For the most part, packaging operations are pretty satisfied with the coding technology they are using to apply date codes to packages, with inkjet leading competitive options. But will existing capabilities serve future expectations?

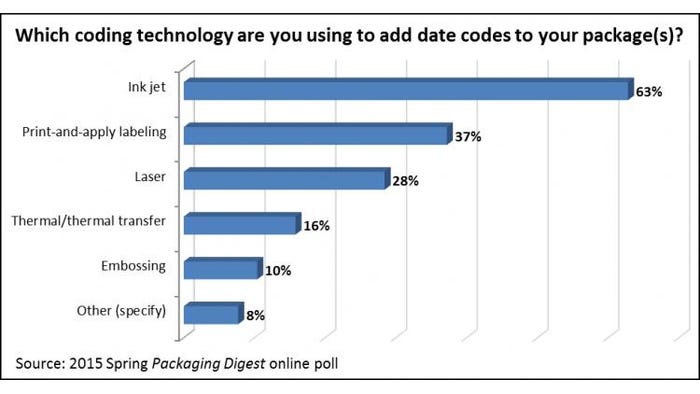

In a Packaging Digest exclusive poll on Date Coding, respondents identified the various coding technologies they are currently using to add date codes to their packages. The frontrunner, inkjet, scored a healthy 63%. Next up at 37% is print-and-apply labeling, which is somewhat surprising when you think that the vast majority of date codes are added to primary packages and p/a labeling is typically seen more on shippers.

Laser wins a respectable third place at 28% but is up-and-coming as a replacement (more on this in a bit). Less-used technologies of thermal/thermal transfer and embossing are fourth and fifth at 16% and 10%, respectively. And only 8% selected “Other,” as identified as hand or rubber stamps and manual date wheels on one end of the spectrum, and as pre-printed codes when the package is printed on the other end.

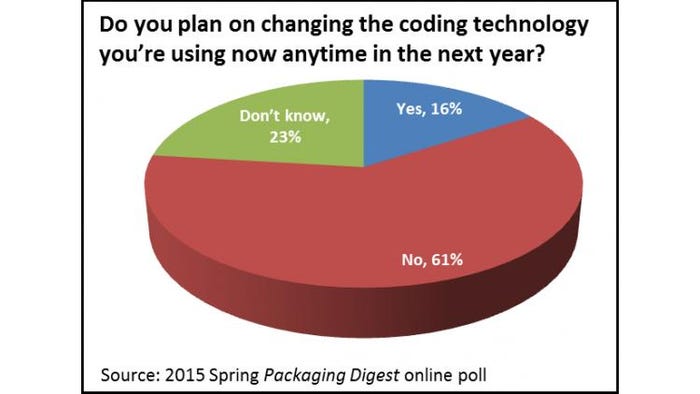

The majority (61%) do not plan to change the type of coding technology in the next year. For participants currently using inkjet, though, 69% say they do not plan on changing in the next year.

However, nearly 40% say, yes, they do (16%) or they don’t know (23%). That’s a hefty chunk of the pie.

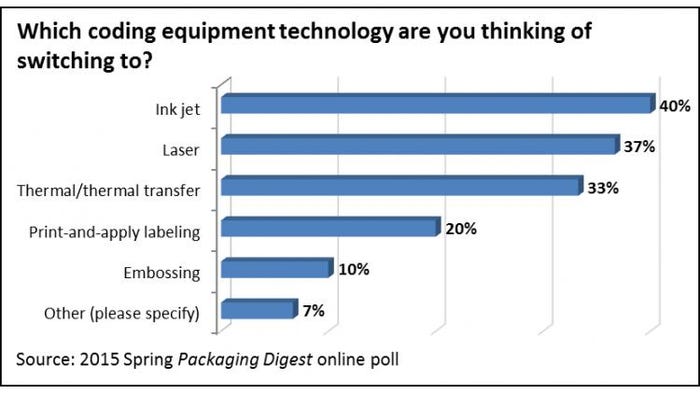

Yet inkjet still comes out on top as the go-to replacement, with 40% of poll participants leaning toward the familiar technology. Laser isn’t far behind though at 37%, beating out thermal/thermal transfer (at 33%) by a small margin. At 20%, print-and-apply labeling still has a following, again somewhat curiously to me. Embossing brings up the rear at just 10%. The 7% who choose “Other” admit that they don’t know what technology they would switch to.

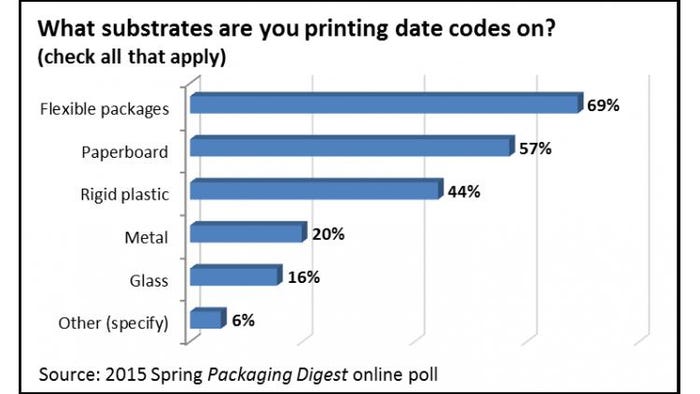

The type of substrate the code is printed on could make a difference in the technology used, so we also asked about the materials. Our numbers reflect what we’ve been seeing in the market, with flexible packaging at the top and glass trailing. Write-in items from “Other” can be categorized into corrugated and labels (paper and film).

Code legibility, accuracy and high-speed application are top concerns for those responsible for the date coding operation on packaging lines. Here are some other production challenges poll respondents shared:

“More and more information required that may exceed the limitations of inkjet printing (# of lines / length of text).”

“Use of laser coding to reduce hazardous waste and consumables cost.”

“Accuracy and placement keeping up with higher speed lines.”

“I see packaging is always changing so new technologies may need to change.”

“In some of the developing countries automatic machinery is not used. Most equipment is designed for automatic machinery. We are still working on manual packaging systems.”

“Improved quality of coding legibility and reduction in missing package coding.”

“Higher print speeds.”

“Will become a requirement for small business.”

This is Part 3 of our series on the results from our Spring 2015 date coding survey, which was conducted online and had 367 respondents. Part 2 explored the interest in and use of smart sensor technologies and quick-response (QR) codes. Part 1 of our survey results revealed that “Best by” was the phrase the majority of companies prefer to use for their date codes.

Do you have any suggestions for other survey topics? Send your ideas to [email protected] or add a comment below.

About the Author(s)

You May Also Like