A plastic foam packaging guideline for online and direct-to-consumer retail shipment includes the three most common polymers for packaging, PE, PP, and EPS.

Brand owners are under ever-increasing pressure from online retailers to ensure products are packaged to prevent damage, minimize shipment size, and reduce packaging waste. This year, for example, Amazon expanded its Frustration-Free Packaging Incentives Program to encourage vendors “to create and certify packaging that saves space and materials and protects products while in the ecommerce supply chain.”

In the ecommerce world where “cube is king,” plastic foam reigns as a go-to solution. The rapid rise in ecommerce during the COVID-19 pandemic and increasing packaging requirements from online retailers underscores foam’s ability to deliver a positive customer experience while protecting products, reputations, bottom lines, and the environment.

Packaging foam can take on many forms depending on a product’s value, weight, fragility, geometry, production volume and other variables. Choosing the right one is crucial to delivering the required protection.

Void fill, such as foam peanuts, is inexpensive and versatile, but the fill can migrate and shift to the bottom of the box during shipping, losing its protective function and increasing breakage risk. The potential for a negative consumer experience is compounded by the fill often ending up on counters or floors or clinging to other surfaces. This form is losing favor and is more typically used with low-cost products that have minimal fragility.

Molded foam, which as the name implies is custom manufactured to fit the product it protects, is designed to cushion in the most effective manner, minimizing waste and reducing the overall volume of the package. The package designer chooses an appropriate polymer in a specific density to deliver the required protection. Through a series of tests and design iterations, the molded foam is optimized to deliver the most cost effective and sustainable design. This format is typically used for high-value or fragile products that have little structural variation between units and are produced in higher volumes – 10,000 units or more per year – to overcome the foam’s initial tooling cost.

Foam corners, which are a form of molded foam, are best with products that have standard configurations. Like other molded foam, corners are also most economical for high-volume products. The corners are used to protect cubic square or rectangular shaped products that have moderate fragility, most commonly cabinets, office furniture, appliances, or electronics such as desktop computers. They can easily be used in over-boxing situations where additional impact protection may be required for the last mile delivery to a consumer.

One of the most versatile foam forms is plank, which is manufactured in various thicknesses, lengths, and densities which are then cut to size and fabricated to the product or package specifications. Planks are often used for blocking and bracing or when multiple items are placed in the same shipping box. This foam form can handle a wide range of product fragilities, structural variability, and production volumes. Low-cost tooling with minimal lead times makes this an attractive solution to quickly address unexpected increases in product damage rates.

Polymer selection.

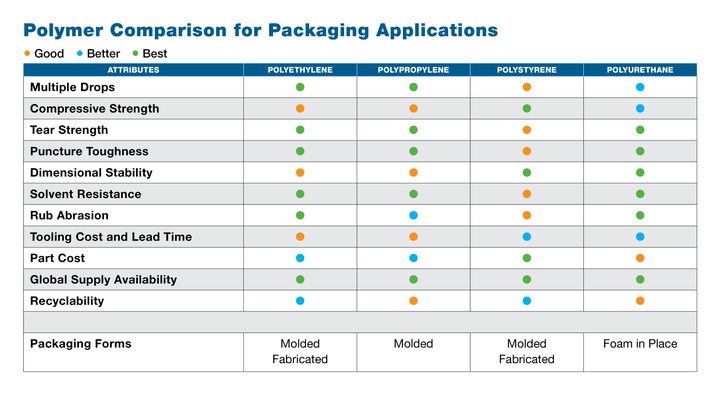

Another important consideration in packaging foam is the polymer the designer selects. The three most common polymers for packaging applications are polyethylene (PE), polypropylene (PP) and expanded polystyrene (EPS). Polyurethane (PU) is also used in foam packaging, but its higher cost makes it less desirable despite its performance, versatility, and simplicity.

Understanding the various foam forms and polymers is critical to designing an ecommerce packaging solution that will consistently meet seller and customer expectations.

Within a single polymer type, there is also usually a range of product grades that perform differently for a given application. It is critical to work closely with your resin supplier to ensure the grade you choose is best for your specific needs.

Five-star performer.

Foam packaging helps brand owners meet their circular economy goals, and the expectations of online retailers, by reducing product loss and minimizing the shipment’s environmental footprint.

Product damage can be a huge expense to etailers, not to mention how it can damage the company’s reputation and impact future online sales. Too many returns for damaged products may lead e-tailers to pull an item from their sites. The economic and environmental costs of a product that is shipped, returned, and shipped again also add up.

Two primary factors can drive the need to beef up a product’s packaging:

Product downgauging, which can increase fragility and reduce structural integrity.

The introduction of direct-to-consumer shipping, which has a more rigorous and less predictable fulfillment chain.

Foam packaging in the correct form and using a suitable polymer provides significant multi-impact resistance, helping ensure a product arrives in the same condition as when it was shipped.

Another overlooked component of ecommerce is how to protect products that are not damaged but are returned to the vendor. The durable polymer foam can be reused for the return shipment, increasing the chances that the product will not be damaged and can be resold. Without foam, customers may use inferior materials that could increase both shipping costs and the risk of product loss.

Evironmental impact reduction.

A well-designed polymer foam solution can reduce the amount of packaging required to protect a product and usually also weighs significantly less than alternative packing materials. Less packaging to wade through boosts both the customer experience and the seller’s reputation.

Foam’s inherent resiliency, which absorbs the energy from an impact or drop and then recovers to continue offering protection, enables this reduction in packaging. Other material types of secondary protective packaging can require thicker cushioning to survive multiple impacts, increasing the size of the box and packaging materials used.

Recycling remains a challenge in most geographies, mainly due to collection economics, but some locales and companies offer options including curbside, drop-off, and take-back, which is an example of closed loop recycling programs. However, foamed polymers are monomaterial and generally free from contaminants, making them excellent recycling feedstocks. More innovation and investment are essential to keep this valuable material out of landfill and instead recycled for use in new products and packaging again and again.

The takeaway: with ecommerce now firmly entrenched in the consumer landscape, the performance of a product’s packaging can be as important as the performance of the product itself. Foam is a versatile, sustainable, and cost-effective packaging solution that offers the dual benefits of multi-impact protection and a reduced environmental footprint.

Bryan Kirsten is a Technical Service Specialist at Nova Chemicals. In his role, he supports the post-consumer recycle (PCR) market with applications development work that improves the quality and value of recycled polyethylene and increases market demand. Prior to taking his current role in early 2020, Kirsten spent 20 years developing deep expertise in protective packaging design including foamed polymer applications. His experience includes work as a Packaging Engineer at Sony Electronics and SCA, and starting in 2009, as a Sales Engineer in NOVA Chemicals’ styrenics business. He holds a Bachelor of Science in Packaging from Michigan State University.

About the Author(s)

You May Also Like