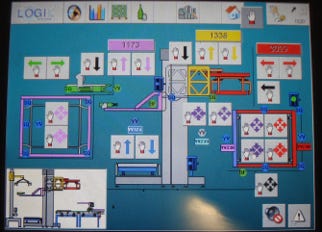

Kendall-Jackson Wine Estates, Santa Rosa, CA, totally

rrrrr1 - depalletizer.jpg

revamped its bottling operations recently with a switch to bulk glass receiving and the redesign of the two bottling lines in its plant. Both lines run 750-mL bottles, and Line 1 also fills 375-mL bottles. Running at speeds from 180 to 240 bottles/min, the lines are now among the most automated in the wine industry.

One of the key motivators of the project was Kendall-Jackson's interest in converting to bulk glass. Kendall-Jackson had always received its wine bottles in reshippers, but these have numerous disadvantages. Depalletizing cases of glass is a labor-intensive process that can cause injuries and damage cases and partitions.

In comparison, bulk glass has significant cost savings. Tom Barnes, Kendall-Jackson's director of botling, says, "The new bulk glass lines allow us to reduce our transportation costs. Bulk glass allows us to haul between 2,600 and 3,000 cases of empty glass vs 2,300 cases of glass in shipping cases." He explained bulk bottles on pallets allows vendors to store less glass because they don't have to store bottles in cases designated for a specific type of wine.

Barnes had met Emmeti USA at a packaging show and was impressed with its presentation. Emmeti was also installing bulk depalletizers in Owens-Illinois and Verallia glass plants, which supply glass to Kendall-Jackson, so he invited Emmeti representatives to explore the benefits of receiving bottles in bulk.

Kendall-Jackson decided to upgrade its existing bottling lines as part of the project, and Emmeti offered turnkey design and installation proposals. It was awarded the project based on the amount of equipment it was providing and its line design and controls.

This turned out to be a prudent decision. Barnes says, "We are very pleased with Emmeti's commitment to make the project a success. Emmeti worked very closely with us on design. Its team of installers worked very long hours to install the equipment in a small time window. The Emmeti engineers stayed on site and fine tuned the equipment to achieve the 90 percent efficiency guaranteed in the contract."

SYSTEM INTEGRATOR

Emmeti became system integrator for the project and provided engineering, design and implementation.

To start the process, Emmeti developed a line layout that reused as much of the existing conveyors as possible. This allowed Kendall-Jackson to benefit from new lines, while still using selected pieces of conveyor and some of its other existing machines, thus reducing project costs, while incorporating advanced technology to run at high efficiency.

New conveyors for the project wer

rrrr8 - depal - tier.jpg

e supplied by Emmeti's sister company, Sipac. All of the bottle conveyors, including the reused sections, are equipped with a dry lube system that minimizes friction. It eliminates the use of soap and water, which means less mess and clean up.

Emmeti also supplied much of the other new equipment installed on the lines, including the bulk depalletizers, automatic case packers, continuous bottle dividers for the packers and the bottle accumulators after the fillers. All conveyors and other equipment supplied by Emmeti to Kendall-Jackson use high-efficiency motors that conform to Eff 1 standards set by the European Committee of Manufacturers of Electrical Machines and Power systems (CEMEP), thus reducing energy usage of the line.

Emmeti's on-site technicians worked with Kendall-Jackson's staff to remove all of the existing equipment and then reinstalled the complete new lines. This included electrical and mechanical installation of the equipment, as well as electrical control integration in the bottling line panels. Emmeti also wrote the software to control all the equipment on both lines, including its own equipment as well as existing Kendall-Jackson equipment and equipment supplied by others.

BULK DEPALLETIZERS

Kendall-Jackson installed Emmeti's Lobster model depalletizers on both bottling lines. Pallets of bottles, which are supplied by O-I and Saint-Gobain North America, are delivered to the depalletizer infeed by forktruck and are placed on the infeed conveyors, where workers remove plastic covering the bottles and restraining straps.

The pallets are raised to the upper discharge platform where the machine transfers bottles, one layer at a time, to the receiving table. The Lobster depalletizers remove most of the bottles at the winery using a sweep-type head. For reverse-tapered bottles, or bottles that should not have shoulder-to-shoulder contact, the depalletizers pick up the bottles with inflatable tubes and place them on the discharge conveyor. The depalletizers can handle 2.5 layers of glass per min.

Four electro-pneumatically actuated guides square each layer as it transfers onto the receiving table. A set of clamps holds the tier sheet during the layer transfer. An independent layer-centering device holds the layer below the one being transferred to guarantee stability of the pallet during the sweeping operation.

Vacuum cups-actuated by gear motors controlled by variable freque

rrrr6 - depal diagram.jpg

ncy drives and encoders-remove the tier sheet and dunnage after each layer has been transferred and place them in magazines for later retrieval by a forktruck driver. The system will also pick up the empty pallet after all the bottles have been removed and move it to a magazine.

The Emmeti depalletizers are designed to recall any pallet pattern programmed and stored in the touchscreen operator console. Kendall-Jackson receives some of its bulk bottles inside dividers and/or partitions, and Emmeti's pick-and-place head is designed to receive and remove these bottles from inside the dividers, after which the head picks up the dividers and moves them into the appropriate dunnage magazine.

Depalletized bottles are single-filed and are then picked up by their necks for tramsport to the fillers. Emmeti's variable-speed conveyors minimize back pressure to reduce bottle scratching or tipping and ensure a smooth transition from mass flow to single file.

CLEANER/FILLER/CORKER IN AN ENCLOSURE

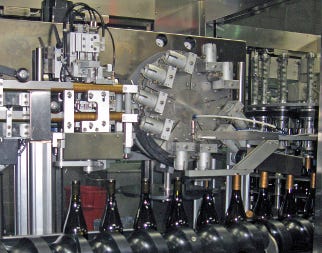

Kendall-Jackson installed a new cleaner/filler/corker from Gruppo Bertolaso S.p.a. on Line 1 and used an existing Krones Inc. cleaner and existing filler/co

rrrr2 - cleaner.jpg

rker from Gruppo Bertolaso on Line 2. In both cases, the units are housed in an enclosure.

A continuous conveyor transports the bottles through the enclosure and bottles are diverted from it at each machine and back onto it at the exit of each machine. Gruppo Bertolaso is represented in the U.S. by ColloPack Solutions LLC, which worked closely with Kendall-Jackson as the project progressed.

The new multi-head cleaner, 60-head filler and six-head corker on Line 1 are individually driven by servo drives that electrically synchronize the machines for smooth bottle handling. Each machine has a feed screw and starwheel infeed and an exit starwheel.

As bottles enter the rinser, grippers pick them up and invert them over nozzles that

rrrr3-filler.jpg

enter the bottles and inject air to remove foreign materials. As the turret rotates, the nozzles retract and then re-enter the bottles and inert gas is injected. This double injection process minimizes the presence of air in the bottles during filling.

The bottles are rotated back into an upright position as they approach the cleaner discharge and exit the machine onto the conveyor. The discharge starwheel is fitted with a safety device that stops the rinser in case a jam occurs.

Next, the bottles enter a 60-valve low-vacuum/gravity filler. In this process, the starwheel places the entering bottles onto individual bottle pedestals that rise as the machine rotates and push the bottles up against the fill valves. The fill spout enters the bottle and a vacuum is drawn to remove gas and any residual air that might be present. As the turret continues to rotate, the vacuum valve closes, and the fill valve opens and admits the wine.

As a bottle nears the discharge, the pedestal descends, allowing the fill valve to close. Bottles discharge through the starwheel.

Bottles then travel to the corker. Kendall-Jackson uses corks on all 750-mL bottles. All red wines have natural corks, while white wines will use natural and synthetic corks. All 375-mL bottles have screw caps.

As the bottles enter the corker, they again are placed on individual pedestals that lift them against fittings, where they go through a three-step process. A vacuum is drawn, followed by inert gas injection, followed by another vacuum application. According to Collopack, this minimizes residual oxygen.

Corks are inserted into the bottles after the second vacuum application. The corks travel down a channel to the application head, where they enter the unit's compressor jaws and are pushed into the bottles. After the corks are inserted, the bottles discharge through the starwheel and exit the enclosure.

The 375-mL bottles bypass t

rrrr4-capsule rotary.jpg

he corker, exit the enclosure and travel through an existing Fowler Products Co. LLC screw capper. The plant was running 750-ml bottles during PD's vist, so the screw capper was not in operation.Bottles travel to an accumulation table supplied by Emmeti that provides three min. of accumulation time should there be a problem with the capsular or down-stream labeler.

From the accumulation table, the 750-mL bottles travel to capsule applicators. The 375-mL bottles bypass the capsulars.

Line 1 uses an older in-line model manufactured by Robino & Galandrino, while Line 2 is running the newer Gruppo Bertolaso rotary capsule applicator in which the capsules are applied by a 10-head vertically rotating turret. The heads are arranged in pairs that apply two capsules simultaneously to bottles passing on the conveyor below. The capsules are delivered to the head in two parallel horizontal troughs and me

rrrr5 - capsule crimp.jpg

chanical fingers separate them as they approach the turret. Grippers then grasp two capsules and place them onto the two heads. The turret continues rotating and air blows the capsules onto the bottles.

The bottles then enter the 18-head horizontal turret that spins the capsules, without wrinkles or creases, tightly against the bottles. Each spinner has eight rollers that rotate to smooth the capsules around the bottles.

The capsules are an aluminum/poly/aluminum laminate supplied by Maverick Enterprises Inc.

A photo eye inspects the bottles as they leave the turret to ensure that the capsules are applied properly, and rejected bottles are gently pushed onto a take-away conveyor. The bottles on both lines then have front and back pressure-sensitive labels applied by Krones Inc. Autocol labelers.

Bottles leaving the labeler on Line 1 pass through a CI Vision system from Mettler Toledo that detects bottles with labels that are skewed, torn or improperly oriented. Bottles on Line 2 go through a Filtec inspection system from Industrial Dynamics Co. Ltd.

PARTITIONS INSERTED AFTER BOTTLES ARE PACKED

From the labelers, the bottles travel through continuous dividers that separate them into three lanes entering the case packer. Line 1 has a unit supplied by Emmeti, while Line 2 uses an older existing Krones separator.

Both lines are equipped with new

rrrr7 - caser - head.jpg

Emmeti model Eagle 10/3 case packers. Cases are erected by a machine supplied by *Bortolin Kemo S.p.a., which is also represented by ColloPack Solutions, and are delivered to the packers on conveyors.

As the three lanes of bottles enter the case packer, fingers check to ensure that the bottles in the pick-up zone are positioned correctly and to determine if any bottles have fallen. If a fallen bottle is detected, the machine automatically stops.

The case packer loads three cases at a time. After 36 bottles enter the pick-up zone, a bar holds back the incoming bottles to avoid back pressure on the bottles during the pick-up cycle. The system eliminates any contact between bottles and guides, thus avoiding any bottle and label damage after the pick-up.

The Kendall-Jackson packers have three gripping heads tha

rrrr9 - caser - machine.jpg

t pick up 36 bottles at each cycle and swing over and lower them into the cartons. The Eagle case packers can be set up to accommodate a range of products using gripping, magnetic or vacuum pick-up systems. The units at Kendall-Jackson use 36 chambers that inflate during the pick-up cycle and deflate after the bottles are positioned inside the cartons. Emmeti calls these inflatable heads "tulips."

A case centering device in the case packer ensures that it is positioned correctly to receive the bottles and a sensor detects the presence of the case. If a case is missing or not properly positioned, the machine automatically stops. Additional sensors allow the machine to restart only when the right number of cases are in position and stop the machine if a jams occurs outside of the case packer.

The packers are equipped with touchscreen HMIs for quick product changes, setup and access to the diagnostics. An operator can change products in less than five minutes with no tools and no manual adjustments. The bottle speed can be adjusted with a three-speed selector pick-up arm, depending on the size and rate of the bottles.

Low maintenance is standard with Emmeti's self-lubrication guides and supports. Grease cartridges that last for about two years provide automatic greasing of linear guides.

A unique feature of the case packers at Kendall-Jackson is that the partitions are inserted after the bottles have been placed in the cases. This eliminates label scuffing that occurs when bottles are packed into cases that contain partitions.

Partitions are inserted by a machine from Bortolin Kemo S.p.a The chipboard partitions are c

rrrrr11-layout.jpg

ontained in a magazine on the machine, and vacuum cups extract one partition at a time and open it when a case enters the machine. An arm extends and places the partition over the bottles in the case, after which the case conveyor vibrates to settle the partition completely.

Kendall-Jackson is currently using full-height partitions to impart extra stacking strength, but the system can also insert shorter partitions if desired.

As the cases leave the partition inserters, *Markem-Imaje Model 5000 inkjet printers apply date codes and lot information. The cases then travel over Mettler Toledo Micromate checkweighers that essentially make sure each case contains the correct number of bottles. The cases are transported up a spiral conveyor from Emmeti and are conveyed to the palletizers.

Bortolin Kemo S.p.a, +39-0434-922010. www.bortolinkemo.com

ColloPack Solutions LLC, 707-258-3940. www.collopack.com

Emmeti USA, 813-490-6252. www.emmetiusa.com

Fowler Products Co. LLC, div. of Pro Mach, 877-549-3301. www.fowlerproducts.com

Gruppo Bertolaso, S.p.a., +39-0442-450111, www.bertolaso.com

Industrial Dynamics Co. Ltd., 310-325-5633. www.filtec.com

Krones Inc., 414-409-4000. www.kronesusa.com

Markem-Imaje, 866-263-4644. www.markem-imaje.com

Maverick Enterprises Inc., 707-463-5591. www.maverickcaps.com

Mettler Toledo, 614-438-4511. www.us.mt.com

O-I, 567-336-5000. www.o-i.com

Robino & Galandrino S.p.a., +39-0141-821411. www.robinoegalandrino.it

Saint-Gobain North America, 610-341-7000. www.saint-gobain-northamerica.com

Verallia North America, 707-437-8700. www.us.verallia.com

About the Author(s)

You May Also Like