January 29, 2014

Since its humble creation in 1886 by Atlanta pharmacist Dr. John Pemberton, the Coca-Cola soft drink beverage has been called everything from "The Ideal Brain Tonic" (1893) and "The Pause that Refreshes" (1929), to the "Friendliest Drink on Earth" ('56) and the "Real Thing" ('43, '70). In its first year, the groundbreaking carbonated drink was purchased approximately nine times a day in Jacobs' Pharmacy in Atlanta. By 1986, more than 10 billion gallons of syrup had been produced by The Coca-Cola Co., and the drink was making its way across the globe. But, no matter how the beverage has been marketed or how large the enterprise has grown, the company's ideals have remained unchanged.

"Nothing is more important to our success than integrity," reads the company's website. "This begins with insisting on absolute quality for every one of our products, and acting with a strong sense of accountability in everything we do."

Vital in communicating the company's message of quality and integrity is its product packaging, which employs trademark graphics and colors for immediate brand recognition worldwide. A trusted partner in ensuring this consistency and quality for many of its canned beverages is Rexam Beverage Can Americas (Rexam BCA), headquartered in Chicago.

Coca-Cola often works with Rexam BCA to reproduce its desired brand image on aluminum beverage cans. This work is accomplished in Rexam's state-of-the-art graphic art organization within the company's Beverage Tech Center in Elk Grove Village, IL. The artwork discussed in this article adorns a product that perhaps best epitomizes the soft-drink giant's legacy: Coca-Cola Classic. Using its extensive prepress capabilities and pilot canmaking and decorating line, Rexam BCA often sets the reproduction standards for Coca-Cola Classic to be used not only by its own canmaking plants, but also by competing can manufacturers.

Tech center ensures consistency

With the only company-owned, completely integrated beverage can technology center and pilot assembly line, Rexam BCA provides services that enable it to "become a business partner" with its beverage can customers, says Al Bohner, vp of manufacturing, engineering, and research and development, Rexam BCA. It is in the 12,000-sq-ft Elk Grove Village facility that more than 24,000 engravings per year are perfected, and nearly 65,000 plates per year are output for customers in the U.S., Brazil and Mexico.

|

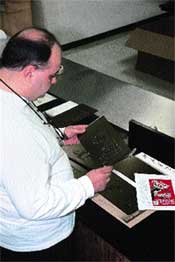

New artwork from Coca-Cola makes its first stop at the graphic arts department, where technicians add 0.005-in. channels around artwork and text, and match Coca-Cola-brand color specs, left. Separated films, right, are inspected for pinholes and trapping accuracy. |

Offering its customers a larger degree of confidentiality for new products and can graphics than available with canmakers that outsource their engravings and/or plates, Rexam BCA also enables a can to be reproduced as many times as necessary on its pilot line to reach an acceptable final product.

Explained Mike Adamec, Rexam BCA graphic art and printing plate manager, to Packaging Digest during a recent tour, "The reason we're unique at this operation is that we take a piece of artwork, make the separations and printing plates, and put the plates on a decorator. So, if the customer wants to modify a design, we can make the changes immediately right on our computer, make plates and be back out on the decorator the same day. To be able to handle these requests in-house, this fast, is unique in the industry."

But Rexam BCA's graphic artwork and printing plate department's work begins long before the pilot line stage. "Our responsibility to customers is to get involved at the very beginning of a can design and work with them closely in the transfer from design to can production so we can eliminate any problems before the cans are on the printing lines," Adamec says.

The current Coca-Cola Classic design, titled Sensation Graphics, has been on the market for a few years. The original artwork, brought to Rexam BCA via Zip, offered several potential printing pitfalls. Against a Coke-red background, the can graphics depict the rim of a green glass bottle, from which a splash of caramel-colored cola sprays, with the bottle's cap propelling upward.

|

A video-based measurement system tests film and plates for stability, and measures the size of and the distance between the plate's holes, for complete accuracy. |

Explains Jim Welch, graphic art desktop supervisor for Rexam BCA, "It's a difficult image to transfer to a can because the design has a closely connected 'swash' running through it that is printed in two strongly contrasting colors–red and black. This means that it will vary when printed, depending upon how much red or black is placed on the can.

"Our intention," he continues, "was to eliminate the possibility of contamination or variance in color during printing." The final design uses a combination of white, red, green and black, laid down in that order.

A team effort

In the case of Coca-Cola Classic, initial separations were produced by a Cola-Cola supplier, Cocks-Clark Graphics in Denver, which worked closely with Rexam BCA. Another partner in the design creation process was ink supplier INX International, which often collaborates with Rexam BCA to determine the proper ink tacks for each of the colors in a design.

After receiving the digital artwork, Rexam BCA responded to Coca-Cola with a digital proof and finished separations. Upon Coca-Cola's approval of the separations, Rexam BCA created plates for those manufacturing facilities within its network producing the can, and conveyed the printing standards for the finished designs to its plants. "We have a complete toolbox that goes with the design," explains Adamec. "We supply the plants with the light, standard and dark tolerances, a sequence of operation as to how we put the colors down, and the ink formulations."

Complete prepress services

Rexam BCA's prepress, engraving and platemaking operations boast an impressive lineup of equipment–times two. For every piece of equipment, a second, backup machine exists. And, backup doesn't end with the equipment, either. All finalized designs are stored digitally both on- and off-site.

Each design entering the all-Macintosh environment makes its first stop at the desktop department, where technicians add 0.005-in. channels, or lines around the edges of all artwork and text. These channels remain free of ink during the decorating process, preventing adjoining colors from mixing, or becoming contaminated. Once the channels are added, a proof is produced to verify placement of the graphic elements.

The proofing system also allows technicians to generate ink coverage percentages that aid customers in predicting ink mileage and costs. For example, the design for the Coca-Cola Classic can requires 20-percent white, 53-percent red, 2-percent green and 15-percent black ink. Nine percent of the design is bare aluminum.

After proofing, designs are sent digitally for film-making to an Agfa SelectSet Avantra 30 imagesetter driven by an Agfa Taipan RIP (raster image processor). The 30 x 25-in. Avantra 30 offers a maximum line screen of 425 lines/in.–more than adequate for the 85-lpi screens used in can decorating. Here, registration pins are also added.

Films are then inspected for pinholes and the accuracy of traps, and the UPC symbol is verified. Next, unexposed photopolymer plates from Toray are punched, using a Ternes plate punch, so that they will fit the pins on a standard magnetic chuck supplied by T.D. Wright. The holes punched on each plate ensure that artwork will align properly once the job is run on-press.

Next, punched plates are exposed via a computer-driven Misomex step-and-repeat machine from AGFA, and then processed in alcohol using a model DW 100 EX automatic plate processor from BASF. Drying of the 0.032-in.-thick plates is accomplished using ovens from Global Graphics Hardware, formerly Kelleigh Corp.; post-curing is done on a high-intensity ultraviolet unit.

|

A technician inspects exposed and punched plates for the Coca-Cola Classic can. |

Giving Rexam BCA even more of an edge over its competitors is a video-based measurement system from Acu-Gage that tests film and plates for stability, and measures the size of and the distance between the plate's holes for complete accuracy.

In the last step, plates are cut to size and packaged for next-day delivery. For its facilities producing the cans, Rexam BCA also sends separations, as well as single pulls of the cans to demonstrate how each color appears on the can by itself.

Pilot line is invaluable

The importance of the Rexam BCA pilot line–the only one of its kind in the U.S.–for producing finished cans for evaluation cannot be underestimated. The line permits small-scale manufacturing of beverage cans with a necker flanger built in-house, as well as decorating by way of a Polytype CP200-24-8 eight-color decorator.

For Rexam, the line eliminates costly downtime within the manufacturing environment. "It's very costly to run a color proof on a manufacturing line," explains Adamec, "so if we get the bugs out before the cans are produced in our larger manufacturing facilities, we save time and money, and we increase quality.

The 24-mandrel pilot-line decorator, which can be adjusted to accommodate a range of can sizes, not only allows customers to tweak their designs before mass-scale production, but it also provides them with usable product for trials and promotions.

"Coca-Cola has allowed us to use our pilot line for all initial runs of their designs," notes Adamec. "We don't go into the canmaking plants to see if the designs will work. It's all done beforehand on our pilot line. Coca-Cola is confident enough in our system to allow us to do that."

For more information:

Engraving, platemaking, can converting: Rexam Beverage Can Americas, 773/399-3000. Circle No. 231.

Engraving: Cocks-Clark Graphics, Inc., 303/292-6242. Circle No. 232.

Ink: INX International Ink Co., 800/545-4469. Circle No. 233.

Imagesetter, RIP: Agfa Corp., 201/440-2500. Circle No. 234.

Plates: Toray Industries (America), Inc., 212/697-8150. Circle No. 235.

Plate punch: Ternes Register Group, 651/407-4800. Circle No. 236.

Magnetic chuck: T.D. Wright, Inc., 800/896-1302. Circle No. 237.

Platemaker: AGFA Corp., 201/440-2500. Circle No. 238.

Plate processor: BASF Drucksysteme GmbH, +49 (0)711/98 16-0. Circle No. 239.

Dryers: Global Graphics Hardware, Inc., 609/530-1300. Circle No. 240.

Measurement system: Acu-Gage Systems, 800/422-2283. Circle No. 241.

Decorator: Polytype America Corp., Converting Equipment div., 908/852-3200. Circle No. 242.

Santa can an award-winner |

Making spirits bright at Coca-Cola and Rexam BCA, the beverage company's annual Santa Claus promotional can?among the most recognizable consumer packages in history, according to Rexam BCA–won the 2001 |

About the Author(s)

You May Also Like