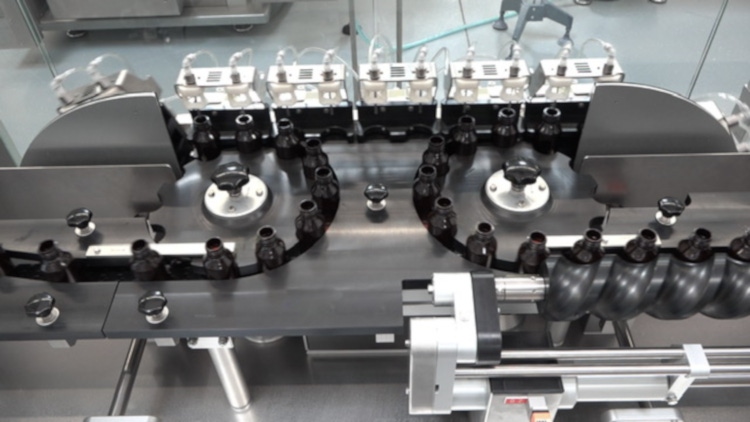

The recently launched FlexClean air-rinsing machine offers healthcare and cosmetics packagers a flexible option for cleaning bottles prior to filling with liquid products. The unit “rinses” bottles by blowing out unwanted particles.

Because the machine from groninger has an oval design, bottles are upended and rinsed longer than on a rotary-design unit. In addition, the FlexClean machine’s base holders can accommodate various transport carriers, boosting operational flexibility. One, two or three containers (depending on size) may be mounted on the base holders, with line speeds increasing accordingly.

Michael Steck, design team manager at groninger, answers Packaging Digest’s questions about the system.

What types of bottles are compatible with the FlexClean machine?

Steck: Any type of bottle and material is compatible with our FlexClean air-rising machine. In most cases, customers ask for glass or plastic, but metal would also be possible.

What is the size range for bottles going through the FlexClean?

Steck: It depends on different aspects. First, the shape of the bottles—whether they are cylindrical or not. Second, the size of the bottles. Cylindrical bottles are differentiated between small (16 to 40 millimeters), medium (40 to 60mm) and large (60 to 100mm) size. In place of one large bottle, you can either process three small ones or two medium ones. This means an output of 180, 120 or 60 bottles per minute.

What types of products are typically filled into bottles?

Steck: It is up to the customer, of course. Using the FlexClean machine especially makes sense if you want to fill liquids in the consumer healthcare or cosmetics industries. So far, the bottles cleaned by the FlexClean are being filled with eye drops and cough syrup. But almost every kind of liquid product in the consumer healthcare and cosmetics industries—for example, oral hygiene, health supplements, diagnostic, skincare and haircare products—can be processed.

What line modifications need to be made when adding the FlexClean machine to an existing filling line?

Steck: The ready-engineered approach of the FlexClean machine makes possible a quite simple integration into an existing packaging line. It does not have its own control system, so there are hardly any modifications to realize. And if needed, groninger can also design it as a standalone machine, though not ready-engineered.

Does FlexClean have commercial installations yet?

Steck: Although we only just launched the FlexClean machine concept, one FlexClean is now on its way to getting installed, and a second one is just being built in Schnelldorf, Germany. Both lines will be installed to fill cough syrup.

About the Author(s)

You May Also Like