Food Packaging

FB-Stream-GettyImages-ProStock-1305346806-1540x800.png

Food & Beverage

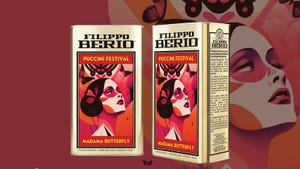

Best in New Food and Beverage PackagingBest in New Food and Beverage Packaging

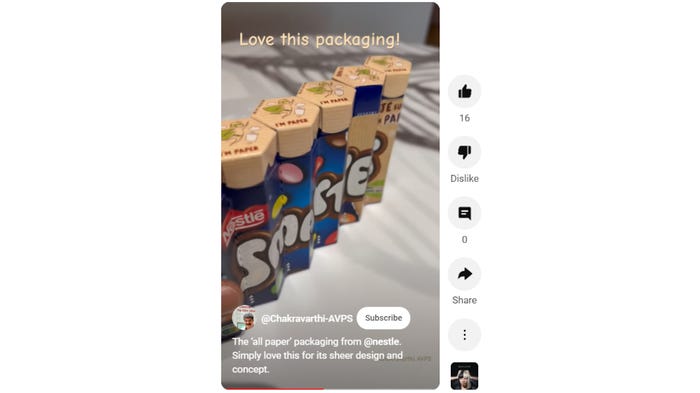

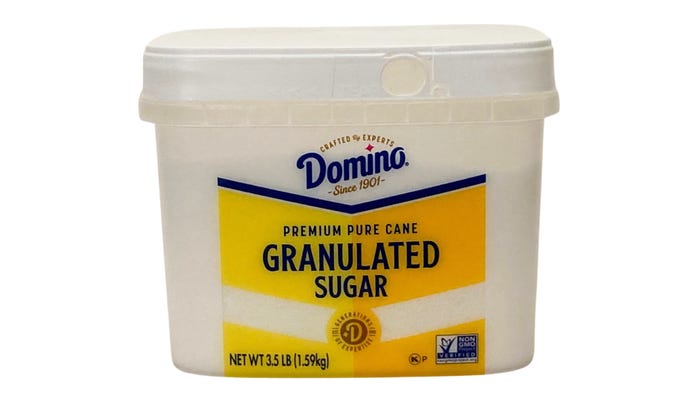

Woody food packaging, new spoilage sensor, rPET trays from PET trays, film is bananas, Coca-Cola's Marvel-ous cans, Postal tea, milk jug of vodka.

Sign up for the Packaging Digest News & Insights newsletter.

.png?width=300&auto=webp&quality=80&disable=upscale)