January 30, 2014

|

Every autumn, fruit attached to long-running vines in bogs and marshes throughout North America deepen into an intense red. This coloring signals to the fruit growers, which supply Ocean Spray Cranberries, Inc., that the berries have reached the peak of flavor and are ready for harvesting.

The majority of these berries are harvested using a dramatic, multi-day, wet-harvesting process that begins when a grower floods a cranberry field with up to 18 in. of water. The second day of harvesting begins with water wheels separating the deep, red fruit from its tethers below the water's surface. Once freed, the berries, propelled by the pockets of air contained in them, crest the water's surface. The growers manually corral the bright floating fruit before it is conveyed out of the bog and truck it to Ocean Spray's processing facilities, where the berries are used to make a variety of products including juice drinks, cranberry sauce and increasingly sweetened, dried cranberries.

Sweet treats

Many consumers know sweetened dried cranberries simply by the Ocean Spray brand name, Craisins®. The company engineers prefer to use the more precise term, sweetened dried cranberries, or its initialism, SDC.

|

At its production facilities in Middleboro, MA, Ocean Spray uses a patented technology to sort, slice, process and dry the cranberries into SDCs. The SDC operation runs seven days a week, 24 hours a day. The facility packages the product into several different package forms, including 6-, 12- and 48-oz pouches for retail, mass-merchandise and clubstores. Beginning September 2008, the Middleboro plant also started filling a multipack containing six 100-calorie pre-portioned pouches of Craisins®

While SDCs often appear as ingredients in modern cooks' and bakers' recipes, the fruit also is consumed as a standalone snack. “Consumer research has shown that the number-one consumer usage occasion for the Craisins® brand is snacking,” says Courtney Genovese, associate marketing manager—foods, Ocean Spray.

In response to consumer demand for SDCs for standalone consumption as well as the popularity of portion-controlled snacks, Ocean Spray embarked on a more-than-year-long process to create a high-speed, precision filling and packaging line for the sticky fruit.

The packaging-line project was developed and implemented using a team concept. Representatives from Ocean Spray's marketing, research and development, engineering, operations, finance, manufacturing, sales and graphic design departments all contributed to making the Craisins project successful.

Sticky situation

Working with a bevy of suppliers, the team set the project's first challenge. “We challenged the suppliers to meet our objectives for packaging equipment that operates in-line with our existing SDC processing equipment and on-demand,” remarks Ocean Spray project engineering manager Joe Benevides. “The major equipment suppliers worked hand-in-hand with our engineering, R&D and operations departments to develop the line layouts and equipment capabilities.”

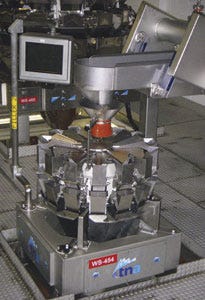

Ocean Spray knew from its work creating previous SDC packaging lines that the volume and stickiness of the product would require special attention. “Because the product is sticky, it builds up on the equipment, especially the scales and packaging equipment,” Ocean Spray project engineer Jeff Pratt states. “tna (www.tnasolutions.com) provided some innovative designs that improved our speed and precision for the 100-calorie form/fill/seal operation.”

According to tna North America marketing coordinator Maria Mejia, the SDCs' tendency to stick to most surfaces can make vertical transfer very slow or unpredictable. To overcome these problems, tna adapted its robag 3 rotary triple-jaw bagger, which uses a dimple finish on conveying surfaces that raises the product above the main conveyor surface to reduce the products' inherent sticking force. Wire mesh screens also were added to the bucket doors of the integrated Yamato (www.yamatocorp.com) radial-feed scale on the vf/f/s machine. The wire-mesh screens help reduce contact area on critical transfer areas. These adaptions ensure accuracy so that no more than 100 calories worth of the SDCs goes into each individual pouch; the customizations also enable the vf/f/s machine to run at its top speed, which is of high importance to Ocean Spray because the line operates in excess of 2,000 lb/hr. Ocean Spray's total annual processing capacity is 90 million lb of SDCs.

|

Safety first

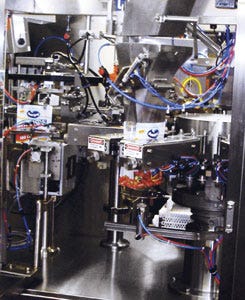

Concerned with more than just SDC consumer waistlines, Ocean Spray engineers also wanted to make sure that there was metal detection before the fruit was dropped into the metallized pouches. “Ocean Spray always considers product safety a top priority,” says Benevides. Fortunately, the integration of a Zero Metal Free Zone (ZMFZ) product-inspection system from Mettler-Toledo Safeline (http://us.mt.com/safelineus) is a standard offering with tna systems.

Designed for installation in small spaces, the inspection system can be installed in between a scale and a v/f/f/s machine to inspect food items in-flight as they enter the bag. The metal detector's internal cancellation field (ICF) technology uses a patented technique that enables high sensitivity settings, which allows close proximity to stainless steel machinery. ICF technology works by generating two magnetic fields; the secondary magnetic field is created internally and is opposed to the primary magnetic field produced by the detector.

|

The primary packaging material is coded with a best-by date using a thermal-transfer overprinter. |

To further ensure the safety of its product, Ocean Spray codes both the individual portion-packs and the secondary packaging with a best-by date. A DataFlex Plus thermal-transfer overprinter from Videojet Technologies, Inc. (www.videojet.com) codes the primary packaging material before filling.

The printer has an 8.4-in. SVGA graphical user interface and color touchscreen with icon-based controls that are designed to be easy to learn. The WYSIWYG job display has a zoom feature to reduce operator error and minimize the potential for printing incorrect codes. Three levels of password protection provide added security.

Because Ocean Spray's SDC line requires a high throughput, it is important that the printer has high production-line efficiency and low downtime. The printer's patented direct-drive ribbon technology contains few wearable parts, which increases reliability and minimizes downtime and costs associated with ribbon breaks. “Additionally, the unit features the simplest ribbon cassette on the market, making changeovers fast, easy and virtually fail safe,” says Videojet Technologies, Inc., North America thermal-transfer overprinter/secondary packaging product manager Phil Pasit. “The 1,000-meter ribbon also is the longest standard length on the market today, so there are less frequent changes and higher production-line efficiency.”

Each portion-pack is coded before the pouch is formed and filled. Ocean Spray codes the metalized barrier-lamination rollstock at the speed equivalent of 140 packs/min.

Twice measured

The volume of fruit in each filled portion-pack is checked again by an Ishida DACS-WN-003-SB/PB-1 checkweigher with air-blast rejector supplied by Heat and Control, Inc. (www.heatandcontrol.com).

|

To accommodate the sticky product and ensure accurate weighing, the integrated scale's bucket doors were fitted with wire-mesh screens. |

The anti-floor vibration device equipped with the system is designed to cancel out influences from external vibrations to provide more stable, reliable weighing. Other checkweigher features that help ensure that only precisely filled SDC packs reach consumers include a digital filter, digital signal processor and dynamic calibration. Automatic error-detection functions include power-down, photoeye, CPU, conveyor-speed, rejector stop position and zero-error checks.

The DACS-WN-003-SB/PB-1 uses double-beam loadcell weigh sensors that operate at speeds up to 330 times/min. To ease on-site adjustment for installation, the DACS-WN series has a modular design. “The versatility of the Ishida design allows the pre-configured system to handle Ocean Spray's application without any customization,” Heat and Control sales manager Brian Barr remarks.

To the top

Conveyors supplied by Key Technology, Inc. (www.key.net) carry the pouches to a PSG LEE fill/seal machine Model RG-150 from PPi Technologies Global [PPiTG (www.ppitechnologies.com)]. The fill/seal machine places six portion-packs into a premade standup pouch, which like the primary packaging, has been coded with a best-by date using a Videojet DataFlex Plus printer.

While the RG-150 is specifically manufactured for handling open-top, premade, side-gusseted pouches, PPiTG worked very closely with the Ocean Spray team to create a machine that would not require the pouches to be sealed short of the top.

|

Ocean Spray measures each 100-calorie Craisins® pack twice. A scale is used to weigh the fruit before filling; then, the filled packs are run past a checkweigher, above, to ensure only precisely filled packs reach consumers. After being coded with a best-by date, the primary packaging pouch material is fed into a vf/f/s machine, below. |

|

“This RG-150 model will run the standard open-top, side-gusseted pouch where the gusset extends all the way to the top and creates a wide mouth for filling,” PPiTG CEO R. Charles Murray explains. “The wide mouth of the side-gusseted pouch allows the smaller pouches to be filled at the speeds required without sticking in the funnel.” The fill-seal machine can fill up to 35 standup pouches/min.

Adaptions made by the joint engineering teams include a specialized transition chute made with a proprietary PPiTG design, and a focused pouch vibration and top-down product-plunge assist, which the supplier says helps assure consistent filling at high speeds.

Space savvy

The multipacks are put into a shipping container using a All-In-One pick-and-place case and tray forming, packing and sealing system that was originally supplied by Goodman Packaging Equipment (www.goodmanpkg.com). The equipment manufacturer has since been acquired by Pearson Packaging Systems (www.pearsonpkg.com) in an agreement signed in December 2008.

Designed to provide a corrugated reduction and flexibility in case design and efficient packing within a single frame, the All-in-One top-load packing design allows the machine to pick and place both flexible and rigid containers in a variety of pack patterns before sealing the top of the shipping container with hot-melt adhesive.

“The key feature for this machine is its capability to pack a top-load wraparound-style case in a small footprint machine,” Goodman Packaging president Billy Goodman explains. “Top-load packing allows for any type of package, flexible or rigid, to be packed into the case in a variety of pack patterns. The wraparound case style provides 'sustainability' by, in most instances, reducing the amount of material used while providing greater flexibility in the style of case presented.” Pearson Packaging now distributes the All-in-One.

|

The secondary packaging for the multi-pack is a pre-made, side-gusset pouch. Above, a fill-seal machine deposits six, filled, 100-calorie packs into each standup pouch. Below, filled standup pouches travel down a conveyor to the casepacker. |

|

Before the cases are hand-palletized for shipment, they are coded using an Imaje 4040 ink-jet printer from Markem-Imaje (www.markem-imaje.com.) The coder's piezo-electric printhead images at a vertical resolution of 180 dpi at speeds up to 150 feet/min. It has a WYSIWYG display on a 10.4-in. VGA screen.

Keeping it lean

To optimize the packaging line's operation, Ocean Spray brought in systems integrator Superior Controls, Inc. (www.superiorcontrols.com), which installed a manufacturing execution system (MES) that will allow Ocean Spray's team to continually monitor and improve the packaging line's operation.

The MES system installed its Proficy Plant Applications from GE Fanuc Automation, Inc. (www.gefanuc.com). Superior Controls project manager Sean Hoffman led the systems integrator's efforts for the project, which took the off-the-shelf MES product and optimized it for the Craisins® 100-calorie pack line.

The customized software monitors and reports overall equipment effectiveness (OEE). As a key performance indicator in lean-manufacturing efforts, OEE offers a quantifiable way to report overall utilization of facilities, time and material. Critical information collected by the MES includes reporting downtime and runtime as well as the reasons for downtime.

Designed to digitize and collect information generated throughout a production facility, Proficy Plant Applications creates what GE Fanuc describes as a “virtual plant.” A packaging-line manager or operator can access the information on-demand, then use the data to measure performance in real time.

“The software will help as Ocean Spray ramps the line up, and they can see exactly where the problems occur,” Superior Controls president Rick Pierro explains.

|

The case packer boasts a top-load design that enables Ocean Spray to pack the flexible, standup pouches without the floorspace demands of a large machine. |

The information collected by Ocean Spray can be used to continually improve the Craisins®100-calorie pack line, and, potentially, enable Ocean Spray to create better SDC packaging lines in the future.

Coast-to-coast growth

SDCs are poised to continue to be a large part of the Ocean Spray offering. The company plans to add 15 million lb of SDC processing capacity this year.

As of presstime, Ocean Spray completed production for another SDC operation at a facility in Wisconsin Rapids, WI; operates an SDC packaging facility in Tomah, WI; and has commissioned a plant in Markham, WA.

More information is available: |

Pearson Packaging Systems, 800/732-7766. www.pearsonpkg.com. |

Markem-Imaje, 866/263-4644. www.markem-imaje.com. |

GE Fanuc Automation, Inc., 800-433-2682. www.gefanuc.com. |

Heat and Control, Inc., 510/259-0500. www.heatandcontrol.com. |

Key Technology, Inc., 509/529-2161. www.key.net. |

PPi Technologies Global, 941/359-6678. www.ppitechnologies.com. |

Mettler-Toledo Safeline, 800/836-0836. http://us.mt.com/safelineus. |

Superior Controls, Inc., 800/639-1736. www.superiorcontrols.com. |

tna, 972/462 6500. www.tnasolutions.com. |

Videojet Technologies, Inc., 800/843-3610. www.videojet.com. |

Yamato Corp., 262/236-0000. www.yamatocorp.com. |

About the Author(s)

You May Also Like