Sign up for the Packaging Digest News & Insights newsletter.

2 Min Read

crave

crave

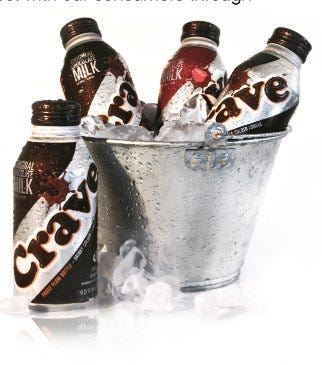

Upstate Niagara Co-op. launches Crave chocolate milk in an aluminum Frost Flow milk bottle that chills fast and stays colder, longer. Busy families can benefit from the fact that the bottle’s twist-off cap reseals, making Crave a portable and healthy snack. And because of the pasteurization process, Crave is shelf-stable. It can be stored and shipped at room temperature just like soda or juice, making it an instant hit with national retail buyers across the country. The graphics are printed directly on the cans, which are supplied by Universal Can, Japan. The caps are supplied by NCC Japan Crown Cork Co. Ltd (www.ncc-caps.co.jp/english).Crave uses social media tactics and pop-up experiential events that Upstate Niagara calls “Craves,” to engage consumers in unexpected ways. This was apparent when Upstate Niagara took advantage of the “Harry Potter and the Deathly Hallows” movie premier on Nov. 19, 2010, to create a unique product launch on the University of Nebraska Lincoln campus. Students who sampled the product were given activation cards encouraging them to become fans of Crave on Facebook. The first 125 students who became fans and posted a secret code to the Crave Facebook page won two free tickets to an exclusive midnight showing of “Harry Potter and the Deathly Hallows” at a local theater.

“The UNL Crave event was a huge success

for us,” says Ken Voelker, director of marketing for Upstate Niagara Co-op. “More than 500 students were

introduced to Crave during four hours of on-campus sampling, and we were able to give 250 of them an awesome experience with the Harry Potter premiere. It’s our aim to really connect with our consumers through events like these.”

Crave is the creation of Upstate Niagara Co-op. Inc., a group of dairy farmers in western New York. It is run at O-AT-KA Milk Products, Batavia, NY. Upstate Niagara is the majority owner of O-AT-KA.

About the Author(s)

You May Also Like