March 11, 2015

Variety Pack Solution

What it is...

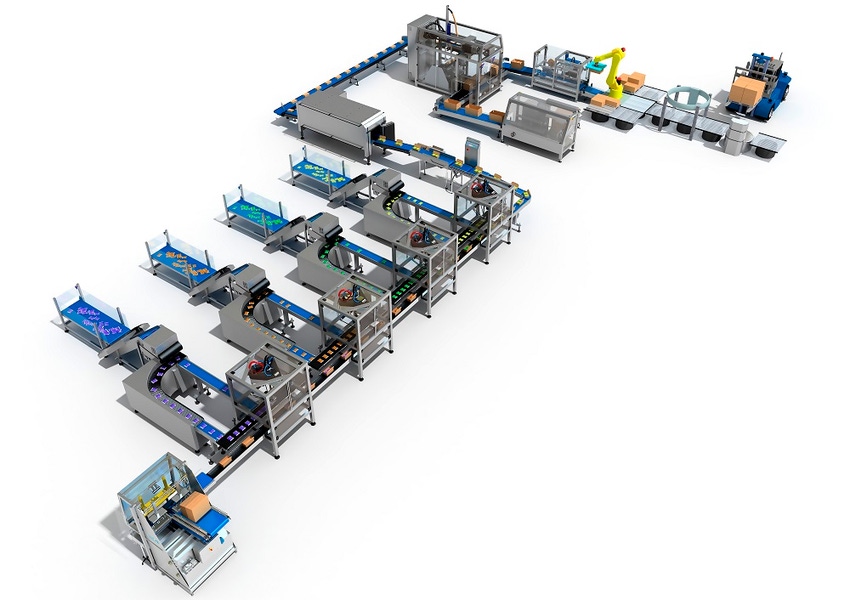

By utilizing a variety of our robot types, BluePrint Automation can build a turnkey varietypack solution, handling your product from the end of processing through palletizing.

How it works…

Varying flavors/styles of product are fed to our vision-guided robots from bulk feeding systems. Our vision-guided robots are an overhead supported, three or four axis robot, with a large working envelope. Product enters the working envelope via multiple product in-feeds (one per flavor/style). After being detected and quality inspected by a highly accurate vision system, the robot takes the input from the camera, goes directly to the product and re-orientates the product while placing each variety in the container specified!

A complete variety pack is then sealed and case-packed using one of our robotic case-packing systems. The cartons/trays are collated and picked by a specially designed end-effector, ensuring smooth placement into the secondary container.

A complete turnkey solution is achieved by including:

Product Inspection, Product Settling, Product Handling, Case Erecting/Closing, Case Inspection, Palletizing and/or Stretch-Wrapping

The benefits…

Expandable for any product count/configuration

Flexible: Loads unbalanced product counts

Dynamic loading of product into display trays

High efficiency and throughput

Accepts product from bulk using proprietary BluePrint Automation feeding technology

You May Also Like