March 11, 2015

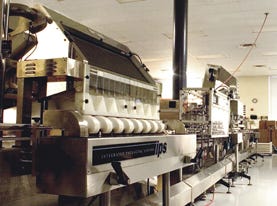

To accommodate the full line of Dr. Weil supplements, as well as its expanding private-label business, ANS installed a new packaging line that includes a slat counter, a cottoner and a desiccant inserter.

Arizona Nutritional Supplements (ANS), a leading contract manufacturer and packager of custom nutritional and dietary supplements in Chandler, AZ, recently faced some growing pains. The company was awarded a license agreement with Dr. Andrew Weil to produce a new line of vitamins bearing his name. This new business opportunity, combined with rapid growth in its client base, required ANS to increase its line speeds significantly, while at the same time maintain current Good Manufacturing Practices (cGMP).

Help arrived quickly with the installation of a new packaging line featuring desiccant-insertion equipment designed specifically for the vitamin supplement industry. Manufactured by Multisorb Technologies (www.multisorb.com), the new APA-1000 desiccant inserter turned out to be the right solution at the right time. Other equipment on the new line includes a slat counter from Integrated Packaging Systems (IPS [www.ipsnj.com]), a cottoner from Deitz Co., Inc. (www.deitzco.com), a capper from SureKap, Inc. (www.surekap.com), a pressure-sensitive labeler from So. California Packaging Equipment (www.scpe.com) and a neck bander and shrink tunnel from Axon Corp. (www.axoncorp.com).

Within two weeks of implementing the new packaging line, ANS was able to reduce its packaging shifts from two to one—a dramatic improvement that not only met ANS's immediate needs, but also gave it the capacity to grow in the future.

As the vitamin supplements market continues to grow, more nutraceutical manufacturers are adopting cGMP standards for quality assurance, and ANS is a state-of-the-art example. Founded in 1997, ANS manufactures tablets, capsules and powders at its 50,000-sq-ft facility and provides a comprehensive range of contract packaging, labeling, warehousing and worldwide shipping services.

ANS has implemented quality-assurance programs to ensure the safety and purity of all raw materials. Material analysis, visual inspection and laboratory validation are performed on all products before distribution. Complete documentation is provided according to cGMP standards, and ANS employees receive continuous training.

ANS produces more than 1,200 different formulations, vitamins, minerals and herbal supplements for more than 90 different companies, and it has the capacity to manufacture up to 150 million capsules and tablets per month. The company has grown rapidly, and managing the growth of this successful operation has been a challenge.

The license agreement with Dr. Weil represented the first time ANS would handle everything for an entire line of vitamins, including manufacturing, distribution and product marketing. While the opportunity represented a milestone for ANS, it also presented the company with a dilemma: Facing an ever-expanding client base, ANS needed to increase its line capacity on the warehouse floor and optimize its packaging efforts.

"We have tripled our size in just three years," says Kirk Neal, vp of operations at ANS. "We needed help not only in ramping up for the new product line for Dr. Weil, but also in addressing our increasing growth on the entire private-label manufacturing side."

ANS began searching for versatile equipment that could handle high speeds. "When we started looking for a new packaging line, we wanted something capable of efficiently handling production runs from 5,000 to 50,000," says Neal. "At a minimum, we needed a system that could run 120 100-count bottles per minute and could be changed over easily and quickly from one bottle size to another."

A switch to new MULTISORB SORBENT PACKS for its bottled pharmaceuticals helps Roxane Laboratories, Inc. increase packaging line speeds by 25 percent and decrease production downtime. Read more at: www.packagingdigest.com/ info/roxane

ANS worked with Jeff Grass of Equipment Technology Co. (www.equiptechco.com), an integrator who helped analyze the performance requirements for the packaging machinery and components. After a thorough search, ANS discovered Multisorb, which develops specialized sorbent technology and high-speed sorbent-insertion equipment, along with service and support.

Multisorb customizes machinery primarily for pharmaceutical customers, however the company recently launched the APA-1000, a machine similar to equipment used for high-speed pharmaceutical packaging lines, but designed to meet the requirements for nutraceutical packaging. ANS says it had found its perfect match.

Supplement bottles move through a cottoner.

The APA-1000 incorporates checkpoints to ensure positive desiccant placement in packaging and consistent packet separation from spool lines. The dispenser system provides touchscreen flexibility for multiple bottle/desiccant/line-speed configurations and can be incorporated into existing packaging lines.

"Multisorb demonstrated a real propensity to work with us," recalls Neal, adding that the company understood the special requirements of the vitamin supplement market. "We're not a pharmaceutical company, and we didn't need machinery with all the bells and whistles. We needed accuracy and high speed."

At first it was suggested that ANS use a canister-type desiccant inserter, however despite an initial savings in equipment, this option would have been more expensive in the long run, due to the higher costs of canisters versus desiccant packets. "We felt packets were the way to go since they are much more cost-effective for keeping products dry and stable," Neal says.

Neal uses 1/2-g StripPax(R) desiccants from Multisorb. The low profile and compact shape of StripPax saves space and displaces a minimum amount of product in bottles, and its flat contour eliminates confusion with pills, Multisorb notes. StripPax packets are manufactured to tight tolerances so that packet sizes and seals are consistent, resulting in accurate separation and insertion. It is formed with sonically welded, uncoated Tyvek(R) material that is designed to be nondusting and to be extremely tough and durable, according to Multisorb.

After p-s labeling, supplements are conveyed to a neck banding machine and then through a heat tunnel.

"Depending on the application and the amount of sorbent used, we've found that StripPax packets save customers between twenty and eighty percent compared to the equivalent canister size," reports Robert Sabdo, business development leader at Multisorb. In addition, Sabdo notes, canisters can sometimes jam in dispensing equipment, and canister tops can pop out, resulting in contamination on the packaging line and downtime for cleaning.

The APA-1000 can run a range of sachet sizes from 0.59 to 1.97 in. wide and 1.18 to 3.94 in. long, however ANS is currently only using continuous reels of the 1/2-g size of StripPax desiccants. "At this point we're running only one size, but the new machinery enables us to run additional sizes," says Neal.

Another factor in the decision to purchase the APA-1000 was its ability to handle quick and easy changeovers for different bottle sizes. The APA-1000 is fully automatic and inserts sachet-style desiccants at rates up to 120/min. As a result, ANS went from two shifts to one in just two weeks. This change led to a dramatic reduction in labor costs and overhead, further increasing overall efficiency.

The installation of the equipment was smooth and quick, ANS reports. Several representatives from Multisorb traveled to the ANS facility to help install the equipment, and they remained on-site following the installation to help train relevant personnel and to troubleshoot.

"The new Dr. Weil product line has nineteen formulations that make up thirty-nine stockkeeping unit numbers, so there were bound to be a few minor obstacles to overcome with the new packaging equipment," says Neal. "Multisorb's representatives were willing to stay and work with us to teach our employees about the new equipment."

The APA-1000 also integrates well with the other equipment on the line. Equipment Technology helped ANS integrate each piece of new equipment, including conveyors and air and electrical hookups. "I believe the selection of equipment chosen by ANS demonstrates a commitment to moving business to the next level," Grass notes.

"It's just been a phenomenal experience," concludes Neal. "Everyone who has seen this new machinery has been really impressed. The new line has worked out great, and it's just what we were looking for as we move our company to the next step."

More information is available:

Multisorb Technologies, 716/824-8900. www.multisorb.com.

Axon Corp., 919/772-8383. www.axoncorp.com.

Deitz Co., Inc., 732/681-0200. www.deitzco.com.

Equipment Technology Co., 310/545-4321. www.equiptechco.com.

Integrated Packaging Systems (IPS), 973/664-0020. www.ipsnj.com.

So. California Packaging Equipment, 909/598-3198. www.scpe.com.

SureKap, Inc. 770/307-4755. www.surekap.com.

You May Also Like