What do a cobotic case loader, a low-volume capper and a compact labeler have in common? They all offer beverage packaging engineers new production options. And you can see all three of these new systems at Drinktec 2017.

If you’re in the beverage or liquid food markets, chances are good that you’ll be going to Munich, Germany, this September to see the newest technologies shown at Drinktec 2017 (Sept. 11-15), an event that happens just once every four years. Nearly a quarter of event visitors work in the manufacturing end of the business, which includes packaging. So more than 400 of the 1,700 exhibitors expected—also nearly 25%—will bring packaging innovations in equipment, as well as containers and materials.

Page 1. Cobotic case loader from Gebo Cermex.

Page 2. New capper from Silgan.

Page 3. Compact labeler, and compact can filler for craft breweries, from KHS.

Cobotic case loader safely takes on tedious tasks

The bending, lifting and twisting motions of packaging line workers filling a case erector magazine are not only tedious, but they can cause painful and costly musculoskeletal injuries. Adding a robotic loader to replenish case blanks into the feeding magazine can prevent these issues, but it requires extra floorspace for physical barriers for safety.

Now, a collaborative robot version of the automatic FlexiLoad magazine loader performs the same loading operation without the need for cumbersome guarding. The FlexiLoad cobot senses the presence of a person and either slows or stops depending on the proximity.

The new cobot loader can handle regular slotted containers (RSC), wraparound blanks and trays.

Gebo Cermex, Drinktec Booth #A6.330

NEXT: Slow and steady capper considers cleanliness needs

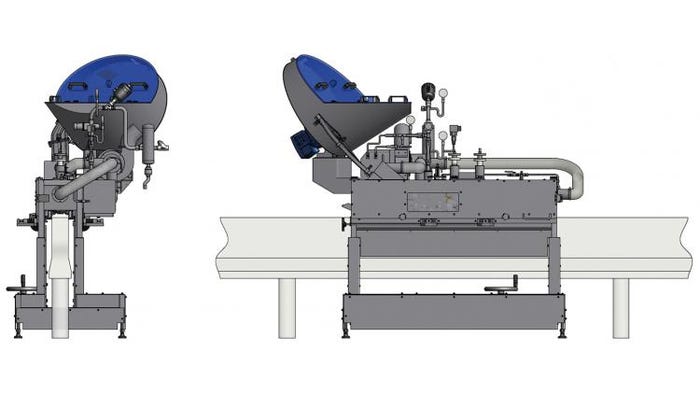

Slow and steady capper considers cleanliness needs

Not every beverage operation needs to run at full tilt. The new SWC 150 capper from Silgan was designed for lower speeds—around 100 to 150 containers per minute. The hygienic stainless steel machine is also CE compliant. It handles a variety of continuous-thread closure diameters, from 38 to 82mm.

Silgan, Drinktec Booth #A4.531

NEXT: Compact labeler targets craft brewers and bottlers

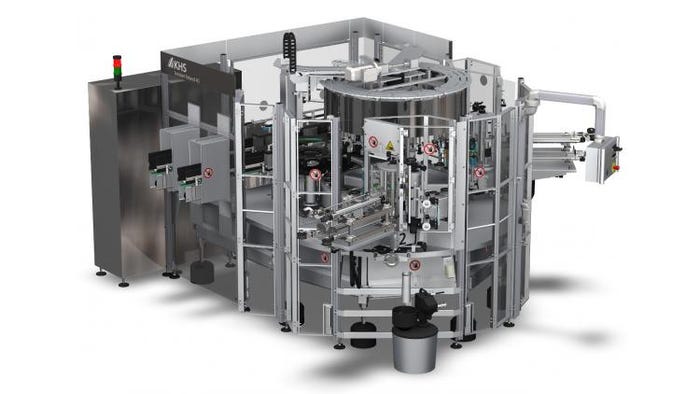

Compact labeler targets craft brewers and bottlers

Designed for simple operation that is still flexible enough to handle a range of containers and labels, the new Innoket Roland 40 labeler addresses the needs of craft breweries and spirits bottlers. The compact system can start small and expand as needed—with a capacity of 40 to 400+ bottles per minute.

The Innoket Roland 40 uses many of the same high-quality, proven components from its big brother, the high-capacity Innoket Neo labeler. It comes standard with two label stations: cold-glue, hot melt or pressure-sensitive, or a combination of technologies.

KHS, Drinktec Booth #B4.328

About the Author(s)

You May Also Like