The global fruit and vegetable company replaces bags with bands and clamshells with paper cups, employs reusable packaging, and reduces food waste.

September 8, 2021

Fresh Del Monte, Coral Gables, FL, one of the world’s leading vertically integrated producers, distributors, and marketers of fresh and fresh-cut fruits and vegetables, is far more than a provider of bananas and pineapples.

“We sell avocados, grapes, tomatoes, melons, and citrus, among other fruits and vegetables,” explains Hans Sauter, Chief Sustainability Officer and SVP of Research & Development. “Our products include prepared fruit and vegetables, juices, beverages, snacks, and desserts, and are sold in more than 90 countries around the world.”

The company released the 2020 Sustainability Report several weeks ago. “We’re very proud of the steps we’ve taken, and are taking to create a more sustainable, equitable, and resilient food system,” says Sauter, who responds to Packaging Digest’s questions about Fresh Del Monte’s efforts in sustainable packaging in this exclusive Q&A.

Tell us about the company’s overall packaging mix.

Sauter: The overwhelming majority of our packaging is secondary packaging, which is essential for safely transporting our products to the markets and delivering the freshest and best quality possible to our consumers. Paper packaging represents more than 70% of the materials we use, while wood for pallets is more than 15%.

100% of the containerboard we source to manufacture our corrugated boxes comes from forests certified as responsibly managed. Furthermore, we have set an aggressive goal to double the amount of recycled content in our paper packaging by 2026.

How does the company view sustainable packaging?

Sauter: As a company that relies on Earth’s natural resources, we appreciate the importance of managing our use of limited resources in our packaging materials and minimizing our waste footprint. Our goal is to eliminate unnecessary packaging materials, increase recycled content, and develop reusable and recyclable packaging.

|

We take a value chain approach to understand opportunities to reduce waste while considering how regulations, the maturity of the recycling industry and other factors can support our goals. Our mission is to design and source packaging materials responsibly, minimizing the impact to the environment while ensuring the optimal protection of our products, so that there is neither food waste due to insufficient packaging, nor unnecessary landfill waste due to overpackaging. We are also working toward implementing circular economy principles, by setting up dedicated facilities to recycle plastic and repurposing it into new packaging materials.

We've focused heavily on reducing unnecessary packaging in as many areas of our business as possible. Some examples include initiatives to reduce plastic and paper from our banana packaging, lightweight initiatives to our fresh-cut packaging in the UK, as well as packaging reductions on our grape program out of Chile. We are currently in the process of recruiting a packaging sustainability and innovation manager who will form part of our packaging department, and whose responsibility will be to help us lead the company towards achieving the aggressive goal we have defined for the years to come. Such targets include an important increase in recycled content in our most highly consumed secondary packaging, reduce the amount of virgin plastic used on our consumer packaging, and significantly increase the use of reusable plastic containers (RPCs), among others.

Can you “cherry pick” other examples of sustainably improved packaging?

Sauter: As we expand our fresh-cut business in Europe, we introduced the first paper-based cup for fresh-cut fruit in Italy. This exciting package is made with FSC-certified paper and represents a reduction in plastic anywhere from 78.5% to 90.3% versus the traditional plastic clamshell.

In bananas, our product, we’ve converted multiple packs away from consumer plastic bags and into bands. Initiatives like this have led to consumers taking home 85-90% less plastic, which is significant when talking about the large volumes that bananas represent.

How does the brand message sustainable changes on-package?

Sauter: To inspire healthy and balanced lifestyles and educate consumers about the journey of their food, we share wholesome and delicious recipes featuring fresh produce and easy, fun ideas to incorporate more fresh food into everyday diets, information about our sustainability efforts, farms, environmentally friendly practices, and the journey of food items throughout the supply chain. We also use product labels to provide information to consumers about sustainability certifications and programs, and recently launched our Bunch of Good campaign with a communication program highlighting our commitment to communities, education, ecosystems, healthcare, and wildlife preservation.

How is the company working to reduce food waste?

Sauter: We take a comprehensive approach to reducing food waste at all stages—from the farm to the marketplace. Thanks to the creativity and dedicated efforts of our team members, 90% of our global food waste including unsold product was diverted from landfill in 2020, with a quarter of that going to feed hungry people. Some food waste, such as scraps from skins or pineapple crowns, or produce that is no longer optimally fresh, cannot be donated to people. In these cases, we will try first to divert the waste to provide animal feed, and secondly to other alternative uses such as biofuel and compost.

Our approach not only reduces the environmental impacts of food waste going to landfill and releasing toxins and greenhouse gases, but also helps communities access healthy fruits and vegetables. We use the EPA Food Recovery Hierarchy to prioritize our actions for addressing food waste, with the preferred option being to reduce the amount of waste generated, followed by finding alternative, value-added uses for produce that can still go toward feeding people. For example, produce that does not meet the cosmetic requirements (e.g., incorrect size pineapple for retail specifications) of customers can still be converted into frozen chunks, pulp, or juices.

Packaging plays an important role in protecting and containing food as it moves through the supply chain. Packaging can either extend or shorten the shelf life of food products. Packaging designed adequately to meet the food products needs to extend shelf life by reducing water loss (wilting), product respiration (food aging), oxidative browning (food appearance), and by prevention of spoilage (growth of spoilage organisms) and ethylene production (fruit ripening). However, in inadequately designed food packaging, the food will go to waste easily. Fresh Del Monte has a team of experts in packaging, food and post-harvest technology, and microbiology to design packaging suitable for the wide range of food products with the goal to extend shelf life. Studies suggest in life cycle analyses, environmental impact (including GHG emissions) caused by food waste can be higher than those caused by packaging.

In addition to five food-waste reducing case studies found on pages 46-47 of our 2020 Sustainability Report, I can reference two others:

Fresh-cut vegetable process Mann Packing has developed a unique program to utilize by-products from the production of ready-to-eat broccoli and cauliflower florets (crown, stems, stalk, tender crown leaves) in a variety of value-added products such as broccoli slaw, cauliflower rice, “broccoli clover”, veggie side dishes, and veggie bits.

Fresh Leaf Farms, which processes and packages blends of lettuces and leafy greens, is diverting green waste as animal feed to local dairies.

We are continuously exploring new technologies and potential applications to “upcycle” by-products from our fruit and vegetable processing operations to further reduce food waste.

Please comment on your use of reusable plastic containers (RPCs).

Sauter: We’ve worked over the years to increase the use of RPCs across different commodities—in 2020 we used more than 14 million RPCs. Most RPC programs have been done in an effort to replace one-way corrugated boxes. Some programs have been implemented in collaboration with strategic customers, while others have been internal initiatives such as the use of RPCs for crownless pineapples destined to our fresh cut facilities in North America, Japan, and Korea.

Does the company use any other types of reusable packaging?

Sauter: We’ve implemented a CHEP pallet program in which we use CHEP pallets for bananas, melons, pineapples, and some other commodities coming to North America. In 2020, more than 85% pallets we used to ship our core products to North America are CHEP pallets. These make their way into the pool system and are reused many times after delivering our products to our customers.

These pallets all use timber from certified sustainable sources and are part of the CHEP Pool pallet program in which the pallets are re-used multiple times after bringing our products into the country. In 2020, for the North American market alone, 85% of the pallets used for our core products were CHEP pool pallets, saving more than 1.1 million pounds of solid waste and avoiding more than 386 metric tons off CO2 equivalent.

What’s the brand’s view of flexible packaging including bags and pouches, which are a highly efficient format, though not generally recycled?

Sauter: Flexible packaging used in the fresh produce industry serves an important purpose by ensuring the safety, maintaining the freshness, and extending the shelf life of fresh produce from the manufacturing facility through the entire supply chain. Packaging plays an important role in reducing food waste and its negative impact on the environment. When food ends up in landfills and decomposes it creates methane, a harmful greenhouse gas that accelerates climate change. Today’s consumers of fresh produce are looking for products that are convenient, fresh, and environmentally friendly. Therefore, our industry is working to develop more sustainable packaging solutions. The flexible films industry is advancing fast by investing in film technologies that are recyclable, have recycled content, or are compostable.

Recently, monomaterial packaging films have been developed, which allow for in-store recycling. But, in contrast to previous recyclable films, monomaterial packaging films have a high clarity and stiffness and provide a wide range of permeability properties needed to maintain product freshness and shelf life equivalent to non-recyclable poly-material blends used in flexible packaging now.

While the use of post-consumer recycled (PCR) material in flexible films for food is yet to become widely used, we are keeping an eye on developments in this area, too. Our company is working to reduce packaging where reasonably possible and validate the feasibility of in-store recyclable monomaterial packaging films for our fruit and vegetable products.

Please share your final thoughts.

Sauter: Eating healthily should not be difficult. We want to show our on-the-go consumers that fresh snacks and wholesome meals can be convenient and within reach. Freshly cut and ready-to-eat fruits are an excellent way to make eating healthy convenient, however, it also results in additional plastic utilization.

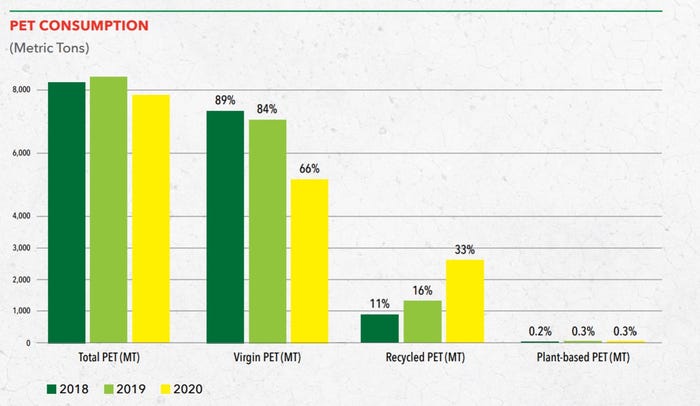

In our European operations, we have achieved 100% PCR content in our fresh-cut produce containers and we continue to expand these learnings to our other regions. Worldwide, in 2020, we doubled the amount of PCR in our fresh-cut container from 16% percent in 2019 to 33% in 2020 (see chart above).

Additionally, this year we’ve set new ambitious goals to take our packaging sustainability program to the next level. You can read about those in our 2025 and 2030 Sustainability Goals.

You May Also Like