Jelly Belly beauty shot

An automated packaging line in its North Chicago, IL, plant is helping Jelly Belly maintain a consistent, high-quality look for its new, eye-catching gift bag. Designed to appeal to adults and communicate the gourmet quality of the jelly beans inside, the shimmering stand-up pouch debuted this fall in a kaleidoscope of colors to complement the 10 year-round favorites and nine seasonal products in the line. Additional products are scheduled to roll out through 2013 into specialty, department and grocery stores nationwide.

The metallized pouch is replacing the company's previous European-style tie-top bag for specialty sales to modernize this business segment and create better shelf impact. According to John Pola, Jelly Belly's vp of specialty sales, the new package is typically bought as a gift, poured into candy dishes or shared by the customer with someone at home or in the office, so a reclosable feature wasn't necessary. "The vertical format displays well on the shelf and incorporates into gift baskets that are so popular among our specialty retailers," Pola says. "And the size hits the right price point at retail."

Jelly Belly's in-house team created the packaging graphics, designing the bags with a clear window on the front in the shape of a bean so consumers could see the gourmet products inside.

Supplied by Innovative Packaging Solutions Inc. (IPS), the film structure consists of an OPP layer-reverse printed in 10 colors on a rotogravure press-laminated to a PP-based sealant layer and metallized. The clear window is created through a separate demetallization process.

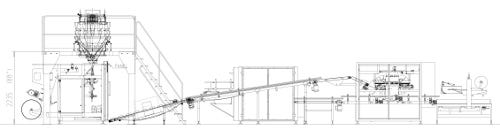

Jelly Belly VFFS

Decisions, decisionsJelly Belly installed an entire new packaging line in early July 2012 to produce the upscale bag in time for the fall selling season. It's a dedicated line—for now—running one size of a 4-side sealed pouch in volumes from 4.75 to 7.5 ounces, depending on the product inside.

Michael Bianco, svp, global operations and distribution—and a 28-year Jelly Belly employee, based in the Fairfield, CA, headquarters—says the company chose the North Chicago facility of its three manufacturing sites (North Chicago, Fairfield and Thailand) because that plant produces the company's full line of products, including the seasonal items earmarked for this package.

The company chose this particular packaging line because:

• It can produce the package format Jelly Belly wanted, which is a four-side sealed bag that sits upright on the shelf.

• It is highly automated and integrated, able to accommodate online printing (to minimize the preprinted film inventory) and promotional labeling.

• It is versatile, able to run different packages and products in the future, including gummies—"Whatever the market dictates," Bianco says.

• It is designed for sanitation, with all product-contact parts easy to remove and clean.

Jelly Belly worked with a company in Eastern Europe, Radpak Ltd. Engineering Co., to build and integrate the line. Radpak also supplied many of the systems, including the vertical form/fill/seal machine, the platform for the scale, the controls, conveyors and the case erector, packer and sealer. "We looked at lots of pieces of equipment from about six to eight companies," Bianco says. "After the dust settled, this particular line met our needs. And they were complete. Radpak did everything. This company was wonderful to work with."

Prior to selecting the line integrator, Jelly Belly's owner, Herman Rowland Sr., traveled to Poland to meet with Radpak. Rowland, who is technically oriented, made a few suggestions for improvements, which were incorporated into the final design.

Jelly Belly turret

For example, he designed a rotary turret at the base of the vertical form/fill/seal machine. The turret catches the bags and, as it indexes around, gives the seals just enough time to set and cool under the weight of the product before exiting on the takeaway conveyor. This compression for a couple seconds ensures that the bottom forms well enough for the pouch to stand up nicely on store shelves.

Rowland also asked and paid a bit more for a heavier stand to hold the combination scale above the VFFS system. This helps minimize vibration and keeps it from extending up and down the line to the other machines, which could shorten their life.

Jelly Belly case erector

The benefits of automation are multifold, starting with labor savings and worker safety. "This is a competitive world we live in. We need to watch our costs," Bianco says. "Radpak was able to provide us with a complete line so we don't have people doing repetitive motion." The line also makes it easier to produce a high-quality package and at the required output speed.

The entire line has integrated electronic controls, from product feeding through case packing, which are a mix of the Radpak standard Siemens and the Jelly Belly preferred Allen-Bradley from Rockwell Automation. "We do try to stick to that. Our people all know the Allen-Bradley logic and can deal with it," Bianco says. "Radpak worked to make this [integration] as simple as they could for us."

Filling a need

On the front end of the line, Jelly Belly is using a sophisticated product feeding system. The stainless steel belt, vibratory and bucket conveyors from Frazier & Son have a sanitary design. The feeding belt can be easily removed in five minutes without tools for cleaning. The sides pull down, the cap comes off at the end and the belt slides right out. Jelly Belly does a complete washdown after packaging any products with allergens.

The day of Packaging Digest's visit, the line was running its popular 49 Assorted Flavors jelly beans. Product is manually added to the feeder belt (this operation may be automated in the future). Level sensors in the vibratory pan control the product's infeed drop, as well as into a polycarbonate bucket elevator (also from Frazier & Son, whose systems are in all of Jelly Belly's plants).

The buckets take the candy up to a Yamato 14-head combination weigh scale. The scale buckets are also easy to remove for cleaning. With this scale, Jelly Belly can run gummies or virtually any product the company makes, including fragile products. With some change parts, the system can cut down the angle of the drop for gentler handling.

A common theme Bianco talks about is that Jelly Belly often chooses the same supplier for different projects. "We have mostly all Yamato scales, for example. You have operators, mechanics...if you have everything different, it's tough on them."

At the back of the VFFS machine, two Videojet Dataflex Plus 4x4 thermal transfer overprinters print on the front and/or back of pouches, as needed. Operators scan the product bar code from a book and the system automatically sets up. Again, Bianco explains that they use the same Videojet printers in all their factories. "It's easier to maintain, to have parts and, certainly, when you start messing around with electronics, computers and drivers, readers and everything else, you better have it all the same."

For about half of the products in this new package, the flavor name is printed on the front, as well as a lot code and "Best Before" date on the back. Top sellers, such as the assortment pack, are preprinted with the name and only the codes on back are printed online. Bianco says the amount of online printing causes no difference in line speed.

At the side of the VFFS, Jelly Belly installed a Flexpack pressure-sensitive labeler from EPI Labelers. This automatically applies price or other promotional labels to the pouches as needed instead of hand-placing stickers. Eliminating the manual labor by automating this task allows Jelly Belly to react to customer needs faster than before. Bianco estimates that they'll use the labeler about 25 percent of the time.

The continuous-motion VFFS system—a customized standard Radpak model VVF&S—controls the film all the way through the operation and produces 80 pouches/min. Tadeusz Radzanowski, president of Radpak, explains, "Jelly Belly visited us and we ran some tests on our standard bagger. In two days of tests and discussions, we developed the best solutions for performance and from a service point of view."

Bianco says a nice feature about this machine is it talks to the manufacturer in Poland via Ethernet for fast troubleshooting. "They can look at what the machine is doing there. When we have issues, they can advise. They can even correct some of the programming. It's pretty amazing," Bianco says.

Jelly Belly specified sealing jaws from its U.S. supplier, Lako Tool & Manufacturing. "Just for the sake of this machine being in the United States, and easier for us to deal with, we have a local supplier for jaws," Bianco says. "We use the same company for all our jaws and have had excellent success. Radpak had no issues with that because they buy jaws from other [sources] as well."

The bagger has the latest Siemens PLC model Simotion D435 multi servo control system with a Siemens 10-in. HMI. From the panel, one operator can control the bagger and the labeler. The system also has a motorized automatic film centering feature and automatic correction of film stretching.

As mentioned earlier, the servo-driven discharge turret gives the bag a few seconds to set its seals while the weight of the product provides adequate compression. "But when you're trying to cool down the film," Bianco explains, "what you're doing is forcing the memory, between temperature and time, to create the flat bottom."

As bags leave the rotary turret, they pass through a metal detector. The Mettler Toledo Safeline 200X HI50 metal detector is programmed to make allowances for the amount of metallization on the film. If it reads more than that, it kicks out the package.

Cases are erected and bottom sealed with pressure-sensitive tape. The system is adjustable, via an Allen-Bradley PLC, but it's set up to run just the one size for now.

Jelly Belly case packer

From the base of the filler, pouches convey up a slight incline to enter the collation station of the Radpak case packer, a top-load system with Racetrack model RGZ-100, and Allen-Bradley PLC and servo drives. The approximate 4-foot elevation from the filler exit to the case packer was necessary to hit the plant's standard height of the discharge conveyor. Pouches are packed into cases standing up in a 12-count. The laid-down pouches drop from the flat conveyor onto a slightly lower conveyor in a vertical position and are collated into two rows of six before being dropped into open cases below.

The weight of the bag here, unlike when it makes the short drop into the turret at the bottom of the VFFS and helps set up the base of the stand-up bag, could damage the product as it drops down into a waiting case. So cases are raised as bags gravity-fall to minimize the height of the drop.

From a hygienic point of view, Radzanowski says, "The machines were designed for easy cleaning with open frame design, clear doors, fully guarded with excellent view and frames made of tubes with clean welding."

See a video of the VFFS and case packing operations at www.packagingdigest.com/JellyBellyRadpak.

Cases pass over a Mettler Toledo Beltway XE checkweigher to ensure proper case count, and then are coded. Generic cases are preprinted, but product-specific info, count, weight and lot number are printed directly on cases online using a Marsh Encore inkjet system (now part of Videojet). Bianco says direct case coding is simpler and cheaper than using a print-and-apply label. Finished cases are then conveyed across the plant to be manually palletized.

"This came together pretty smoothly, both internally and externally, with all the different vendors. Our scale people, metal detector people, our labelers, our [printer] folks," Bianco says. "There was a lot of work involved but it went relatively smoothly."

Straight and simple

In putting together similar lines, Radpak normally uses a different configuration, but it built this one to suit Jelly Belly's needs. Bianco set up the operation in a straight line to keep it simple and eliminate any 90-degree turns.

"I'm a strong believer in straight lines. If you have the room, keep it straight. I don't like U-turns or L's or any of that. If you go straight, your belts are always straight. If you do an L, you need a 90. If you do a U, you need two 90s," Bianco says. "Keep it simple. In industrial engineering, the straighter, the better."

EPI Labelers, 717-235-8345. www.epilabelers.com

Frazier & Son, 800-365-5438. www.frazierandson.com

Innovative Packaging Solutions Inc. (IPS), 951-693-5580. www.ipspack.com

Lako Tool & Manufacturing Inc., 800-228-2982. www.lakotool.com

Mettler Toledo, 800-836-0836. http://us.mt.com

Radpak Ltd. Engineering Co., +48 54 412-55-00. www.radpak.net

Rockwell Automation, 414-382-2000. www.rockwellautomation.com

Safeline (Mettler Toledo), 813-889-9500. http://us.mt.com

Siemens, 800-743-6367. www.industry.usa.siemens.com

Videojet Technologies, 800-843-3610. www.videojet.com

Yamato Corp.-Dataweigh, 262-236-0000. www.YamatoAmericas.com

Jelly Belly line drawing

.

About the Author(s)

You May Also Like