Two new indivi

H-adept g-s.jpg

dually quick-frozen (IQF) vegetable lines at Haliburton Intl. Foods are pushing the limits of packaging technology. "I used to do this for big companies, so I decided to start a company that would use the most advanced technology to achieve maximum food quality at the best prices," says founder and president Ian Schenkel.

Established in 1992, Haliburton Intl. Foods has grown into a specialty foods powerhouse. It services the nation's largest retailers, national restaurant chains and top 100 food manufacturers from a newly constructed 120,000-sq-ft, state-of-the-art manufacturing facility in Ontario, CA.

With more than 90 percent of its products made from fresh vegetableds, the plant processes more than 20 tons of fresh food every hour-from artichokes, carrots, eggplants and garlic to mushrooms, onions, peppers and zucchinis. Haliburton offers 40-plus vegetable varieties in more than 250 different forms.

The newest operation is the two automated packaging lines running 4 oz through 5 lb bags of frozen vegetables for foodservice and retail at speeds to 140 packages/min. "I started with the scales and baggers, and proceeded from there," says Schenkel.

"The Ilapak bagger and Yamato scale can run 15 bags/min faster than any other equipment on the market, and the Adept robot is the fastest pick-and-place robot available. All of the other robots that we looked at would have required two robots on each line. Adept does it with a single robot."

The other requirement is food safety and traceability. "I was going to install metal detectors, but the Anritzu x-ray system is the most sensitive inspection system on the market. It can detect particles as small as 0.3 mm of just about any material," says Schenkel. "We apply a 2-D bar code to every bag and case, and we store a digital image of each bag, case and pallet on our server so we can track everything we make all the way to the end user."

High-speed scales

The two new IQF lines at Haliburton are identical. A Yamato Corp. Dataweigh Sigma F614SV Frontier 14-head radial weighing system is mounted on a platform above the bagger. Product is weighing statiions that

H-scale.jpg

delivered from the processing area in bins to each line, and a vertical bucket elevator lifts it to the scale platform. The elevator discharges into a vibratory feeder that discharges into the vibrating top cone of the Yamato weighing system. The elevator and vibratory feeder were supplied by Deamco Corp. Ltd. A programmable load cell under the center cone turns the product discharge on and off to maintain the proper product level on the cone.

The Yamato weighing system consists of 14 individual weigh heads mounted around the vibrating top cone. Each head consists of three main components: vibrating feed pan, feed bucket and weigh bucket. Product discharges from the cone into the vibrating feed pan, which delivers product to the feed bucket. The on/off vibrating pan operates for a preset period of time to put a set amount of product into the feed bucket.

The feed bucket, in turn, drops product into the weigh bucket. The amplitude of the vibrating pans changes automatically to adapt to product-flow changes and to maintain accuracy and efficiency. Individual programmable stepper motors open and close the feed bucket and the weigh bucket without the use of either external or internal springs.

The amount of product delivere

H - Illapak.jpg

d to each weigh-bucket is about one-third to one-sixth of the weight of the finished package, depending on that weight. For each weighment, the control system selects the combination of three or four buckets (for small bags) and six or seven buckets (for large bags) that comes closest to the total bag weight without being under that weight.

The Frontier series scales at Haliburton have two internal product paths. They can produce two complete charges of product simultaneously and discharge them into separate timing hoppers directly above the vertical packaging machine.

The two product charges discharge into the packaging machine in the proper timing to separate one charge from the other to allow for clean hermetic seals of the final package by the packaging machine.

Typically, the system achieves accuracies of about 1 to 1.5 g overweight. Each discharge is displayed on the computer monitor, showing the fill weight, exactly which scales released product and statistical data for each production run.

The weighing system automatically calibrates itself for bulk product as it passes through the system, tracks the product and continuously compensates and updates itself for optimal sensitivity.

Continuous-motion vf/f/s

The product discharges from the scale into a continuous-motion Model Vegatronic 4000SP vertical form/fill/seal machine from Ilapak Inc. Haliburton is currently running pillow packs, but the machine can also run gusseted pillows, block bottom and four-corner, center seal Quattro Pak bags in continuous mode. The machine can run PE and heat-sealable films in high-speed continuous mode.

The film is mounted on the back of the continuous-motion bagger and is pulled into the machine by Ilapak's proprietary servo-driven Dynamic Film Feed Roller System, which electronically controls the film tension and maintains the position of the film horizontally. A motor on the shaft holding the film roll regulates the unwind speed and also helps maintain film tension.

The film travels over a roller and down the front of the unit, where it passes around a forming tube, and a rotary band induction heater produces a vertical overlap seal. Two belts on opposite sides of the forming tube help pull the film through the machine.

The IQF vegetables drop intermittently from the overhead weighing system through the forming tube into the continuously moving formed cylinder of film as it leaves the vertical forming section.

Next, the film passes through the continuous-motion, servo-driven sealing jaws, which move synchronously with the film. The jaws close, and an induction-heat, horizontal seal across the film is produced while moving with the film.

The seal jaws then move away from the film and reciprocate upward to start the next sealing cycle. The jaws have separate servo motors for the auto-sychronized up/down and open/close motions. The bag length and sealing jaw pressure are electronically measured and adjustable.

At the end of each sealing cycle, before the jaws disengage, the seal is air-cooled, and an air-actuated blade shoots out from the center of the jaws and cuts the bag loose, after which it drops onto the takeaway conveyor.

Haliburton is currently running clear film that does not have an eye mark, so an encoder wheel measures the length of each bag and adjusts the speed of the pull belts described previously and compensates for any slight changes in the film length. This ensures that the length of each bag is always correct

The bagger incorporates Allen-Bradley Control Logix from Rockwell Automation for system control. An AB Panel View 1000 HMI is mounted next to the machine for easy access. The HMI features a touchscreen with user friendly graphics and a comprehensive menu that enables the operator to set the operating parameters for each product and bag size, then save it in memory. It also includes machine diagnostics. The controls trigger each weighment from the Yamato weighing system.

Larger bags, such as the 5-lb size, require multiple scale discharges to fill the bag. In this case, the vf/f/s machine is operated in intermittent mode, with the bagger stopped during multiple scale discharges into a single bag. This mode of operation is selected by the operator from the menu on the HMI.

The standout feature of thi

H- tape.jpg

s Vegatronic 4000SP system is versatility to produce virtually any type of package Halliburton requires from one single machine, either in continuous or intermittent mode of operation.

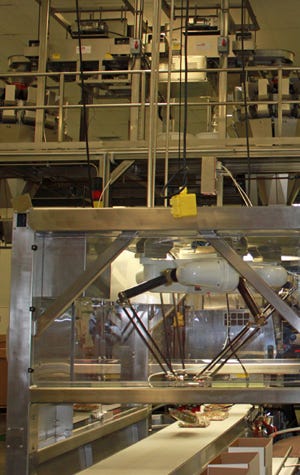

Pick-and-place robot

Bags of vegetables drop onto a conveyor, and Haliburton is planning to install a printer that will apply a 2-D code to every bag. This will be the source of the data that will be stored. The bags then pass through a Model KD7400 Series X-Ray inspection system from Anritsu Industrial Solutions USA. The unit uses a combination of variable X-Ray power technology and a series of complex computer algorithms to detect metal, glass, stone, bone and rubber contaminants as small as 0.3 mm. Its mass measurement capability enables the unit to also serve as a virtual checkweigher with an accuracy of +/-2 g.

The system incorporates Anritsu's QuiCCA (Quality Improvement by Control, Collection and Analysis) system, which monitors and records the normal operation of the x-ray system unit and continually analyzes the data to detect abnormalities. QuiCCA is connected to a 20-terabyte storage system, where a serialized image of every package is collected, analyzed and stored.

The bags then enter a packaging automation cell from Adept Technology Inc. where a Quattro s650HS parallel vision-guided, pick-and-place robot packs the bags into corrugated cases located on a conveyor beside the cell. In this operation, an encoder-equipped camera above the conveyor at the entrance to the unit takes a picture of each entering bag. The encoder remembers the bag's position on the conveyor and directs the robot where to pick it up.

The case conveyor also is tracked by an encoder allowing both the product infeed and the case conveyor to continue moving during the case packing. Though this is a secondary packaging application, the USDA-accepted robot gives an extra level of assurance for food safety.

The unit incorporates Adept's Pack Expert packaging software, which eliminates the need for operator programming. PackExpert handles all of the standard packaging jobs and allows Haliburton to change pack patterns and products with technical expertise found on the plant floor. This is important to handle Haliburton's high product mix and evolving business. It also uses an Adept vacuum gripper system that has a 5-kg weight limit to grasp the bags. The gripping solution is a unique patented solution developed by Adept's Denmark division specifically for the food industry. It is a high flow, low vacuum gripper, which conforms to a hand to grip product.

The corrugated cases are prin

H- fanuc.jpg

ted and erected offline by an Iconotech flat-case digital printer followed by a Pearson Packaging Systems Model CE25-T erector that tapes the bottom of the cases. The cases are then conveyed to the robotic packer on a conveyor from Pacific Conveyor Systems, which supplied all of the conveyors used in the operation. The cases travel through a Pearson Packaging Model CS25-ST case sealer that closes the minor and major top flaps and applies a strip of tape to seal the tops of the cases.

Eco-friendly case coder

The cases then travel up an inclined conveyor and pass through a Model Aplink MR series inkjet printer from UBS Coders that was developed specifically to print high-quality bar codes on corrugated boxes. The printer gets a bar code reading from the bags entering the Adept cell and automatically prints a corresponding 2-D bar code on the case.

According to the manufacturer, this is the world's only green case coder. Its ink base is a vegetable-based mineral oil that contains no solvent and no wax. The unit has a Seiko piezo printhead that requires no cartridge, so there is no purging and no annual replacement of heads. This printer is linked in a closed loop to a print-and-apply labeler that applies labels with the same 2-D bar code to stretch-wrapped pallets of product.

The cases continue to a palletizing cell from Flexicell Inc. that includes a Model M-410iB robot from Fanuc Robotics America Inc. The M-410iB is a four-axis, servo-driven robot with an integral mechanical and control unit. The end-of-arm tool (EAOT) is a patented Flexicell "Servo Gripper," which uses an array of vacuum cups to pick up the cases. This EOAT is capable of handling different size cases and automatically adjusts itself so no operator intervention is required.

The cases are delivered to a fixed point and the pallet is also in a fixed location, so the robot knows where to pick up the case and where to place it. The product being run is selected from the menu in the robot control and this automatically selects the proper stacking pattern.

Finished pallets are stretch wrapped, after which two labels are printed and applied to each pallet. This is done by a UBS Coders Model APL 8000 series machine that was specifically designed for use on pallets. A sensor detects when a pallet of product is in place, and a reader scans the bar code on the cases and the unit prints corresponding labels. A pneumatic arm swings in, strips the labels from the machine one at a time and applies them to two adjacent sides of the pallet. The unit incorporates a thermal printer from Datamax-O'Neil to print the labels.

The Anritzu and UBS Coders equipment is represented on the West Coast by Package Devices.

Most of the equipment here uses Rockwell Automation controls, which are standard for the plant.

"This is a state-of-the-art line, and it has performed exactly like we expected," says Schenkel. "We wanted the best equipment that was available for every operation, and price was not our first criterion for selecting equipment. We could have purchased less expensive equipment, but our investment in advanced technology has given us higher output and better quality and actually reduced our unit costs. We are happy with our choice of vendors."

Adept Technology Inc., 925-245-3400. www.adept.com

Anritsu Industrial Solutions USA, 866-200-5276. www.us.anritsu-industry.com

Datamax-O'Neil, 800-816-9649. www.datamax-oneil.com

Deamco Corp. Ltd., 800-933-2620. www.deamco.com

Fanuc Robotics America Inc., 248-377-7000. www.fanucrobotics.com

Flexicell Inc., 804-338-1160. www.flexicell.com

Iconotech, 800-521-0194. www.iconotech.com

Ilapak Inc., 215-579-2900. www.ilapak.com

Pacific Conveyor Systems, 714-258-1810. www.pacificconveyor.net

Package Devices, 310-546-4249. www.packagedevices.com

Pearson Packaging Systems, 800-732-7766. www.pearsonpkg.com

Rockwell Automation, 414-382-2000. www.rockwellautomation.com

UBS Coders, 760-480-0777. www.ubscode.com

Yamato Corp., 800-538-1762. www.Yamatoamericas.com

About the Author(s)

You May Also Like