January 30, 2014

In 2010, European packages containing pharmaceuticals must have Braille embossing to identify the contents. This mandate is spurring other countries and pharmaceutical companies to adopt technologies which add Braille to their consumer packages.

The number of people that can be categorized as blind or partially sighted increases each year, mainly as a result of the higher life expectancy and aging of the population. Most of the visual disabilities manifest themselves at an older age, namely 88% after the age of 60 compared to 10% between 16 and 59 years and 2% below the age of 16 years. But unfortunately – less than 2% of the partially sighted and the blind can read Braille.

The number of people that can be categorized as blind or partially sighted increases each year, mainly as a result of the higher life expectancy and aging of the population. Most of the visual disabilities manifest themselves at an older age, namely 88% after the age of 60 compared to 10% between 16 and 59 years and 2% below the age of 16 years. But unfortunately – less than 2% of the partially sighted and the blind can read Braille.

But whether they can read it or not, the EU-directive represents a tremendous challenge to the pharmaceutical industry, as past experience has shown that it is often difficult or sometimes impossible to free sufficient room for the Braille characters on the label or packaging.

In order to help drug manufacturers to comply with the European legislation, several companies have developed their own unique solution. Among others Sleever introduced its Braille shrink-sleeve, CCL its BrailleMarker, Bobst its AccuBraille system and Nordson its e.dot.

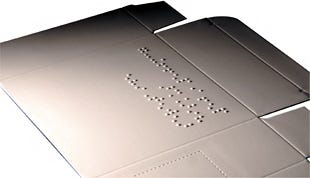

Recently Roberts PolyPro, a division of Pro Mach, a provider of integrated packaging products, introduced the Rapid Braille Module, a carton feeding/rotary Braille embossing system compatible with all folding-gluing machines. The Rapid Braille Module runs at speeds up to 1,500 feet (457.2 meters) per minute. Changeover of Braille embossing plates takes only minutes. The accuracy of the embossing process is +/- 1/16 inch (1.5 mm). The module is portable and at 4 sq ft (1.22 meters) offers a small footprint.

While new folding-gluing machines can be specified with Braille systems, the Rapid Braille Module is priced at a fraction of these new machines and is compatible with all existing folder gluers. This means a much lower cost and overall less equipment to add Braille capabilities to an existing packaging line.

But whatever the solution to comply with the EU-directive, one of the problems with Braille embossing is the dot accuracy. The Braille dot height is an important issue to packaging manufacturers as their customers has to be ensured that the Braille images provided comply with the EU-directive.

But whatever the solution to comply with the EU-directive, one of the problems with Braille embossing is the dot accuracy. The Braille dot height is an important issue to packaging manufacturers as their customers has to be ensured that the Braille images provided comply with the EU-directive.

Therefore Troika Systems Limited, a UK-based company developing print-based quality control products, came up with the BrailleCAM, a device designed to accurately measure Braille dots, as the EU legislation not only requires the incorporation of Braille information on all new drug packaging, but includes detailed specifications for the height of the Braille dot.

The current technology to measure Braille dots is limited - typically in the form of a micrometer. Such rudimentary technology requires a large number of samples to provide the confidence levels required. BrailleCAM, based on Troika’s technology for measuring the dot on a flexo-graphic plate, is a far more sophisticated tool. It is both precise and consistent, and provides an array of further information to fine tune the Braille process.

The current technology to measure Braille dots is limited - typically in the form of a micrometer. Such rudimentary technology requires a large number of samples to provide the confidence levels required. BrailleCAM, based on Troika’s technology for measuring the dot on a flexo-graphic plate, is a far more sophisticated tool. It is both precise and consistent, and provides an array of further information to fine tune the Braille process.

BrailleCAM is a hand-held, portable camera specifically designed to measure and view Braille dots with unrivalled precision and clarity. When measuring finished product, the auto-focus feature of the camera automatically finds the top surface. It then takes a series of images, each with a different focus depth, down to the ground level of the substrate. Software removes all un-sharp parts of each image and combines the levels into a rendered 3D grid model. This can be analysed via the PC and rotated in any direction.

The BrailleCAM provides clear 3D images of the Braille dot and tooling. It provides the dot height, profile plot, alignment, symmetry and diameter. The system also provides the tools necessary for highly detailed measurement and recording of dot values. BrailleCAM can measure male and female embossing tools as well as final output.

* This year it is 200 years since the Frenchman Louis Braille (1809-1852) was born. Following a new EU directive (2004/27/CE No) which requires all packages of pharmaceutical products to bear the Braille characters, several packaging companies have developed their own unique technology to add Braille characters to the surfaces of packages. In the article “Braille and Packaging” I describe successively Sleever Braille, CCL’s BrailleMarker, the AccuBraille system of Bobst and Nordson’s e.dot.

This year it is 200 years since the Frenchman Louis Braille (1809-1852) was born. Following a new EU directive (2004/27/CE No) which requires all packages of pharmaceutical products to bear the Braille characters, several packaging companies have developed their own unique technology to add Braille characters to the surfaces of packages. In the article “Braille and Packaging” I describe successively Sleever Braille, CCL’s BrailleMarker, the AccuBraille system of Bobst and Nordson’s e.dot.

About the Author(s)

You May Also Like