February 1, 2014

ACC Manufacturing, Manchester, U.K., one of the largest dairies in the United Kingdom, recognizes that innovation and convenience are key in a competitive market. By transitioning its rice pudding and custard cans to feature easy-open ends, it has created a customer-friendly package that enhances brand equity in a crowded playing field.

"Easy-open ends are the ultimate in convenient consumer packaging. No can opener is required, and packages instantly become portable," says Chris Green, ACC's commercial manager for consumer products. "We saw that easy-open ends were being introduced on products like beans and soup, and we knew it was only a matter of time before consumers expected them on dairy products as well. Making the switch early positions ACC as an innovator."

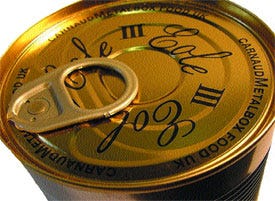

Seeking an easy-open end that matched the performance and quality of standard ends, ACC turned to Crown Cork & Seal for its economical Eole (pronounced ee-ol) III high-performance easy-open solution.

Seeking an easy-open end that matched the performance and quality of standard ends, ACC turned to Crown Cork & Seal for its economical Eole (pronounced ee-ol) III high-performance easy-open solution.

Adding value for customers

ACC is a major manufacturer of rice pudding and custard products for both the ACC label and other branded products. Maintaining brand appeal was a key concern when considering the switch to easy open ends.

"We've been following easy-open-end technology for quite some time," says Green. "Crown's development of Eole III convinced us to make the change." Crown released the third generation of the Eole in 2001. Originally developed by Carnaud Metalbox, Eole has existed in one version or another for at least 10 years.

Easy open ends are judged according to the following features: tab access to lift the tab; pop force to pierce the score; tear force to initiate the peel; and peel force to remove the panel. These forces are particularly important, as they define whether the consumer feels and actually is in control during opening, PD is informed. The lower the force required, the greater the acceptability by consumers.

Manufactured using thinner and harder double reduced steel, Eole III decreases the force required to open the can by 25 percent. It is significantly smoother and easier to open without spillage, while not compromising superior performance through filling, handling and distribution channels, Crown says. Tabs are positioned so they are more accessible but still lie flat enough to prevent catching in filling and processing machinery, and to allow for efficient stacking.

Manufactured using thinner and harder double reduced steel, Eole III decreases the force required to open the can by 25 percent. It is significantly smoother and easier to open without spillage, while not compromising superior performance through filling, handling and distribution channels, Crown says. Tabs are positioned so they are more accessible but still lie flat enough to prevent catching in filling and processing machinery, and to allow for efficient stacking.

Making the switch

The transition from standard ends to Eole III proved to be a smooth and economical solution for ACC. No large upfront investment was required, and only minor machinery adjustments were necessary. Green adds,"The changes that were needed were absolutely minimal. In total, the changeover took only a few weeks." To date, the transition has been smooth, and the new ends are expected to solidify ACC's position against competitors. "Customer reaction has already been extremely positive and supportive," says Green.

While still too early to quantify the impact of the new ends, ACC is optimistic. "By going technologically where our competitors haven't, we have demonstrated our commitment to innovation," Green says. "Eole III has already given us a better relationship with our buyers."

More information is available:

Can ends: Crown, Cork & Seal, Inc., 740/681-6521. www.crowncork.com

.

About the Author(s)

You May Also Like