March 11, 2015

|

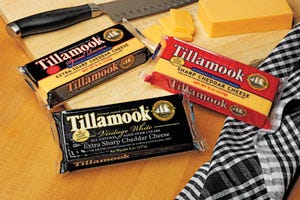

For nearly a century, Tillamook County Creamery Assn. (TCCA), Tillamook, OR, has delivered farm-fresh dairy products with all-natural ingredients—a combination that, along with the company's operations and community service, has resulted in numerous awards from industry publications and organizations. For customers, flavor is key, and it's all about TCCA's hands-on approach. "We age all our cheese in-house, including our medium cheddar, which is aged more than 60 days to ensure optimum flavor," says Tim Tomlinson, packaging manager for TCCA. "That ensures it's very high-quality."

Automated weighing system

TCCA is a farmer-owned cooperative that includes approximately 120 dairy families throughout the country. The co-op offers a variety of cheeses in a broad range of sizes—from 5-lb blocks to ¾-oz portions for on-the-go treats. Affirming that each of these products weighs the correct amount—in order to confirm correct product quantity and pricing— is an important part of the process.

"We have an automated system that weighs packages as they are transferred down a conveyor and directs the packages as needed, but we have to confirm that these weights are correct on a regular basis," Tomlinson says.

After a large block of cheese has been properly aged, a series of wires cuts it into smaller loaves. An in-line checkweigher then verifies that each loaf weighs the correct amount, within a defined tolerance before packaging. If a loaf is above or below this tolerance, a static checkweigher determines how far off the loaf is from the desired weight. "To meet weight standards and regulations, we use this static checkweigher to verify package weights about every 15 seconds," Tomlinson says. "For this, we needed to replace our previous stand-alone checkweigher with an upgraded selection."

Customized software

|

The stand-alone checkweigher’s display is highly visible and is customized for simple, efficient visual weight confirmation and/or corrections if needed. If the checkweigher finds that a loaf is underweight or overweight, it displays how much |

TCCA chose the E1310 programmable-weight indicator for checkweighing from Avery Weigh-Tronix

(www.wtxweb.com), which offers a stainless-steel construction and a National Electrical Mfg. Assn. (NEMA) 6/4X rating to withstand harsh washdown environments. "Stainless steel is necessary, since the equipment we use needs to be food-grade," Tomlinson says. "We've been happy with its accuracy."

The E1310 checkweigher provides National Type Evaluation Program (NTEP) Class III legal-for-trade weighing with sealed, stainless-steel loadcells and 500 percent overload protection. Its display is highly visible and is customized for simple, efficient visual weight confirmation and/or corrections if needed. If the E1310 checkweigher finds that a loaf is underweight or overweight, it displays how much cheese must be added or removed to meet weight requirements.

"The Avery Weigh-Tronix checkweigher sits on the side of our packaging line, so that we can manually check the calibration of our high-speed weighing operations," Tomlinson says. "And we can communicate recorded weights to our computers, so we can download all the collected data, which is really nice."

Customizable serial output

Along with accurate weighing, the E1310 checkweigher offers fully customizable serial output, including three outputs for controlling external devices. It additionally provides three inputs for remote print, pushbutton tare and other functions, offering TCCA the flexibility to upgrade its current processes for future applications.

"Right now, we're basically using it for visual confirmation of our package weights, but if we automate our backup weighing in the future as planned, we'll be using the checkweigher to its full capacity," Tomlinson says.

The rugged construction and reliable operation has made this checkweigher package an effective solution for TCCA, helping them produce and distribute premium-quality cheeses with local flavor efficiently and accurately. "We were looking for a good replacement, and the E1310 checkweigher is living up to it," Tomlinson says.

More information is available: |

Avery Weigh-Tronix, 507/238-4461. www.wtxweb.com. |

You May Also Like