March 11, 2015

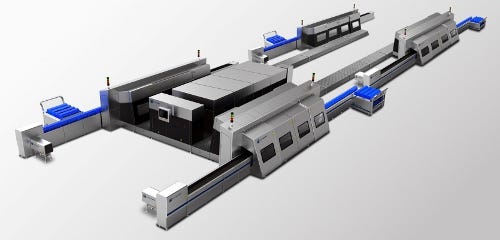

FresherTech Quattro

FresherTech North America has installed a high-pressure processing (HPP) system at a beverage producer in Austin, TX. The dual-chamber system is the first of its kind in North America.

FresherTech's ISO9001:2008 factory has been successfully building HPP systems for more than 11 years and is now entering the North American market.

The FresherTech system includes a number of innovations including multi-layer chambers, lightweight laminated steel frames and shared components in its multi-chamber systems. The system is modular, allowing customers to start with one chamber and easily add a second chamber as production increases. It is quieter, has lower maintenance costs and does not require expensive facility upgrades.

The capital cost of the FresherTech system is dramatically lower than the other systems on the market. FresherTech also aims to reduce the high maintenance costs common with other HPP systems. That effort is backed by a service plan for those companies that wish to limit their maintenance costs. FresherTech estimates that it will reduce total cost of ownership by up to 50 percent compared to its closest competitor.

The emphasis on service also extends beyond equipment support. FresherTech is backed by a $1 billion vertical food company with a large R&D staff and broad HPP experience to help customers make the transition to HPP.

Prospective customers will be given demonstrations of the new machine beginning in July. FresherTech will also have a booth at the upcoming Institute of Food Technologists show in Las Vegas, June 25-28.

Source: FresherTech North America

.

About the Author(s)

You May Also Like