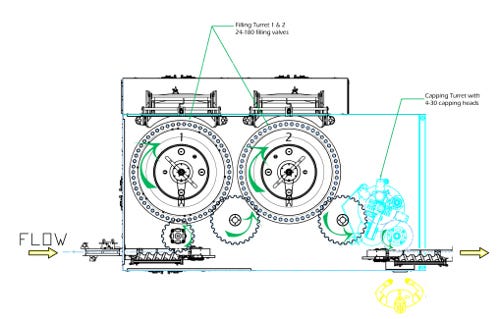

Twin filler bowls

Putting two filling bowls on one filler base with one capper allows for a lower initial investment, lower ceiling height requirements, smaller floor space requirements and more manageable maintenance. These twin bowls are smaller yet fill faster than one big filling bowl. This allows operations to use 100 percent of the capping capacity instead of wasting it by waiting for the fillers to fill. Two twin F6.2 filling bowls have a combined maximum capacity of 340 gallons. The twin bowl layout is about two feet narrower than a competitive single bowl machine layout and about four feet shorter. This will allow for a much more manageable installation into an existing plant that has lots of piping, wiring, elevated walkways and other height restrictions.

Fogg Filler, 616-786-FOGG (3644), www.foggfiller.com

.

About the Author(s)

You May Also Like