Manufacturers are actively digitizing their production operations, supply systems, and customer relations.

June 16, 2021

Manufacturers are turning to digital processes big time. According to BDO’s 2021 Industry 4.0 Survey, 49% of manufacturers will fast-track digital investments this year. They will focus on improving customer experience, optimizing supply chains, and aligning their workforce with new technologies,

The survey indicates that in one year, nearly all supply chains will be digital. A hearty 87% of manufacturers have digitized – or are in the process of digitizing – their supply chains. They’re aiming to increase visibility and agility to adapt more effectively to disruption, unlock new efficiencies, and better leverage data throughout the enterprise.

The move to digital is not new, but the urgency to complete the process was accelerated during 2020. “Pre-COVID, this was already a priority. Manufacturers wanted line-of-sight in their operations. When COVID hit, customer demand shifted and manufacturers needed to get a grip on it,” Eskander Yavar, leader of BDO’s national manufacturing practice, told Design News. “They needed to have visibility on their orders. What we’re seeing in our personal lives with Amazon is going to show up in manufacturing. Manufacturing operations will start to look like consumer e-commerce operations.”

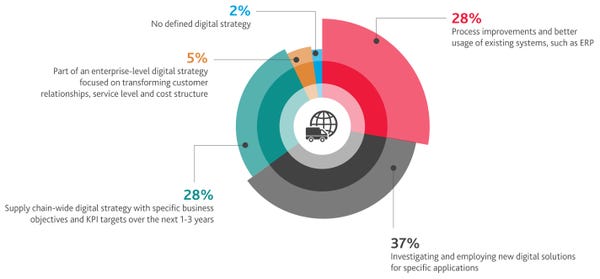

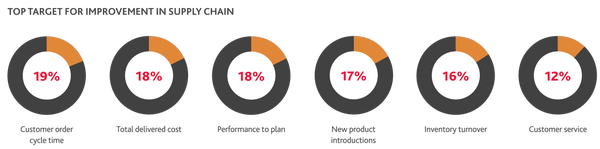

Revamping the Supply Chain

The survey indicates that manufacturing supply chains are becoming more integrated and transparent. Manufacturers are getting better at sharing their data across their business. Likewise with their customers and suppliers. The goal is to form a more holistic view of the supply chain, even for goods not directly in their control. “The data over the last several years shows that manufacturers have intended to digitize their supply chains. COVID made the process a higher priority. Nearly 95% of all supply chains have been impacted by COVID. We saw a quick shift in focus to the supply chain,” said Yavar. “Manufacturers saw the need for transparency in the supply chain and they turned to digital tools to make that happen. Because of this, supply chains are becoming more integrated and transparent.”

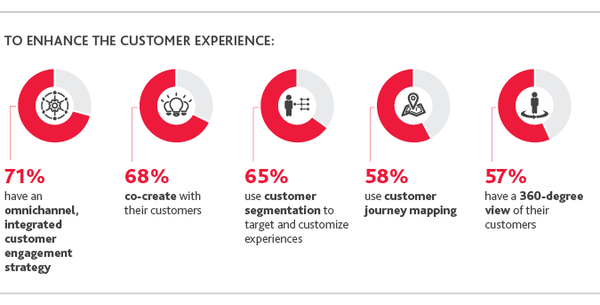

A Focus on the Customer

The survey also reveals a customer-centric transformation. Manufacturers are making changes to better serve and even collaborate with their customers. This includes deploying a cloud-based collaboration platform (63%), leveraging real-time customer intelligence (51%), and data-driven personalization (49%). “Historically things were more product-oriented. The manufacturers could make a product, and they stuck to it no matter how things were changing,” said Yavar. “The disruption was data. Manufacturers started to leverage the data and respond to customers. In the past it was, this is what I make. Now organizations are doing social crawling and looking at where the demand is going.”

Manufacturers are beginning to seek equipment that is flexible and adaptable to accommodate customers. “They are looking at what customers are seeking. As a result, they’re doing more and more customization,” said Yavar. “Not all of the equipment is ready for this. The heavy equipment can’t change quickly. But even that is changing. We’re seeing the ability to retrofit the pant equipment to lower the percentage of downtime and adapt to the customer shift.”

Data-Driven Decisions

The survey also revealed that manufacturers are harnessing data to drive decision-making. In the next year, nearly all manufacturers will be deploying cloud computing (99%), data analytics (96%), and ERP software (92%). What’s more, about a third of manufacturers are using advanced analytics, including forecasting and predictive models, and real-time reporting.

The data feed from customers is getting incorporated into marketing. “The focus on customer experience is getting parlayed into sales and forecasts,” said Yavar. “Manufacturers are making changes to inventory and adapting to customer trends.”

The digital changes are showing up in operations, supply chain technology, and customer-relations tools. “The pushed digitization to a higher priority for manufacturers. That surprised me,” said Yavar. “I didn’t expect that those in the C-suite would be affected so much that they would make the digitalization of the supply chain a high priority. Same with listening to their customers. This is different than in the past. Before we were seeing incremental changes. Now it’s monumental.”

Rob Spiegel has covered manufacturing for 19 years, 17 of them for Design News. Other topics he has covered include automation, supply chain technology, alternative energy, and cybersecurity. For 10 years, he was the owner and publisher of the food magazine Chile Pepper.

About the Author(s)

You May Also Like