Preci-Manufacturing Inc., Winooski, VT, manufactures precision mechanical components for the aerospace, defense, injection molding, opto-elec

Preci-Manufacturing_Operator8-10.jpg

tronics and medical instrumentation markets. The company specializes in rotating components made from high-temperature metal alloys, such as Inconel and Waspaloy. Products are generally packaged one item per bag.

Preci-Manufacturing primarily serves Fortune 500 companies and can have more than 400 jobs in house at any one time. Much of those companies' work is for the U.S. military, which requires that components be packaged in waterproof, greaseproof kraft paper bags. This was a very labor-intensive packaging process that required opening the bag by hand, inserting the product, closing and sealing the bag and affixing a printed label on the outside.

When Automated Packaging Systems introduced MLT1 and MLT2 films, it opened the door for a new type of bag packaging that yields tremendous improvements in productivity. MLT1 and MLT2 are plastic bag materials that meet Mil Spec DTL-117H, Type II, Class C, Style 1 or 2, which is the classification for a waterproof and greaseproof bag. These nine-layer, coextruded films have excellent barrier properties, are extremely strong and are ideal for waterproof and greaseproof applications. The bags, which are supplied on rolls for easy handling, meet specific military requirements for superior strength and durability and feature high-integrity side seals that ensure long-lasting containment of oily and damp products. The MLT1 film is opaque and MLT2 film is clear. Both materials are 4 mils thick and support printing and imprinting directly on the bag. A built-in sealant layer facilitates high quality seals.

Bag packing system includes an integral thermal printer

Lloyd Grunvald, vp of manufacturing at Preci-Manufacturing, had seen the Autobag bagging systems at trade shows and was interested in that kind of speed and efficiency for his operation, but the U.S. military required the special kraft paper for its packaging. As soon as he learned that Automated Packaging Systems' new plastic bag-on-a-roll material met the necessary Mil Spec requirements for waterproof, greaseproof bags, he knew he could reduce costs and improve productivity with an automated solution.

Preci-Manufacturing selected an Autobag AB 180 high-speed, automated bag packaging system with integrated PI 412c thermal transfer imprinter. The Autobag AB 180 is capable of packaging up to 80 bags/min and changeovers between jobs takes less than two minutes. A powered bag unwind system provides positive web control that minimizes bag movement for accurate positioning and loading and for in-line printing accuracy. The color AutoTouch control screen interface offers operator tutorials, data storage, a help system, diagnostics and performance monitoring such as production rates/job and bags/min.

When used in conjunction with the AB 180 bagging system, the Pl412c printer can apply virtually all barcodes including 2D styles to individual packages. Label changes can be achieved in an instant by simply accessing pre-stored label designs or through database downloads with a PC connection.

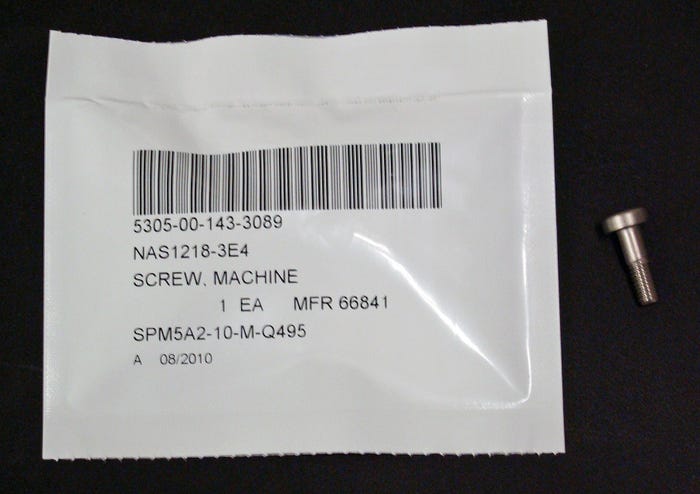

Preci-Manufacturing now packages its components in the plastic polybags and use the inline printer to print part number, quantity, date, NSN (National Stock Number), bar code and more directly onto the bag, eliminating the need for separate labels. Industrial components are packaged with standard Autobag material, while military components are packaged with Autobag MLT materials.

Operator loads bags

The company uses the Autobag AB 180 bagger as a semi-automatic system with one operator hand loading the product into a pre-opened bag that is automatically positioned for easy insertion and then automatically sealed and dropped into a bin for distribution. The bags are printed inline with the proper bar code and product information, eliminating the need for a separate label.

Grunvald says, "We would need three to four additi

Preci Manufacturing Sealed Bag and Part 8-10.jpg

onal people if we didn't have the Autobag bagger. A 20,000 piece job would take us two weeks to package before, and now we can have that done in two days."Preci-Manufacturing typically has one full-time person operating the Autobag system to keep up with demand. Most products are packaged in 3x3.5 in. or 4x6 in. bags.

All bag packaging criteria, including printing specs, are stored in the system memory and called up by part number using the operator-friendly AutoTouch control screen.

Benefits of the Autobag system include increased productivity, reduced costs, fast changeover between runs and ease of use.

Automated Packaging Systems Inc., 800-527-0733. www.autobag.com

About the Author(s)

You May Also Like