Beverage Packaging

FB-Stream-GettyImages-ProStock-1305346806-1540x800.png

Food & Beverage

Best in New Food and Beverage PackagingBest in New Food and Beverage Packaging

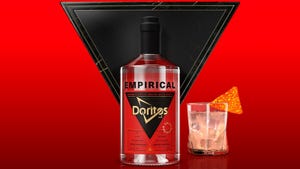

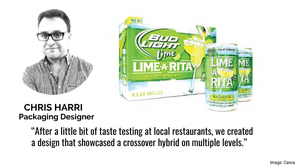

Compostable foodservice packaging, bottled Skittles, edible beeswax snack wrap, traceability tech for food, Biscoff cookie packs redesigned, Jamie Foxx whiskey.

Sign up for the Packaging Digest News & Insights newsletter.