For food manufacturers and packagers, the current and future impact of the COVID-19 pandemic on the supply chain is a nagging concern. A recent webinar about today’s coronavirus challenges offered insight into the supply chain disruptions and how businesses can manage that risk.

The COVID-19 Strategies for Managing Food Supply Chain Risk webinar, sponsored by FoodChain ID, included information on maintaining food-safety certifications if a company’s regularly scheduled audit is coming up in the next few weeks or months.

For companies in that position, several of the major Global Food Safety Initiative (GFSI) Certification Program Owners have already made provisions for six-month certificate extensions. Prior to granting such an extension, the certifying body may conduct a remote audit of the company and will perform a risk assessment based on information from the company regarding how its business has changed since COVID-19.

For example, will the company need to use alternative manufacturing sites? Will it need to identify and approve new suppliers? What has it done to address such issues?

Supply chain disruption or additions may necessitate approving a new supplier location without an on-site audit. Note that all GFSI standards include an “emergency approval” clause, for the approval of new suppliers during situations like the current one.

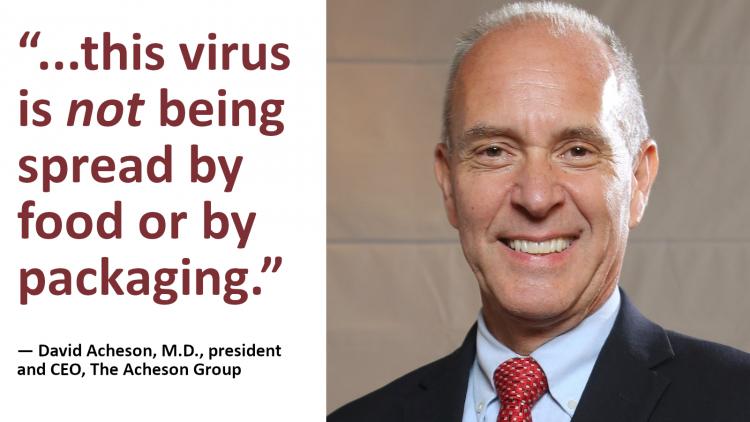

“The American public is relying on us to continue to provide them with food, and importantly, safe food. So while we’re dealing with all these other moving parts — new risks, new requirements — we have to maintain our basic food-safety requirements,” said David Acheson, M.D., president and CEO of The Acheson Group.

Although the FDA has postponed routine surveillance inspections because of the pandemic, it will continue with “mission-critical” for cause inspections. Recalls will continue to occur, as needed.

As for COVID-19 and food, “the approach that FDA has taken in this regard, which is reflective of other regulatory agencies across the world, is that this virus is not being spread by food or by packaging,” Acheson said.

The virus will not grow on food or surfaces, he noted, but it can survive on paperboard for 24 hours, and on plastic and stainless steel for two to three days. Most cleaning and disinfecting chemicals used in manufacturing plants will destroy the virus.

Addressing the seemingly conflicting messages of the virus being able to live for a time on packaging but not being spread by it,Kevin Kenny, regulatory attorney and chief operating officer of Decernis, said: “The primary risk around spreading this virus is not the packaging. It’s not even the food. It’s the social interaction.”

Packaging, Kenny said, poses “a very low risk compared to standing in line behind somebody who is shedding [virus].”

Acheson concurred, adding that “packaging is not the place to focus. We know the virus will survive on it … but the virus is not going to [jump] off the packaging and into your eyes or your nose or your mouth. It’s going to die on the package. It’s not going to multiply on the package.

“Don’t fear handling packaging, but do fear not washing your hands after you’ve handled the package and touching your nose. That’s where you can break the transmission. … This is about breaking the transmission chain.

“The key thing is, if you’ve touched something that you deem to be a high risk, or you don’t even know, wash your hands before you do anything else. You’ve handled it, wash your hands. You’ve handled something else, wash your hands. Wash your hands. Wash your hands.”

Acheson also emphasized the importance of protecting the work force from COVID-19. As an expert in food-safety best practices and an infectious-disease specialist, he advised companies to focus on the primary methods of transmission to thwart viral spread among their employees.

In addition to frequent hand washing, tactics include use of appropriate personal protective equipment (PPE); social distancing; use of hand sanitizers; and not touching one’s eyes, nose, and mouth.

When employees get sick at work, it’s essential to immediately isolate them and get them home. “Removing them from the work force, obviously in a kind and understanding way, is important,” Acheson said.

It’s also important to determine where those employees have been working in the past 48 hours, when they had no symptoms but were transmitting the virus to others. The company should identify the sick person’s close contacts at work and send them home, as well, to self-isolate for 14 days.

Companies can reduce risk by reconsidering their shift structure, segregating groups, and practicing social distancing, plus hourly touchpoint cleaning of common areas. They should also develop a visitor policy, excluding all visitors other than essential ones and providing wellness checks for necessary visitors.

Finally, to protect food and agricultural workers from citations for violating stay-at-home orders, employers should give them a letter stating that they are part of critical infrastructure.

“There are several states that are imposing spot fines,” Acheson said, so provide workers with “documentation from you, on your letterhead, with a contact number, so that they can feel confident that if they get pulled over, they’re going to be okay.”

Bottom line, companies should plan for a business disruption lasting at least the next three to four months. The situation is rapidly changing. To stay on top of it, brand owners and packagers can visit FoodChain ID’s regularly updated COVID-19 Updates & Resources page.

About the Author(s)

You May Also Like