March 11, 2015

Advanced Electron Beams (AEB), a leading provider of electron beam technology, announced a strategic partnership with Hitachi Zosen Corp. to develop the first aseptic bottle filling system that uses AEB's e16ITB emitter for "in the bottle" sterilization of PET and HDPE bottles.

The eITB Series emitters bring AEB's proven sterilization technology, already in use for Form, Fill and Seal packaging applications, to aseptic bottle filling. Surfaces of packaging materials are sterilized at high speeds with a stream of energetic electrons using far less energy and without chemicals and water - eliminating the risk of residual chemicals.

"Japan leads the global conversion to chemical free bottle sterilization. With this new product, Hitachi Zosen takes the leadership position among suppliers of chemical free bottle filling systems," said Brian Philips, vice president of sales, AEB. "This new product allows Japanese bottlers to set the bar for sustainable and chemical-free bottling worldwide."

Introduced in March 2011 and designed specifically for the Asian bottling market, the e16ITB accommodates bottle geometries that require a narrow nozzle emitter. Based on the new emitter, Hitachi Zosen has developed an electron beam sterilization machine for 500ml beverage PET bottle filling at a speed of 600 bpm (bottles per minute).

According to Hitachi Zosen, the electron beam-based system will offer significant improvements over traditional sterilization systems, specifically by eliminating liquid chemical costs and enabling lighter weight bottles, which will result in cost reductions up to 100 million yen per year.

Why Electron Beam Sterilization

Electron beam sterilization - a chemical free, ambient temperature sterilization process - addresses the concerns associated with aseptic beverage filling processes that traditionally require liquid chemical sterilants and heavier weight bottles. Electron beam, being chemical free, eliminates chemical residuals, production rinse water, water treatment and the logistics of chemical supply. Electron beam, being an ambient temperature process, enables maximum light-weighting of the bottle enabling significant savings.

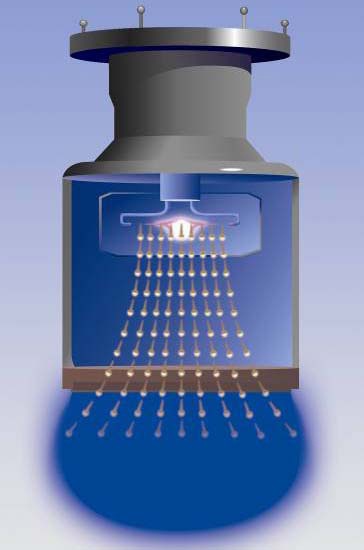

Derived from AEB's e25ITB emitter platform, the e16ITB emitter features a 16mm diameter, 350mm length nozzle compatible with narrow neck bottles up to two liters in volume. The e16ITB emitter can sterilize a single serve bottle in approximately two seconds, thus supporting typical high-speed aseptic filling systems.

The move to electron beam from traditional sterilization technologies is growing due to the rising cost of energy and bottle resin, and the increasing pressure to reduce waste and chemical use. With AEB's eITB Series emitters, brand owners and co-packers in the beverage bottle market can realize significant cost savings by reducing energy use and bottle resin, while eliminating the use of chemicals and water in their aseptic bottling systems.

Resin reductions decrease overall bottle weight resulting in annual cost savings of $392,000 per gram on a typical 600BPM line. (See http://plasticsnews.com/resin-pricing/commodity-tps.html). Electron beam-based bottle sterilization offers the lowest cost of ownership and smallest footprint compared to traditional chemical-based sterilization systems.

About the Author(s)

You May Also Like