Most packaging professionals have always felt they contribute a vital service to the world. They do. That’s more evident to the general public now because of the coronavirus pandemic. Here’s how the packaging community has been responding to the crisis.

Virtual learning opportunities abound.

Most people are taking the social distancing edict seriously. Thank you. We are finding that there is a lot of work we can do remotely.

In my earlier article “4 Ways Packaging Can Help During the Coronavirus Crisis,” I asked you to keep focused on the important packaging issues, and to keep the conversations / learnings going. As predicted, virtual events have ramped up now that in-person group events are temporarily nixed.

For example, the Sustainable Packaging Coalition had to cancel its highly valued SPC Impact conference, scheduled for late March/early April. But several sessions have been retooled as free webinars. Click here to see all the topics and times. Hurry, though, because some are taking place as soon as March 31.

Silver lining: Cooped up consumers may recycle more.

Sustainability has been and will continue to be one of the hottest issues in packaging. Even during the pandemic?

George Valiotis, CEO of glass recycler PACE Glass, thinks so.

He is predicting an uptick in sustainable practices like recycling because more people are working from home. People are consuming more materials there now, so Valiotis anticipates curbside recycling will increase by 30% to 40%.

Want to know what other consumer behavior has been affected? In a March 18 survey, L.E.K. Consulting heard from about 2,600 Americans on what they think about the outbreak’s severity and effect on the economy. Respondents also reveal what it’s meant so far for their work, leisure activities, and spending priorities. Bottom line? US consumers expect hard times ahead financially for a while.

Meanwhile … across the pond in Europe, the prognosis about recycling is quite different.

In the Waste Management World article “European Markets for Recycled Materials React in the Face of Coronavirus,” senior editors Mark Victory and Matt Tudball for Recycling at Independent Commodity Intelligence Services (ICIS), see the European recycling markets “reeling” because of the COVID-19 pandemic. They say that staff shortages may limit the ability of smaller recyclers to manage cash flow if they are unable to operate for a while. But, they also note that, of wider concern, is the impact on getting materials to and from recyclers because several countries across Europe have closed their borders, restricting the movement of goods and people. Of course, the situation in Europe is highly fluid, so we’ll have to wait to see what transpires.

Brands refit packaging lines to produce needed supplies.

To combat the spread of COVID-19, breweries, distillers, and others changeover to package sanitizers to supplement inadequate supplies. Major brands Pernod Ricard and Paris-based luxury goods company LVMH, as well as several other brands, have stepped up. Read our March 24 article here.

Since then, we’ve heard from Cardinal Spirits, a craft distillery in Bloomington, Indiana. The company’s director of communications, Erica Sagon, tells us that its hand sanitizer operations have gone “from side hustle to full time. By the end of the week, we’ll have made 5,000 gallons of hand sanitizer, much of which we’ve donated. And by early next week, 5,000 gallons more.”

Global leader in compounding pharmaceutical production and an 503B FDA-registered outsourcing firm with cleanroom production facilities, Qualgen is producing hand sanitizer — in 16-ounce, 32-ounce, gallon options, and larger-batch forms for tote tanks — as well as saline, dextrose, and common-mix intravenous solutions (IVs), as well as some other key pharmaceuticals, for home health and hospitals.

Packaging industry groups pledge support.

• The International Packaging Press Organisation (IPPO) compiles packaging-related coronavirus content from its global members, editors and freelancers who write about packaging.

• The Flexible Packaging Association asks for clarity regarding federal, state, and local government proclamations distinguishing “essential” business operations from mass population event limitations. According to the association, “FPA and its members are vital to the supply chain when addressing the needs of U.S. consumers in responding to the COVID-19 crisis. It is of fundamental importance that the industry’s manufacturing facilities stay open and functioning in order to supply the necessary packaging consumer product companies and retailers need to supply goods the public needs through this health crisis.”

• From PMMI president/CEO Jim Pittas: “At this time, EXPO PACK México, Annual Meeting and PACK EXPO International and Healthcare Packaging EXPO remain scheduled to take place as planned. …This is a difficult time, but we will get through it. Our customers – and ultimately, consumers – rely on our industry now more than ever, and we will not let them down. PMMI is here with you and for you. We will get through this crisis together, stronger than before.”

• AMERIPEN’s COVID-19 resource section offers fact-based resources about how the packaging industry is working to protect all of us and the value packaging can bring in the fight against novel coronavirus.

• The Tag and Label Manufacturers Institute (TLMI) petitions government to recognize the industry and its members as “essential business operations.”

• PAC Packaging Consortium asks the Canadian Federal and Provincial Governments to designate the packaging supply chain an essential service.

• The Plastics Industry Association (PLASTICS) President/CEO Tony Radoszewski requests all local, state, and federal governments to include plastic resin and plastic product manufacturers as “essential.”

Radoszewski also petitions the Department of Health and Human Services to investigate and make a public statement on the health and safety benefits seen in single-use plastics, including packaging.

Not everyone agrees, though. International campaign group A Plastic Planet co-founder Sian Sutherland tells Packaging Digest, “This is classic example of shocking opportunism from the plastics lobby, aka the fossil fuel industry. They want to use an international health crisis as an excuse to water down plastic bans, which are vital in the fight to save nature from the global waste crisis.” And Miriam Gordon, program director of Upstream Solutions, says in her blog “Plastics Industry Exploits Coronavirus to Prop up Single-Use Plastics,” “We are appalled that the plastics industry is using the American people’s fears about the coronavirus to push for making more single-use plastic.”

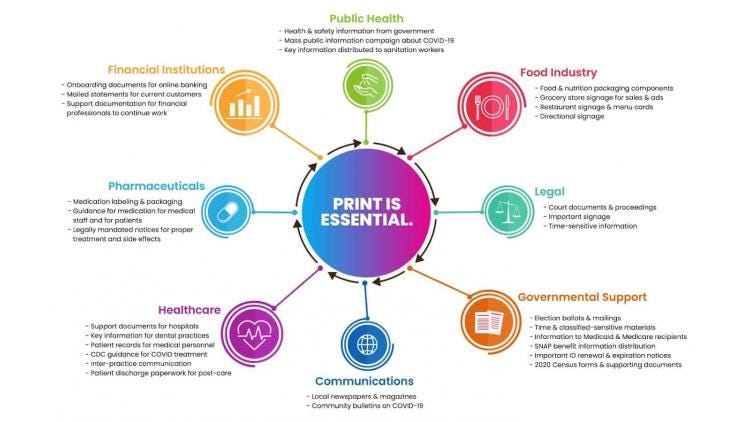

• America’s Midwest is a hub for package printing. On March 27, Printing Industry Midwest (PIM) implored Minnesota’s Governor Walz to reverse his categorization of print- and paper-related industries as Non-Essential Businesses.

Photo courtesy of Printing Industry Midwest (PIM).

• EUROPEN, the European Organisation for Packaging and the Environment, petitions the European Commission, to maintain the necessary supply of food and hygiene products, as well as medicines, to citizens throughout Europe during the COVID-19 pandemic. With many countries closing their borders, some deliveries of packaged products and packaging materials have been delayed or disrupted. The organization asks, “To guarantee the continued uninterrupted flow of (packaged) goods, the Commission needs to recognize packaging and its raw materials as essential and to open the designated priority lanes, the ‘green lanes’ for their intra-EU transport.”

• The Robotic Industries Association publishes “A3 Special Report: How Robots and Automation are Fighting Covid-19,” which outlines “how robots and automation are playing a critical role in helping to safeguard people and process the supplies that humans need as they shift to remote working and home learning.”

Packaging suppliers stay on the job to fulfill your needs.

Here are just some of the packaging suppliers that have announced their support, especially for customers in essential businesses:

• SencorpWhite modifies thermoforming machines to form face masks for medical professionals combating COVID-19.

Photo courtesy of SencorpWhite.

• TPH Global Solutions, a Chicago-based retail packaging, display and supply chain company, along with its Chicago-area manufacturing partners — Dordan Manufacturing, Mercury Plastics Inc., Adams Foam & Rubber, Assemblers Inc., and Petra & Holum — are collaborating to manufacture up to 500,000 plastic face shields by the end of April for frontline medical personnel in the coronavirus effort. The companies expect to ramp up production for up to 2 million face shields within the next 60 days, according to David Schmidt, president and chief operating officer of TPH.

Photo courtesy of TPH.

• Plastic packaging manufacturer Placon is also scaling up production in two of its manufacturing facilities to help get plastic personal protective equipment (PPE) to healthcare workers.

Photo courtesy of Prent.

• And plastic thermoforming company Prent has already designed, produced, and donated plastic face shields to medical workers — all done in just 48 hours. It will continue to dedicate an entire production line to making the face shields for hospitals across the country as long as needed.

Photo courtesy of Polar Leasing.

• For critical products in the cold chain, Polar Leasing offers 24/7 backup refrigeration during COVID-19 crisis. Bart Tippmann, president of Polar Leasing, says, “Polar Leasing has prioritized an additional 300 new walk-in refrigerator and freezer units from our manufacturer Polar King International to meet the high demand for both short- and long-term rentals in healthcare, supermarket, and government facilities across the United States and Canada. We now have expanded beyond 80 distribution depots across the United States and in some cases can deliver orders within 24 hours.”

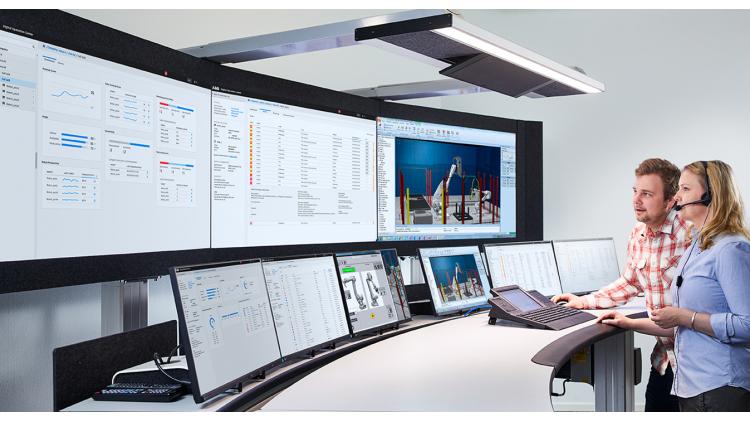

• To help customers and partners keep production lines going and to enable businesses to continue to function while many are working from home, ABB’s Robotics & Discrete Automation business is offering key software services free of charge to its customers until December 31, 2020. Among the services included are condition monitoring and diagnostics, asset management software and remote troubleshooting and monitoring of production lines for the delivery of important supplies.

Photo courtesy of ABB.

• A real-time COVID-19 dashboard on the website of international beauty packaging manufacturer and provider Quadpack helps keep stakeholders informed of the effects of the virus on the company’s global operations.

• C-P Flexible Packaging has introduced virtual press check capabilities for customers in critical infrastructure industries, allowing them to approve packaging graphics remotely using sophisticated light booths, 4K webcam equipment, and secure videoconferencing software.

• Keyence Corporation of America is also providing customers virtual demos of its equipment — sensors, measuring systems, laser markers, microscopes, and machine vision systems.

• Suppliers telling Packaging Digest they remain open to support their customers, especially those working in “essential” industries, include:

Enercon, manufacturer of induction cap sealers and corona, plasma, flame, and ozone surface treating systems.

Flexicon, manufacturer of bulk bag and drum packaging machines and conveyors.

INX International Ink Co., manufacturer of inks and coatings for commercial, packaging, and digital print applications.

Box Latch Products, maker of reusable box closures.

The Packaging Lab, supplier of custom printed pouches and film in 24 hours using digital printing and highly automated workflow.

Yupo, manufacturer of premium synthetic substrates for packaging and labels.

The nation’s supply chain is delivering.

Distribution packaging is working hard to ensure timely delivery of vital packaged goods.

While direct-to-consumer deliveries are helping supply us without having to leave the house, the vast majority of materials in America still move by pallet load, and mainly by truck.

The American Transportation Research Institute uses real-time Global Positioning System (GPS) to track freight flows. Analysis of recent data shows that “Trucks are continuing to move — in many cases faster than usual — to respond to the demands placed on the industry by the COVID-19 pandemic.”

In a press release, the association said the results can be explained by several COVID-19 related factors: First is the dramatic reduction in commuter traffic, allowing trucks to operate at higher speeds, particularly during traditional rush hours. Second, is the continuous 24/7 truck operations that generate higher average truck speeds across nearly all hours of the day.

The American Trucking Association’s president and CEO Chris Spear said in the same press release, “Normally, ATRI’s bottleneck data is used to show us where the problems are on our highway system, but during this period of extreme uncertainty, the data is showing us where the solution is — in the back of America’s trucks as professional drivers continue to quickly and safely deliver life-sustaining medical supplies, food, fuel and other essentials to Americans when they need it most.”

Well said.

On a personal note …

Former Packaging Digest senior editor and frequent freelance writer Jenni Spinner gained some notoriety in The New York Times for helping to keep her Chicago-area community connected through singalongs. She chose “Livin’ on a Prayer” by Bon Jovi as their first song.

According to the Times, “Jon Bon Jovi expressed his support in an Instagram post.” How cool is that?!

About the Author(s)

You May Also Like