A food packaging scientist finds much to like in Australia from legacy heavyweight containers that optimize recycling to an adventurous variety of packaging and an impressive cold chain.

March 13, 2023

G’day! I’ve been lucky enough to work, travel, and explore food packaging in Australia for the past five weeks. My adventure revealed five takeaways on the current state of Australian food packaging.

1. Legacy heavyweights.

The thick side walls, shoulders, and bases of MasterFoods blowmolded high-density polyethylene condiment squeeze bottles (below left) are reminiscent of the 1990s, i.e., before lightweighting. Because the heavier-weight squeeze-bottle’s packaging contains more polymer per container, recycling is more economically viable in terms of the amount of polymer collected per container.

Hamper's Corned Beef tin (below right) is also packaged in a small, 3-piece tapered steel can. It offers an attached key to first open and then roll up the steel sidewall to access the product.

Both legacy packages offer the required shelf life in extreme heat, as well as the ability to traverse 3,000 to 5,000 miles of road-based distribution circuit. Traveling across this expanse is necessary because goods are frequently imported from a single port or manufactured at a single site in a country the size of the continental US.

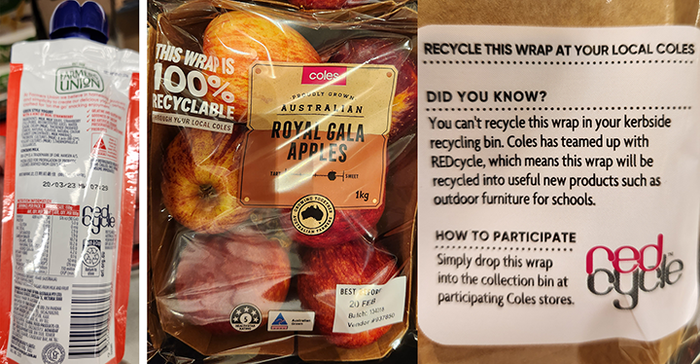

2. Store Drop-Off Implementation for flexible packaging (image below).

Store Drop Off (SDO) has been implemented throughout Australia, with consumers returning over 10,000 tonnes/11,023 tons of flexible packaging to more 2,000 stores. While major grocers Coles and Woolworths private label and major brands display the SDO logo and enthusiastic instructions on how and why to drop off all flexible packaging at stores, smaller brands do not.

Regardless, all plastic-containing flexible packaging, including metalized standup pouches, laminated confection overwraps, and vacuum lidding from meat trays, can be returned to the store. Mixed flexible packaging recycling is technically possible, and facilities are available.

Unfortunately, the value chain and economics to drive the actual recycling were a bit of a "dog's breakfast," as the Aussies say. More unfortunately, the REDcycles pandemic has resulted in reliance on a single recycler. Even more unfortunately, that single recycler’s factory was destroyed by fire, resulting in stockpiling of collected film and a pause in the program.

Even if the recyclable plastic is incinerated, BTUs are produced and used as energy, preferable to landfilling flexible packaging.

In the long run, I trust that Australians will not allow the industry to revert to pre-SDO levels and will move forward with environmental incentives and more drop-off locations to convert flexible packaging into durable goods such as construction materials, asphalt additives, and furniture.

3. Island nation driven by exports and imports including offshore processing.

Australia exports many raw ingredients and imports many packaged foods. For example, Queensland, Australia, is the world's seventh largest exporter of sugar cane; the cane is processed offshore before being imported as granulated, powdered, or cubed sugar and as an ingredient in various products. This means that while Australian ingredients are used in foods, many processing and packaging operations are performed offshore. This provides access to a wide range of packaging materials. However, it requires a trusted value chain and packaging analysis to ensure that packaging is compliant and not fraudulent.

|

4. A multicultural society leads to innovation and variety in packaging.

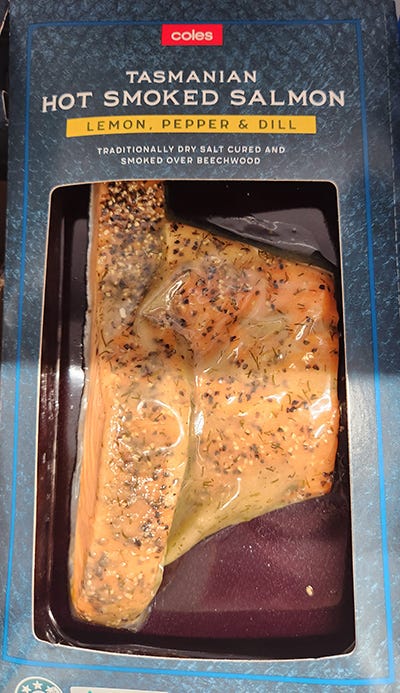

Australia has a robust adventure culture, which is also present in packaging, such as the paperboard sleeved vacuum packed thermoform of flavored salmon seen at the left.

Packaging for healthy, convenient products is refined, portioned, and simple to understand. There is also an astonishing range of packaging textures, sizes, shapes, and designs. Perhaps this is inspired by a multicultural society in which nearly 50% of people have a parent born outside of Australia and nearly 30% of the population was born outside of Australia.

This cultural mix introduces new ingredients, new processes of meal preparation, and a fusion of tastes, all of which necessitate packaging.

5. Big country, tight cold chain.

The cold chain distribution system, which necessitates long-distance transport within Australia, is impressive.

For example, despite the remote location and over 100F heat in February, the 1,600 square mile Curtin Springs Cattle station, a friendly place to wait out a truck repair, offered refrigerated and frozen products. This is an example of a secure, yet remote cold chain.

However, intelligent packaging can be used to detect temperature abuse; this would ensure food safety and be associated with products such as high-pressure processed almond milk and refrigerated meat. There's a need to focus on preventing food waste using more active and intelligent packaging.

Claire Sand has 30+ years of experience in industry and academia. She’s owner of Packaging Technology and Research and Gazelle Mobile Packaging and an Adjunct Professor, CalPoly, Michigan State University, and the University of Minnesota. You can reach her at www.packagingtechnologyandresearch.com or [email protected].

About the Author(s)

You May Also Like