March 11, 2015

Source: InTech magazine, May/June 2011. Copyright © 2011 ISA. Reprinted by permission. All rights reserved.

By Thomas R. Neuberger

Our collective demand for power continues to grow and is projected to double in the next 20 years. At the same time, businesses continue to seek solutions that deliver improved energy efficiency and system reliability and extend the life of valuable assets. There is a range of new and traditional solutions able to help businesses manage their power consumption more sustainably-reducing energy utilization while improving the bottom line.

For more than 40 years, variable frequency drives (VFDs) have been a critical component of commercial and industrial systems' efforts to improve energy efficiency. Today, their fundamental usage has remained the same, while technology has evolved and improved-yielding drives that are better able than ever to reduce energy consumption and improve reliability while extending equipment life.

Drives defined

Drives were originally designed to simplify industrial control processes. By electronically controlling the power supplied to a motor, they provide a way to control motor speed. They replaced mechanical means, which involved gears and clutches to enable multiple speeds, valves to reduce flow rates, and louvers to vent excess airflow. The reduction of mechanical means throughout a facility reduced the need for additional maintenance.

Fundamentally, VFDs are designed for applications that require variable power output and precise speed control. They are able to adjust a motor's speed to closely match its requirements. In other words, they help you use the energy you need and no more.

Comparatively, typical across-the-line starting utilizes 100% of the motor's power at all times. Yet, operating at 100% power is not necessarily required, so mechanical methods were used to vary the system output. But they did not control the actual motor output or, more importantly, the power consumed by the motor. Restrictive devices waste energy and increase costs. They are as efficient as driving a car with the gas pedal to the floor and controlling the speed by pressing the brake.

By reducing the input power to the motor, VFDs result in energy savings from 10 to 50%. Beyond energy savings, VFDs help protect assets and extend equipment life by reducing the mechanical and electrical stresses created by full-voltage or across-the-line starting and can incorporate functionality typically found in programmable logic controllers (PLCs).

How do VFDs work?

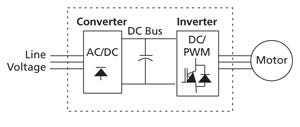

To better understand the advantages VFDs can provide facilities and processes, it is important to understand how they function. Drives consist of four main sections-a direct current (DC) rectifier, DC bus, inverter, and a microprocessor. Typically, three-phase, 60 hertz (Hz) or a single-phase source of alternating current (AC) power is fed to the input of the VFD, which consists of an AC to DC rectifier.

Generally, the rectifier utilizes six diodes to convert the AC voltage at a fixed frequency to a DC voltage, which is stored on the DC bus. In turn, the DC bus consists of capacitors used to regulate and maintain a consistent DC voltage and feed the inverter section of the drive. The inverter section utilizes Insulated Gate Bipolar Transistors (IGBTs) to convert the DC bus voltage into pulses, simulating an AC sine wave.

The output frequency and voltage is adjusted by varying the duration of each IGBT pulse; this is where the term Pulse Width Modulation (PWM) comes from. Finall

isa1.jpg

y, the microprocessor (not shown in the diagram) interprets user commands through a keypad, input/output (I/O) terminals, or communication protocols and regulates the modulation of the IGBTs. This is a simplistic diagram example of an AC VFD:What do they do?

Drives enable users to adjust the speed of motors without additional mechanical means. VFDs are also capable of providing a constant torque or maintaining a consistent speed, while the loads may change. An escalator is a great example of this feature. The escalator maintains a constant speed regardless if one person or 20 people are riding at the same time. VFDs are able to monitor the load and adjust their output to maintain the speed. They also incorporate simple PLC-like functionality into one unit. Digital and analog I/Os are common on VFD platforms.

VFDs help to reduce the mechanical and electrical stresses on the facilities infrastructure. Across-the-line starting can create large instantaneous torsion, friction, and tension strains on motor shafts, linkages, belts, and couplers. The instantaneous and repetitive stress can lead to premature failure of these devices. Further, it can draw an excessive amount of current, up to 12 times the motor's full load amps (FLA) depending on the NEMA type of motor being used. Typical NEMA-style B squirrel cage induction motors will draw up to six or seven times the motors FLA.

The inrush of current on larger loads can drain a facility's electrical capacity and create numerous problems, including contactor dropouts, diminishing lights, and disruption to IT networks. In addition, electrical utilities charge facilities based on peak demand usage. Large inrush currents or multiple motors starting at once can easily exceed a facilities capacity and lead to excessive peak demand charges. Furthermore, a VFD operates on the linear slope of the torque/speed curve of the motor during starting by matching the electrical and mechanical frequency of the motor. This produces more torque per amp than an across-the-line starter, thus maximizing the power being used.

isa2.jpg

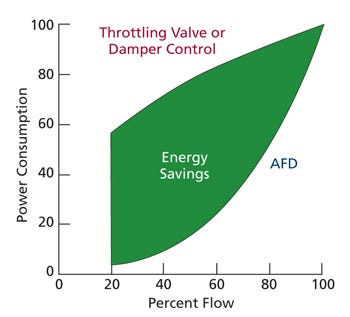

Without a VFD, motors are run continually at 100%, and speed is adjusted by mechanical methods. A VFD allows you to decrease the power output to regulate the speed and avoid energy waste. Energy savings are also available in fan and pump applications. There are notable power consumption differences between standard mechanical flow control methods (valves or damper controls) vs. VFD power consumption.

For example, if an 80% flow rate is required, approximately 90% power is consumed when using standard mechanical means to control flow. On the other hand, if you utilized a VFD to maintain that same 80% flow rate, you can decrease your power consumption to approximately 45%. This equates to a 40 to 50% savings over traditional methods. The savings is even more impressive when you drop the flow rates even further. At a flow rate of 40%, users would realize a power consumption savings of approximately 60%.

For years, VFDs have been relied upon to simplify process control, reduce mechanical and electrical stresses, and dramatically decrease power consumption. Today, VFDs are more efficient, accurate, and robust-leading to improved energy efficiency. Enhancements in capacitors, IGBTs, heat management, processing power, and measuring technology are continually improving the efficiency of drives to reduce motor losses and save energy-further decreasing electricity bills.

ABOUT THE AUTHOR - Thomas R. Neuberger ([email protected]) is a product manager at Eaton.

About the Author(s)

You May Also Like