July 27, 2015

An exclusive survey provides an overview to the market status, forecast, advice and points to several unusual projects in the packaging market.

Exclusive survey results for packaging’s role in 3D printing indicates that while current activity in 3D printing for packaging is limited, that will change due to increased investment in the technology as a near-term tipping point that will bring many more companies into using 3D printing for packaging.

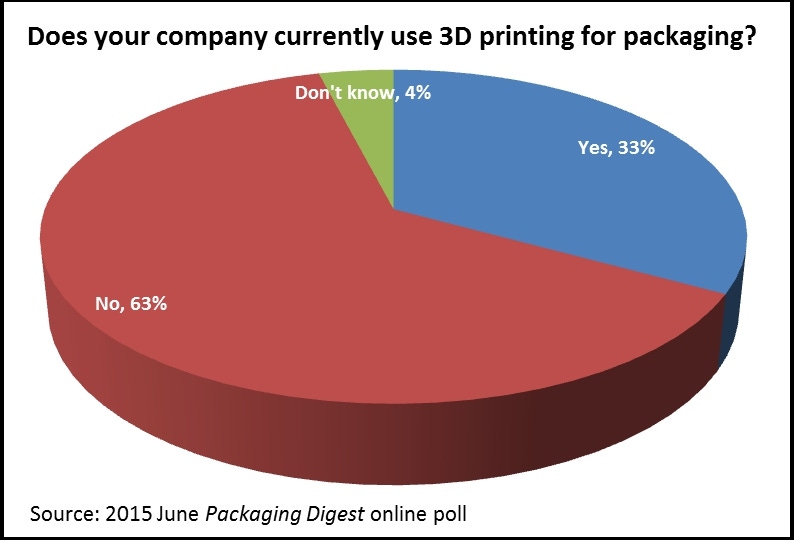

That’s according to the final results of Packaging Digest’s informal 3D printing poll answered by dozens of industry professionals. We asked for their input whether or not they used the technology because we wanted to know the reasoning for those who don’t.

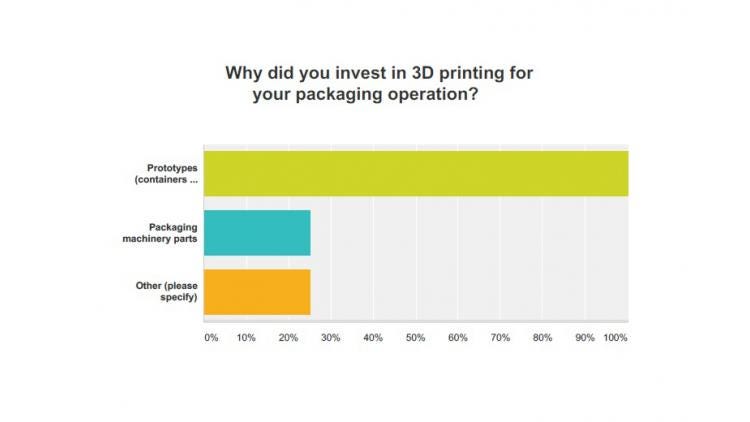

We’ll start with the reasoning for those who use the technology, which was exactly one-third (33.3%) of our poll takers, according to the poll. What do they use it for? In a question that allowed multiple responses, all (100%) reported that they use 3D printing for prototyping. Also, 25% said they use it for packaging machinery parts and another 25% said they use it for “other” purposes. We’ve bundled some of those along with justification the poll-takers indicated for why they use 3D printing:

It is very valuable—an item in someone's hands that I am designing is better than a picture.

It provides rapid, iterative design free from current machine constraints.

It can speed up prototype lead-time, it can help avoid costly dies that may have to be created even just for a prototype initially. It also gets one to a high level of accuracy.

Speed and initial low cost to generate complex designs for consumer feasibility.

It provides fast, accurate prototypes that provide good feedback for all internal customers when developing new packaging or modifying the current packaging.

It offers rapid prototypes without tooling costs.

We use it for rapid tooling development for deep embossing and debossing applications.

It’s another important tool in the toolbox. Rather than use a CNC, milling machine or lathe, a 3D printer gives you another way to output a concept or idea to support the packaging innovation process.

It’s an excellent way to provide unique solutions to customers.

It is very useful for mockup preparation.

We use it for components and machinery parts.

Enables us to quickly innovate and respond to our customers.

The high value to see the advantages and disadvantages in the printed design

We don't do it internally, we leverage our suppliers and their outsource partners, mostly for prototyping packaging components.

There are too many advantages to list.

We found that exactly one-third (33.3%) who use the technology do the 3D printing in-house; more than one-fourth (26.7%) outsource the technology and 40.0% use a combination of self and contracted projects.

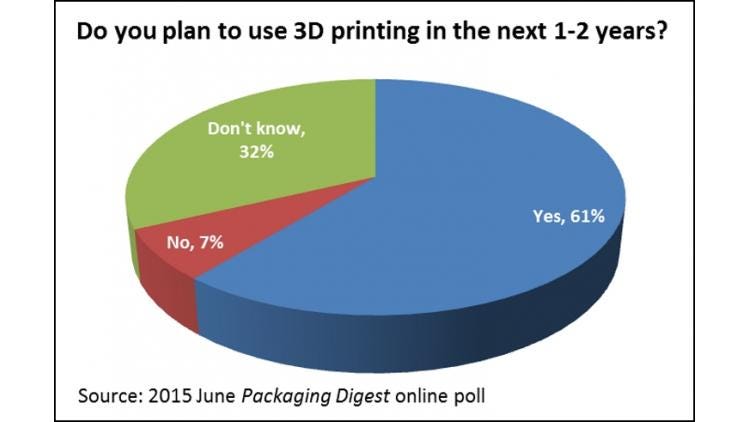

Next we explored the reasoning for nonusers and peered ahead at 3D printing's near-term future in packaging…

We found that the majority of respondents (~63%) don’t use 3D printing technology; of those, 44.4% reported that it was not applicable to their business while another nearly 30% reported that it was not in the budget. Examples of “other” responses that comprised 26%: we don't know how best to utilize 3D for packaging; we are in a wait and see mode; we don’t need it; and we have not done any projects currently, but may explore it for the future. This response captures the essence of those caught in the middle: “There’s a huge potential, but currently the advantages in packaging are not very clear.”

It was the future exploration that we wanted to address with the question “Do you plan to use 3D printing in the next 1-2 years?” Specifically, 61.4% said Yes, 6.8% said No and 32% checked off Didn’t Know.

We also asked for advice, which elicited the following:

Be careful on how you choose a printer.

Buy 3D printers or partner with good 3D machine vendors. Also, don't be cheap!

Find a partner. Most software companies that sell CAD CAM programs also offer 3D printing

First purchase Solidworks and become competent at design. Without that capability, the 3D printer will sit idle.

Make sure your design works well with the technology.

Tailor the printer type to your application. There are many choices each, with their own nuanced differences.

The 3D printer used for prototyping must be using the print technology that provides a very smooth, production-quality surface. Not all 3D printers are alike and capable of producing production quality surfaces.

Try to use a transparent plastic. [Ed note: Presumably because this allows users to see the details of the printed object’s shape and contours.]

Interestingly, one person suggested that conductive inks can be used in a 3D printer.

Another respondent echoes a universal lament from across the spectrum of packaging about a lack of time and resources: “I wish we could learn how to use the associated software programs and hardware internally to gain a deeper knowledge of its uses and applications, but we don't have the allocated apace and resources for it.”

Among the unusual 3D printed projects that we solicited, this Elephant Bottle was certainly one of the more interesting. The 3D printed version used for prototyping is on the right.

Finally, we asked them to tell us what was the most unusual 3D printing project you’ve used related to packaging? Here's what they told us:

Parts to hold product in place within a crate;

Replicating food products for sizing studies; [Ed. note: I've known of a brand owner that arranged to have various sizes of protein products 3D printed to then determine the sizes of the packaging required for different product sizes and package counts.]

Printed a box insert for small hardware, then sent that 3D piece out for approval with a sample of the intended end use material that was a bio-based paperfoam. We gained approval right away and saved weeks of time!

Printing a piece of art and merged the art with packaging.

Created a candy tin prototype container where the skirts were shrink-wrapped with a full-color label and the top was adhesive labeled.

A 1-L bottle that has an elephant’s face (see image above).

While 3D printing’s role in packaging is currently a mixed bag, we can expect more and broader uses for the technology in the months ahead.

You May Also Like