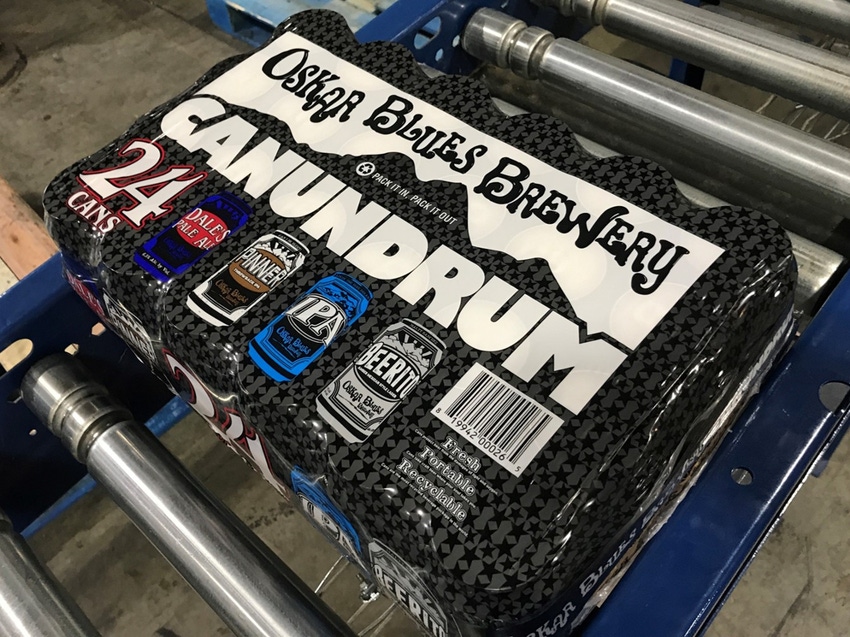

Oskar Blues Brewery, a member of CANarchy Craft Brewery Collective, has developed a sustainable packaging solution for its large-format variety packs that decreases the brewery’s environmental footprint, reduces packaging costs and creates a brand billboard at retail.

The beverage packaging design uses collation shrink film to wrap corrugated trays filled with two dozen cans—eliminating the paperboard previously used when dual 12-pack cartons were shrink wrapped.

Oskar Blues started using the new packaging in 2017, and the sustainability and business benefits have been substantial. “We were looking for a new packaging solution for 24-packs of cans that would reduce costs, rebrand our mixed cases, improve sustainability and differentiate our product offering to make it more appealing to retail outlets,” says Jeremy Rudolf, operations manager at CANarchy Craft Brewery Collective.

“To date, we’ve seen a 40% cost savings, 64% reduction in secondary packaging materials usage and 73% fewer trucks delivering packaging materials to Oskar Blues,” he adds. “We also expect to see 46% energy savings and 51% greenhouse gas emissions reduction, based on an environmental-impact assessment by Allied Development.”

The multipack packaging suppliers are Dow Packaging and Specialty Plastics (a unit of The Dow Chemical Co.), Berry Global and Ampacet. Dow supplies the resin, which Berry converts into shrink film; Ampacet provides color masterbatch technology used in printing. Oskar Blues uses a KHS Kisters 601T Registered Shrink Tunnel to run the multipacks.

*******************************************************************************

Production efficiencies, ecommerce challenges, sustainability trends, new bioplastic technologies and more are among the topics on the agenda at the new Packaging Education Hub at EastPack 2018 (June 12-14; NYC). This free educational program will have more than 15 hours of can’t-miss presentations, demonstrations and hands-on activities. Register to attend for free today!

*******************************************************************************

Rudolf and Ritika Kalia, end-use marketing manager at Dow Packaging and Specialty Plastics, answer a few questions about the project.

What capital-equipment investment did Oskar Blues make for this new multipack?

Rudolf: Conveyance, a used shrink tunnel and electrical installation was roughly $75,000.

What other packaging-line adjustments were need to run this pack?

Rudolf: Oskar Blues is currently packaging this large-format shrink package offline in its facility, with an added labor element consistent with other multipack solutions. As the package gains distribution and volume, Oskar Blues will look at integrating it in-line with other automated packaging processes.

Is there a perforation anywhere to make it easy for consumers to open the package?

Rudolf: There is no perforation on the package. The finished package can be opened quite easily without perforation or tools.

Is there a handle?

Kalia: Consumers can easily carry the case using the bull’s-eyes on each side of the package. The shrink wrap is strong enough to accommodate being carried like this and maintain packaging integrity without significant stretching or weakening.

Can the multipack be stored in a refrigerator?

Kalia: The properties of the shrink-wrap packaging make it perfectly suitable to store it intact within a refrigerator or cooler. The integrity of the package will remain in a typical range of conditions that cases would experience during transportation, storage and consumer handling.

Can retailers display the multipack vertically?

Kalia: The printed shrink-wrap packaging maintains integrity and shelf appeal displayed horizontally and vertically.

What Oskar Blues stock-keeping units (SKUs) will use the shrink-wrapped multipack?

Rudolf: Oskar Blues is currently using shrink film on its large-format, multipack SKU. This was a direct response to requests of retailers to have a large-format, single-branded surface that can communicate effectively with consumers. As this package continues to grow, Oskar Blues is looking for additional opportunities with film in all formats and package sizes.

Is the package an industry first?

Kalia: The Oskar Blues printed, shrink-wrapped mixed cases are a first for the U.S. craft beer industry. Other arrangements, including four-packs in similar packaging, are becoming common in North America. Printed, shrink-wrapped cases are already common in some geographies, including Europe and Latin America.

What is the significance of being first with this type of multipack?

Rudolf: Oskar Blues has always been an innovative leader in the U.S. craft beer industry, notably as the first American craft beer in a can, with Dale’s Pale Ale in 2002. This new secondary, shrink-wrap packaging continues that mission to differentiate our product and gain access to additional markets. And being first has put us in the spotlight—since piloting the packaging in 2017, we’ve seen more than 300% growth through national retailers.

About the Author(s)

You May Also Like