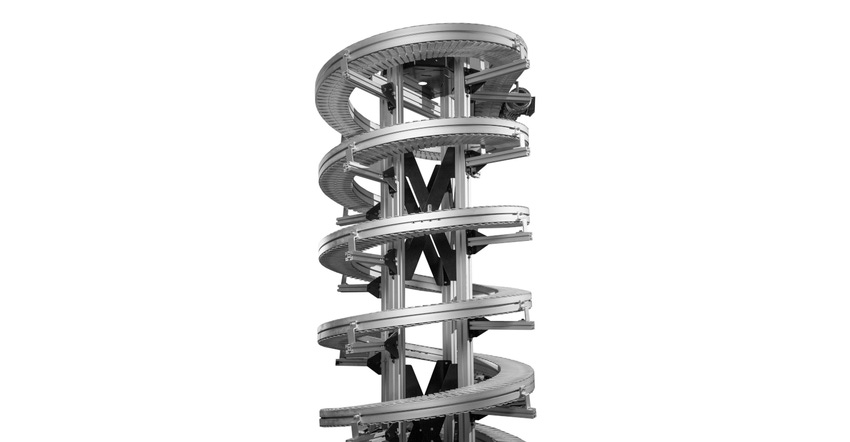

Dorner’s new conveyor option lets manufacturing engineers gets creative with line layout when plant space is limited.

A new tight turning-radius option for Dorner FlexMove Helix Conveyors offers packagers greater flexibility when laying out production lines, for applications such as accumulation, buffering, and product cooling. The conveyor’s small footprint also addresses the problem of tight line space.

Compact turns, with a diameter of spiral measuring 1,000 millimeters (39.4 inches) at centerline, are possible with the tight turning-radius option. The option is available on DTools, Dorner’s online conveyor configuration tool.

Featuring a reinforced frame structure for strength and durability, Helix Conveyors can be set at an incline angle of up to 7 degrees with a flat-top chain, and up to 10 deg with a friction-top chain. The conveyors offer speeds up to 52 meters/minute (171 ft/min), and they can accommodate loads up to 136 kilograms (300 pounds). All Helix Conveyors are built to order and delivered in about 30 days.

About the Author(s)

You May Also Like