Overhill Farms Inc. is a leading valu

O-leaving Adco1.jpg

e-added contract supplier of custom, high quality prepared frozen foods for branded retail, private label, food service and airline customers.

Its product line includes entrées, plated meals, bulk-packed meal components, pastas, soups, sauces, poultry, meat and fish specialties, as well as organic and vegetarian offerings.

Its customers include prominent nationally recognized names such as Jenny Craig Inc., Safeway Inc., Panda Restaurant Group Inc., Pinnacle Foods Group LLC and American Airlines Inc. In August, 2011, Overhill Farms Inc. launched the Boston Market frozen food line.

Certified to meet

international standard

In 2010, Overhill Farms' food safety systems were certified as meeting the standards of the Food Safety System Certification standard, formally known as FSSC 22000:2010.

"We are extremely proud to be the first recipient of this globally recognized certification in our industry," says James Rudis, chairman and CEO of Overhill Farms. "It underscores the continuing commitment of all of our people to quality and safety throughout our manufacturing process."

This standard was developed by the nonprofit Foundation for Food Safety Certification, based in the Netherlands, and is based on the integration of the ISO 22000:2005 Food Safety Management Systems standard, used worldwide, and Publicly Available Specification (PAS) 220, issued by the British Standard Institution.

FSSC 22000: 2010 is supported by the Confederation of the Food and Drink Industries of the European Union. It has been recognized by the Global Food Safety Initiative (GFSI), which was established by The Consumer Goods Forum to pursue continuous improvement in food safety management systems, cost efficiency in the supply chain and safe food for consumers worldwide.

Single-serve entrees at 125 trays/min

Overh

O-Serpa1.jpg

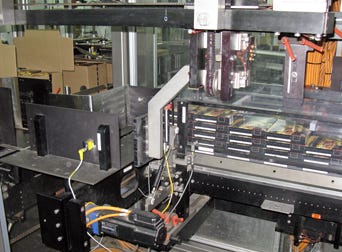

ill Farm's plant in Vernon Hills, CA has six packaging lines producing up to 7,000 cases of frozen products per day. Processing and tray filling takes place on the first floor, after which the products travel through spiral freezers and discharge to the end-of-line packaging operations, which take place on the second floor. The newest line at the plant was running single-serve entrées during Packaging Digest's visit.

The entrees exit the spiral freezer at a rate of 125/min and are transferred to a single file conveyor that transports them through a Safeline check weigher from Mettler Toledo Safeline. The cartons then drop into flights on the infeed conveyor to a Model 12BCS-200 multi-axis, servo-driven cartoner from Adco Manufacturing Inc.

Flat, end-loading cartons are placed into a 4-ft-long powered hopper that delivers them to a rotating, three-head carton feeder. Vacuum cups on each of the three heads pick cartons from the face of the magazine and erect them as they are placed into the carton conveyor, where the flaps are captured. The c

O-leaving Serpa1.jpg

arton conveyor runs parallel to the product conveyor, and an automatic barrel-cam inserter pushes the trays into the cartons as the trays and cartons travel through the cartoner.

The machine is equipped with no-product/no-carton and no-carton/no-product sensors. Thus, if a flight on the product conveyor is empty, a carton will not be erected in the corresponding flight on the carton conveyor. Conversely, if a carton is missing, the corresponding inserter will not move, and the product travels to the end of the conveyor and falls into a tub. The cartoner is also equipped with an adjustable-overload sensor system with an automatic retraction feature. If a tray jams as it is being pushed into the carton, the sensor detects the stoppage and retracts the pusher and stops the machine, so the operator can remove the jam.

The machine incorporates servo drives for the tray and carton conveyors, the carton opening system, flap tuckers and the tray loading system.

The end flaps of the filled cartons are glued by a ProBlue 7 hot-melt glue system from Nordson Corp., after which they pass a Thermal Scientific Apex 500 metal detector followed by a Videojet Technologies Inc. Excel ink-jet printer that applies a lot code and a use-by date to the bottom end-flap.

Pack two stacks of cartons at a time

The cartons then travel to a wrap-around case packer from Serpa Packaging Solutions. The wrap-around case blanks are in a magazine on the end of the machine and enter at right angles to the carton conveyor. The case erector pulls a case blank out of the magazine and erects it in the flight lugs.

The cartons enter the progressive upstacker at a right angle to the case packer and are assembled into 4-high stacks and two stacks at a time are pushed into the load area. A second 2-stack grouping is assembled and the stacks are then pushed through the load area and into the erected wrap-around case, which ultimately contains 16 cartons. The stacks are pu

O-metal1.jpg

shed through a telescoping funnel that partially enters the case to facilitate the loading of the cartons.

The loaded case is pushed through top rails that fold the horizontal and vertical sections of top flap down. The bottom end flaps are then folded up before the case is pushed at a right angle, and the final top flap is closed before case discharges from the machine. All of the flaps are sealed by a Nordson ProBlue 7 hot-melt glue system.

As a standard feature, sensors detect if cartons or cases are not present for loading. If cartons are not present, the erected case remains in place until cartons are available to be loaded. If a case is not present, the case packer indexes forward and a new case blank is picked and erected for the cartons to be loaded into.

Both the cartoner and case packer are equipped with controls and HMIs from Rockwell Automation.

The finished cases are hand palletized and the pallet loads are then stretch wrapped.

Overhill Farms Inc. launches Boston Market frozen food line Inc.

In August, 2011, Overhill Farms Inc. announced that it had entered into a sales, distribution, and co-manufacturing agreement with Bellisio Foods, Inc., in conjunction with the national launch by Overhill Farms of the Boston Market frozen food line.

In discussing the agreement with Bellisio, James Rudis, Chairman, President and Chief Executive Officer of Overhill Farms, says, "When Overhill Farms acquired the license to the Boston Market retail food line, we saw an opportunity for our companies to work together. Bellisio has an experienced sales and marketing organization with longstanding relationships with virtually all major retailers, mass merchandisers, club stores, convenience stores and the military.

They also efficiently distribute products to these major retailers and other outlets, which include all Boston Market customers. Utilizing these capabilities enables Overhill Farms to implement a smooth and cost-effective transition from the previous supplier of Boston Market frozen meals."

Rudis notes that, with the assistance of Bellisio's sales team, theOverhill Farms has been able to retain virtually all of the retailer accounts that had previously carried the Boston Market product.

Rudis says that the Bellisio agreement should result in lower costs to manufacture and distribute the Boston Market products. The Boston Market products can be combined with Bellisio products in full-truck shipments to the Boston Market customer base, which presently is heavily represented in the Eastern and Midwestern portions of the country. The agreement also enables Overhill Farms to avoid the cost and time needed to develop an equivalent sales and distribution system internally, he noted.

All Boston Market products, including those manufactured b

O-end.jpg

y Overhill Farms, will be warehoused and distributed by Bellisio through their facilities centrally located in Jackson, OH. Overhill Farms will be responsible for overall product quality and for development of new items for the Boston Market line.

The agreement calls for manufacturing, sales, warehousing and distribution to be provided by Bellisio at fixed costs, with Bellisio to receive a pre-determined portion of profits resulting from these sales. The term of the agreement is 24 months.

"We carefully reviewed the cost-effectiveness of this collaborative arrangement with Bellisio compared to Overhill Farms proceeding on a stand-alone basis," Rudis says. "Under this arrangement, the overall profitability of the Boston Market line should be significantly improved, which is in the best interests of the Company, our customers and our shareholders."

Rudis says Overhill Farms and Bellisio Foods will explore similar potential opportunities that can be to the companies' mutual advantage.

Adco Manufacturing Inc., 559-875-5563. www.adcomfg.com

Mettler Toledo Safeline, 800-447-4439. www.us.mt.com

Nordson Corp., 770-497-3700. www.nordson.com

Rockwell Automation, 414/382-2000. www.rockwellautomation.com

Serpa Packaging Solutions, 559-651-2339. www.serpapackaging.com

Thermo Scientific, 800-22-8891. www.thermoscientific.com

Videojet Technologies Inc., 800-843-3610. www.videojet.com

About the Author(s)

You May Also Like