|

IPM Foods LLC, Beloit, WI., was founded in 2006 by president Pawel Marciniak as a contract packager utilizing the Tetra Recart carton, which was developed by Tetra Pak, Inc. (www.tetrapakusa.com). Joe Pirc joined the company in 2008 as vp of sales and marketing. In addition to installing a complete processing and packaging operation rated at 400 cartons/min, IPM also provides product development and testing services and short-run manufacturing of products for test marketing and product testing.

Tetra Recart is the world's first retortable carton packaging system designed for low-acid, shelf-stable food products with particles of almost any size. Tetra Pak supplies both the form/fill machine and the cartons. Food products, such as beans, vegetables, tomatoes, soups and sauces are cooked and sterilized inside the Tetra Recart carton with a resulting shelf life of up to 24 months.

Marciniak had been involved with the Tetra Recart technology at Tetra Pak, both in Europe and the U.S., for many years, while Pirc was in Tetra Pak's marketing department and had developed a strong background in private-label marketing. “It's a great opportunity for me to work with something I love,” says Marciniak. “The technology is just getting started here in the U.S., and it has a tremendous upside. The retort cartons can replace cans and jars and have many advantages over those containers.” One benefit is shelf appeal. The flat carton face provides a great billboard for products on the store shelf, and the rectangular shape lets three cartons fit in the same shelf space as two metal cans. There are also major shipping benefits. A pallet will hold 35,000 Tetra Recart carton blanks. Thus, one truckload of Tetra Recart cartons corresponds to approximately 15 trucks delivering empty cans or glass jars. Comparing finished product, a pallet will hold up to 50 percent more cartons than cans. From a consumer standpoint, the carton's laser-perforated, easy-open feature allows consumers to open the package with no can opener and presents no sharp edges.

|

The intermittent-motion form/fill machine handles two cartons simultaneously. Dry components discharge through funnels into the cartons, top photo. Carton blanks are pushed up onto mandrels for forming. |

IPM Foods' first commercial product is Dal Raccolto-brand Tuscan vegetable soup, which is distributed by Colavita USA. “Colavita was familiar with Tetra Pak, and when they heard about our Tetra Recart operation, they contacted us about producing the soup, which is being marketed at selected Sam's Club stores” says Pirc. “This was initially a one-shot deal, but the product has done so well, that they have extended their order.” IPM also is currently running products for a national natural-food retailer, who is launching several items in

|

Tetra Recart cartons in mid-January, and it is in discussions with several big natural-food retailers about new products for this fall. “This is an upper-scale, high-end product, so it's well suited for premium private label and natural and organic products,” says Pirc.

Carton composition critical

Although the Tetra Recart package resembles other Tetra Pak cartons, it employs a construction incorporating a proprietary six-layer paperboard, foil and polymer laminate structure that allows it to be retorted at conventional retort temperatures (up to 262 deg F for up to two hr). From inside to outside, the structure consists of PP (contacting the product), aluminum foil, PP, paperboard, PP and laquer-protected flexo-printed graphics, The structure contains 65 percent paperboard.

The highly moisture-resistant paperboard material and the proprietary polymers support the structure during retorting, while the foil and polymers provide barrier properties. The lacquer-coated and printed paperboard on foil creates a glossy, smooth surface and an eye-catching package, while the print surface resists scratching. Graphics are printed on the fiberboard using a four-color, process-printing method, described as an advanced flexo process, using proprietary, heat-resistant inks. The packaging is produced and printed by Tetra Pak at one of its production plants.

|

Liquid component is filled from a holding tank on top of the form/fill machine into the cartons by piston fillers. |

Three filling stations

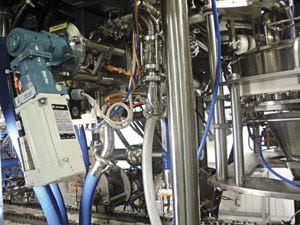

The 90,000-sq-ft Beloit plant contains two floors with processing taking place on the second floor and packaging on the first floor. IPM has installed a Model TPR2 intermittent-motion form/fill machine that runs 12.1-, 13.9- and 17.8-oz cartons at 100 cartons/min. The machine runs the cartons in-line, but handles two cartons simultaneously throughout the operation. To start the packaging operation, a worker loads the flat, premade, preprinted cartons in the infeed magazine. Suction cups remove the carton blanks, open them and push them up onto mandrels that are on a rotating turret. This carries them past induction-sealing stations, where the bottoms of the cartons are sealed shut, followed by stations where the end flaps are folded inward and then sealed in-place to form a flat bottom. The machine has eight mandrels to handle the cartons during the sealing step. Suction cups remove the cartons from the mandrels and drop them into cavities on a conveyor that transports them through the remaining operations.

The machine at IPM has three individual filling stations in succession to deposit dry, particulate and liquid components in succession. Dry components are delivered to a hopper on the top of the machine and drop through a funnel into a rotating volumetric filler with six telescoping cups that discharge through two funnels that feed two cartons at a time on the conveyor below. The quantity of product dispensed is changed by adjusting the volume of the cups. Particulate product drops from a hopper through hoses into two piston fillers that discharge into the cartons through rotary valves. Liquids are dispensed from an overhead holding tank by two piston volumetric fillers. The discharge volumes of both the particulate and liquid fillers are regulated by adjusting the length of the piston stroke. The entire filling station was supplied by Zanichelli Meccanica S.p.A. (www.zacmi.it) and was installed by Tetra Pak when it assembled the machine.

|

The plant has four retorts that hold two racks of cartons. Each rack holds 756 cartons. |

Next, the tops of the cartons are sealed in a two-step sequence. First, the tops of the cartons are induction-sealed shut. Then the sealed tops are folded down onto the tops of the cartons, after which the end flaps are folded over and induction-sealed to the sides. The amount of material extending above the top of the carton after sealing is greater than the amount extending below the carton during bottom sealing because the top contains a tear-strip for the end user to use to open the carton.

An operator panel with a touch screen shows the status of the machine, and allows the operator to change the operating parameters for different carton sizes by touching the icon on the screen.

As the sealed cartons leave the TPR2, they pass beneath the printhead of a Model A300 ink-jet printer from Domino Amjet, Inc. (www.dominoamjet.com) that serializes every package. The unit prints the product batch number, the use-by date and a unique serial number so that every package can be traced from production to end user. The ink, which is also supplied by Domino Amjet, is heat-sensitive and permanently changes color at retorting time and temperature, so IPM can be certain that the cartons were sterilized. IPM has two identical printers in tandem for redundancy. If the primary printer malfunctions for any reason, the secondary unit will immediately take over the printing operation.

|

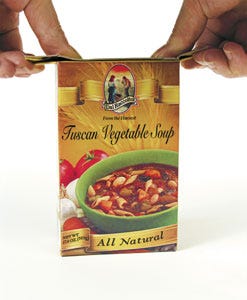

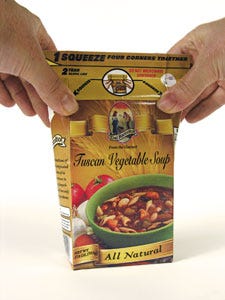

A major advantage of the retort carton is its ease of opening. The opening procedure is shown from left to right in the photos above. First, loosen the top flaps from the carton, Next, squeeze the carton to push up the top. Next, pull off the tear strip. Finally, pour out the product. |

Four retorts

From the form/fill machine, the cartons are conveyed to the retorting operation in an adjacent room. This operation starts with an automatic retort-tray loading system from Danish company Jorgensen Eng. A/S (www.jorgensen.dk). The cartons, which are standing up on the conveyor, are tipped on their sides before they enter the tray-loading system. In this operation, cartons enter the tray that is sitting on a cart. After six cartons accumulate on the tray, a lever momentarily holds back the entering cartons, while that row of cartons on the tray is pushed forward. The lever then raises, and the operation is repeated until the tray is filled with 14 rows of cartons. The lever again holds back the cartons, while the tray is raised one level and another tray is pushed into place. This process is repeated until nine trays have been filled, and the rack is holding 756 cartons. At this point, the operator pushes the rack onto a cart, another rack is placed into the loader and the operation is repeated.

The cart is wheeled to a Steam Water Spray™ batch retort from FMC Technologies (www.fmctechnolgies.com), where the cartons are sterilized. IPM has four retorts, each of which holds two racks of cartons. Once the retort is closed and sealed, hot water is circulated through the unit and sprayed onto the cartons. A combination of air and steam is also injected into the unit. The steam provides additional heating, while the air provides over pressure to prevent the cartons from expanding as the contents are heated. The sterilization temperature is about 250 deg F, and the entire heating, sterilization and cooling cycle takes about two hours. IPM places a retort check tag from Steritec Products Mfg., Inc. (www.steritecproducts.com) on each rack of cartons before it enters the retort. The tag changes color from purple to green after a set time and temperature, and it provides a visual validation that the rack has, in fact, gone through the sterilization process. “This is not to check that the product is sterile,” says Marciniak. “We have very rigorous quality assurances to ensure that. These tags make sure that a rack has gone through the retort and eliminates the

|

Particulate product drops from a hopper through hoses into two piston fillers that discharge into the cartons through rotary valves. Liquids are dispensed from an overhead holding tank by two piston volumetric fillers, top photo. Particulate and liquid fillers are servo driven. |

|

possibility, however slight, that it might be delivered in error to the tray unloader.”

After the racks are removed from the retort, the operator loads them onto a cart and takes them to a detraying operation that is the reverse of the loading operation. From there, the cartons are delivered to a Tetra Pak Model 70 wraparound tray packer. The packages are grouped into either a 2x6 or a 2x8 pattern, after which they are moved onto a tray blank of corrugated board. The blank is shaped around the packages and glued with hot-melt adhesive on a unit from Nordson Corp. (www.nordsen.com). The trays then are conveyed to a Tetra Pak Model 51 shrink wrapper.

The Tetra Recart package has found wide acceptance in Europe, but has had little exposure in the U.S. With its many sustainability attributes, it seems to be the ideal package at the opportune time. However, its uniqueness and the technical complexity of the technology present an educational challenge to companies that might be interested in adopting it. Now, with IPM Foods available to provide consulting services and short-run production as well as extended product runs, more products in Recart cartons should be appearing in the U.S. very soon.

More information is available: |

Tetra Pak, Inc. 847/955-6000. www.tetrapakusa.com. |

Domino Amjet, Inc., 847/244-2501. www.dominoamjet.com. |

FMC Technologies, 281/591-4000. www.fmctechnologies.com. |

Jorgensen Eng. A/S, 45 63 13 22 11. www.jorgensen.dk. |

Nordson Corp., 770/497-3700. www.nordsen.com. |

Steritec Products Mfg., Inc., 303/660-4201. www.steritecproducts.com. |

Zanichelli Meccanica S.p.A., 39 0521 490211. www.zacmi.it. |

About the Author(s)

You May Also Like