July 27, 2016

Before deciding which processing method to use for your food products, consider the packaging limitations, challenges, opportunities and costs.

Consumers increasingly demand a safe food supply without sacrificing nutritional content, quality or shelf life of foods they buy. Luckily, many food processing methods are adjusting their operations accordingly. But how do these processing improvements change the product’s packaging requirements?

Firstly, the selection of the processing technology depends on the food. Critical properties are pH, moisture content, phase (solid, semi-solid, liquid with particulates, liquid) and heat stability. Next, the targeted agent to eliminate (such as microorganism, spore or undesirable enzyme) is specified. Their acceptable risk levels in foods depend on safety regulations. The intended shelf-life is important, as well as the environment in which food will be stored (such as room temperature for two years, or refrigeration with an expected shelf life of one month). Then, the preservation of nutrients and quality, and economic viability are considered.

Selection of packaging is an integral part of this process.

We present packaging implications for the following thermal and non-thermal processing methods:

• Retort processing;

• Aseptic processing;

• Microwave-assisted thermal sterilization (MATS);

• High- and ultra-high-pressure processing (HPP / UHP); and

• High-intensity light pulse (HILP).

THERMAL METHODS

In thermal processing, the objective is to increase the temperature of the food to reduce the target agent (typically microorganisms or their spores) to an acceptable level. However, nutrients and quality factors are also reduced by heat, at different rates. Blanching, pasteurization and sterilization can be selected depending on the intended severity of heating. The faster the cold point of food reaches the desired process temperature and the faster it is cooled to ambient temperature, the shorter the overall process, with better nutrient and quality retention.

Retorting

Retorting can be applied for pasteurization (elimination of vegetative pathogenic microorganisms) requiring refrigeration and limited shelf life (such as two months) or sterilization (reduction of heat-resistant spores to acceptable levels, resulting in long shelf-life, such as two years at room temperature).

This method can be applied to solids, semi-solids, liquids with particulates or liquids.

The cost of thermal processing is generally lower than non-thermal methods.

Packaging implications: The packaging material must resist temperature and mild pressure without changing barrier properties and without interacting with the food. Metal or plastic cans, glass containers, plastic or metallized pouches, and trays are recommended.

Since the food is packaged prior to processing, the chance of re-contamination is much reduced. Thermal processing has been used for more than a century, therefore the technology, know-how and experience exist. Precise methods to calculate safety and reduction in nutrients and quality attributes are known. Optimization of the process for time and temperature, for the heating medium and mechanical agitation are available.

Depending on the food, though, nutrients and quality attributes can be significantly reduced.

Although a mature technology, retort processing continues to see improvements, such as these Allpax Orbital systems that help save floorspace with doors that swing up rather than out.

Aseptic processing/packaging

Aseptic processing is limited to foods that can be pumped through heat exchangers, and can be used for pasteurization or sterilization (see descriptions above in the Retorting section). This is also a mature technology, similar to retorting.

Since heating and cooling of the product can be accomplished faster, better quality products are obtained.

Packaging implications: After processing, the product needs to be placed in appropriate containers and sealed, in a sterile environment. The packaging material must be formed, and sterilized, within this environment (using chemicals and/or light sources) before filling. Rectangular cartons, commonly used in aseptic packaging, allow significant improvements in space savings in warehouses and in shipping, compared to rigid containers such as bottles, because they are formed from rollstock, which requires a fraction of storage space versus formed packs.

With today's short runs, aseptic packaging systems need to be flexible in the package styles they can handle. This Tetra Pak A3/Flex machine, for example, uses servo motors on the jaws to speed changeover between different packages.

Microwave-assisted thermal sterilization (MATS)

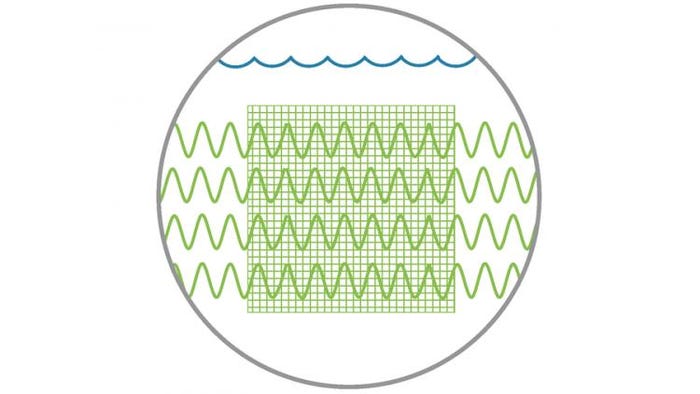

Microwave-assisted thermal sterilization (MATS) allows in-container processing of foods with rapid heating, and therefore better nutrient and quality preservation compared with traditional retorting. Water is used as the heating medium, in combination with the direct exposure of the packaged food to microwaves. The presence of water eliminates the non-uniform heating and edge overheating effects of the traditional microwave heating. The frequency used is 915 MHz instead of the 2450 MHz used in home microwave ovens. This allows better penetration and more uniform heating.

Solids, semi-solids, particulates in liquids and liquid foods can be processed. Typically, high-barrier plastic pouches, trays and lidding are used as packaging materials (such as ethylene vinyl alcohol or EVOH).

Packaging implications: Since microwaves are used, the packaging material should be transparent to the frequency used. The requirements of minimal or no food-package interactions also apply in this method.

MATS can reduce processing times from one-quarter to one-tenth of the time required for conventional sterilization. However, for non-homogeneous foods, the prediction of the cold point and the development of the thermal process schedule are challenging.

Microwave-assisted thermal sterilization (MATS) heats the outside of packaged food with hot water while also zapping the food internally with microwaves at a frequency of 915 megahertz. In this process, the food is sterilized quickly and yet rapidly cools down to reduce heat damage. Illustration is courtesy of 915 Labs.

NEWER, NON-THERMAL METHODS

Since heating may reduce the nutrient content and the quality of the food, several new methods have been developed to non-thermally process foods. This means that microorganisms and undesired enzymes can be inactivated without heating the food. Ultra-high pressure (UHP), pulsed electric fields (PEF), pulsed magnetic fields, dense phase carbon dioxide (DPCD), high intensity light pulses (HILP) and other technologies have been developed.

We’ll take a closer look at two of these: UHP and HILP.

High- and ultra-high-pressure processing (HPP / UHP)

In ultra-high pressure (UHP), typically, foods are packaged, then placed in a high-pressure vessel (imagine the barrel of a cannon). The container is filled with a working fluid (typically water), and pressurized to the process pressure (usually 200 to 1,000 MegaPascal/MPa or about 28,993 to 145,023 pounds per square inch/psi). As a comparison, the pressure at the deepest point in the ocean is 109 MPa. After about five minutes, the pressure is reduced, and the packages are removed from the high-pressure vessel.

Solids without porosity, semi-solids, liquids with particles and liquids can be processed with UHP. If there are air pockets or pores in the food, pressure will eliminate these pores, and the food will shrink/deform.

High pressure inactivates mostly the vegetative cell of microorganisms. To inactivate microbial spores, temperatures around a minimum of 185-deg F. are required. Although this is heating, when compared to the nearly 220-deg F. temperature required in traditional thermal processing, the loss of nutrients and quality attributes is much less.

Some of the undesirable enzymes are not reduced by UHP; indeed, some enzymes increase in activity. Residual enzymes are harmful to the quality and shelf-life of foods treated by UHP.

During compression the temperature increases by about 5.4-deg F. for every 100 MPa. Therefore, excessive heating must be avoided by controlling pressurization rate. For example, if the product starts at room temperature (68-deg F.), increasing the pressure to 700 MPa will also increase the temperature by about 70-deg F., resulting a product temperature of 106-deg F. Upon depressurization, the temperature is reduced by 70-deg F. This instantaneous increase/decrease of temperature by pressure can be used in a combination of heating and UHP method called pressure-assisted thermal sterilization (PATS). The time-to-sterilization of the process, as well as cooling time, can be much reduced by PATS, resulting in less loss of nutrients and quality attributes.

Packaging implications: Since high-moisture foods compress significantly (10% to 20%) under pressure, the packaging material and design must accommodate this temporary shrinkage during processing. Therefore, hard-sided packages (such as metal cans or glass bottles) are not appropriate. Flexible packages, such as plastic pouches or bottles that flex up to 15% on any one surface, can be used.

However, UHP may disrupt flexible laminations: Blistering of foil laminations has been observed. Barrier properties of packaging materials may be altered. The capacity for absorbing flavor compounds from food (scalping) may decrease. Significant increases in the permeability of oxygen, carbon dioxide and water vapor were observed in metallized polyester (PET) films after a high-pressure treatment.

UHP is a commercial technology, with an increasing accumulation of data and know-how about its applications. Since the effects of isostatic pressure instantaneously apply at all point of the food without regard to size or shape, this allows for much flexibility in the choice of containers. Multi-faceted containers (hexagons) increase packing into cylindrical pressure vessels, and improve the economics of the operation.

Two points need to be considered for the application of UHP. First, the initial equipment costs of UHP are high due to pressure. For example, to pressurize 450 liters of high-pressure vessel to 600 MPa requires a significant wall thickness. Also, muscle proteins tend to denature by UHP, resulting in increased toughness and change in the color of muscle tissue.

Production time is also a consideration. If the food is pre-packaged (which it usually is), then the UHP will be applied batch-wise. For liquids, semi-batch operations are possible: While one high-pressure vessel is being filled, another is being pressurized—and yet another is being emptied.

High-pressure processing (HPP) systems, such as this HPP 55 system from Multivac, protect food quality by using pressure rather than heat to kill microorganisms.

High-intensity light pulse (HILP)

High-intensity light pulse (HILP) is an emerging non-thermal technology for microbial inactivation on the surfaces of foods and packaging materials. Intense, very short duration pulses of white light (200 to 1,100 nanometer/nm) can inactivate both vegetative cells and spores. The intensity of the light (measured as joules/cm2), as well as the ultraviolet (UV) component (UV-C, 200 to 280 nm) of the light spectrum, contribute to the lethal effect.

The susceptibility of microorganisms to HILP in decreasing order is: Gram-negative bacteria, Gram-positive bacteria and fungal spores. UV absorption by DNA and its disruption is the primary cause of inactivation.

There are reports of enzyme inactivation by HILP in clear liquids, but the restriction to surface treatment in solids renders this method ineffective for enzyme inactivation in most foods.

Packaging implications: If surfaces of the in-package food are to be treated, the packaging material must be transparent to UV light.

HILP is superior to chemical sterilization of package surfaces, such as by hydrogen peroxide or peracetic acid, because it does not leave any undesirable chemical residue. Pulsing of the light (instead of continuous light) reduces heating of the sample. Wavelengths that produce undesirable attributes can be eliminated by filtering. There are specific advantages in certain foods. For example, UV treatment of grapes increases resveratrol, a desirable component, by 10-folds.

HILP is effective only at surfaces, and in clear liquids. Data on kinetics of inactivation of different microorganisms at different conditions is being accumulated. The effect on nutritional components or the formation of undesirable chemicals has not been studied (UV is known to promote the oxidation of unsaturated lipids). “Shadowing” is the lack of uniform treatment due to surface irregularities of the food. Methods need to be applied to treat all surfaces of the food. Short UV light can generate ozone, which has regulations and limits regarding worker exposure.

A dry sterilization method, high-intensity pulsed light (HILP) sanitizes packages without water or chemicals and is billed by provider Claranor as a "sustainable" process.

Having a better understanding of what happens to your packaging during processing enables you to make better material choices to make sure you deliver the best tasting, healthiest and safest food to today’s discerning consumers.

Murat Balaban is professor and retired chair of Food Process Engineering at the University of Auckland in New Zealand. His research and teaching experience in the food processing area covers more than 40 years.

References:

Barbosa-Canovas G V, Medina-Meza I, Candogan K, Bermudez-Aguire D. 2014. Advanced retorting, microwave assisted thermal sterilization (MATS) and pressure assisted thermal sterilization (PATS) to process meat products. Meat Science. (98): 420-434.

Bhunia K, Sablani S S, Tang J, Rasco B. 2013. Migration of chemical compounds from packaging polymers during microwave, conventional heat treatment, and storage. Comprehensive reviews in food science and food safety. (12): 523-545. doi:10.1111/1541-4337.12028

Bull M K, Steele R J, Kelly M, Olivier S A, Chapman B. 2010. Packaging under pressure: effects of high pressure, high temperature processing on the barrier properties of commonly available packaging materials. Innovative Food Science and Emerging Technologies. (11):533-537. doi:10.1016/j.ifset.2010.05.002

Han J H. 2007. Packaging for non-thermal processing of food. Blackwell Publishing. Ames, Iowa, USA. ISBN-13: 978-0-8138-1944-0/2007.

Morris C, Brody A L, Wicker L. 2007. Non-thermal food processing/preservation technologies: a review with packaging implications. Packaging technology and science. (20): 275-286. DOI: 10.1002/pts.789

Additional resources, by processing method:

Retort

“'Continuous retort' system could revolutionize chilled-food packaging” from Packaging Digest

“First U.S. Shaka production retort shipped” from Packaging Digest

“Test lab helps optimize products' retort processing” from Packaging Digest

Aseptic

“Pixie Dust to ‘magically’ sterilize stand-up pouches and bag-in-box” from BeverageDaily.com

“Aseptic packaging stirs up the beverage business” from Packaging Digest

High- and ultra-high pressure (HPP/UHP)

“Performance under pressure” from Packaging Digest

“Additional HPP resources” from Packaging Digest

“Surprising developments in HPP packaged food” from Packaging Digest

“Unique chilled soups are bottled and high-pressure processed” from Packaging Digest

“4 Euro-style functional food packaging innovations” from Packaging Digest

Microwave-assisted thermal sterilization (MATS)

“Latest packaging technologies help improve combat rations” from Packaging Digest

“Food packaging identified for new MATS processing” from Packaging Digest

High-intensity pulsed light (HILP)

“Shedding Light on Food Safety: Applications of Pulsed Light Processing” from Food Safety magazine

“High intensity pulsed light technology in food processing” from Intl. Journal of Science, Environment and Technology

“High-intensity pulsed light cuts Campylobacter on poultry and packaging” from FoodQualityNews.com

“Cup sterilization with Pulsed Light 2015” video from Claranor

***************************************************************************************

Explore cutting-edge packaging, manufacturing and automation solutions from hundreds of exhibitors at MinnPack 2016 (Sept. 21-22; Minneapolis).

About the Author(s)

You May Also Like