March 11, 2015

Research from the Food Marketing Institute shows a continuing trend of consumers cooking more meals at home. In its FMI Grocery Shopper Trends 2009 report, the group noted that 55 percent of shoppers surveyed prepared more meals at home during the last year. A primary driver for the interest in home cooking was budgetary pressures felt by shoppers in every income bracket due to the recession. When shopping for home-cooked meals, 40 percent of these consumers looked for easy-to-make recipes.

This trend was also evident when FMI conducted its Grocery Shopper Trends 2010 survey. Again, more than half of the shoppers surveyed were preparing more meals at home than they did one year ago.

"Shoppers have gained a renewed appreciation for saving money through home-cooked meals, comparison shopping, store selection, brand preference, coupons and more," says FMI president and CEO Leslie G. Sarasin. "They choose to save money by eating at home, but they also believe, overwhelmingly, that the food they eat at home is healthier than eating away from home. It is clear supermarkets are positioned to help their customers save money and help them make healthier choices when it comes to food."

This is the trend that McCormick Canada sought to capitalize on when it updated the packaging for its Club House Core Spices and Seasonings.

McCormick Canada product manager Linda Stiles explains, "In moving to a new design for the Club House Core Spices, we wanted a more contemporary, upscale look that also leveraged fresh and natural. The new look takes advantage of the current trend to cook or bake more at home and will inspire consumers to shop the spice aisle."

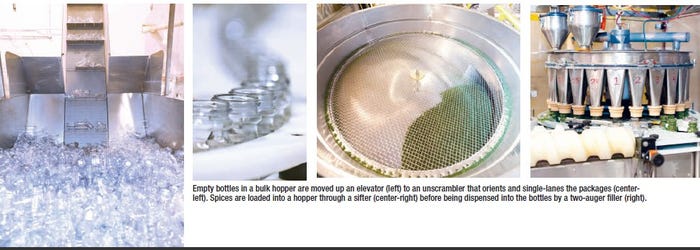

unscrambler through filler

These changes include beautiful photography on a clear polyolefin label showing the product in its natural, unprocessed state; easy to read, clean, modern fonts; and ideas on how to use the product highlighted on the side or back panel.In addition to the clear label that allows the texture and color of the spice or herb to be seen in the 250-mL bottle. An embossed cap was designed and produced for McCormick by Berry Plastics.

Two other packaging formats also were updated: a 1-L club pack size and a tin container. On the club pack size, there is a new bottle design that is ergonomic and easier to handle and a new red cap that maintains the dual flip-top opening feature. On the tins, the variety name was added to the side panel for ease-of-reading in the cupboard. The spice tins also received a new red flip-top lid that maintains the tamper evident tab.

Graphic design for all packaging was completed by Marovino Visual Strategy Inc., and prepress work for the club pack bottle was completed by Novellus Graphics. Prepress and label printing for the Club House 250-mL bottle was completed by All Stick Label, while label printing for the Club House 1-L bottle was completed by Wright Lithographing Co. Ltd.

Measuring design efficacy

In November 2009, McCormick Canada took the new Club House packaging design to consumer research company Ipsos, which used vision technology by Optiscan Pty Ltd. to measure respondents' eye movements when viewing a planogram.

"Results showed that consumers were very accepting of the packaging update, and were excited to see the evolution of the Club House brand," says Stiles. "Some descriptors used for the new look were ‘appealing, inspiring, educational, modern and unique to other offerings in the marketplace'-all very positive associations for the brand."

The new Club House Core Spice packaging design had strong results for purchase intent, overall likeability and a change in feelings toward Club House as a brand. For purchase intent, 41 percent of respondents said they would definitely buy the new packaging compared to 23 percent that would definitely buy the old packaging. Overall likeability went from 33 percent that liked the old design very much to 67 percent of respondents stating they liked the new design.

"Having such a strong likeability score for the new Club House design highlights the potential this new design will have to drive sales growth," states Stiles. "There was also a significant change in feelings towards Club House after seeing the new design look-the new design had 35 percent of respondents stating they had a much better opinion about Club House after seeing it versus just 7 percent stating they had a much better opinion of Club House after viewing the old packaging."

More than good looks

McCormick took a two-fold approach to the packaging update project, looking not only at improving the design of the spice packaging but also at how the spices are packaged. The commercial project for The Club House package redesign was combined with a capital project to improve packaging operations for the spices housed in the 250-mL square-pedestal bottles.

The packaging line's nominal filling speed was increased to 140 bottles/min, with actual speeds adjusted to meet demand that varies throughout the course of a year.

The updated line is located at the McCormick facility in London, Ontario, but the spice manufacturing and packaging process begins at the company's plant in Hunt Valley, MD, where the product is manufactured to exacting specifications.

"All materials have been processed and milled to meet chemical, physical and micro specifications," says Dave Grimshaw, vp of operations for McCormick Canada. The processed materials then are shipped in bulk to Ontario in returnable totes that weigh approximately 350 kg.

Empty bottles are fed into a New England Machinery Inc. unscrambler through a bulk hopper. The unscrambler orients the bottles and lanes them for travel in a single file to an Accraply 306 labeler. The labeling station represents one of the upgrades in the filling line.

"Another complexity is the variety of labeling materials used on this line. We need to ensure that all of these labels can be applied to our proprietary, square-pedestal bottle," Grimshaw remarks. "The new spice labeling is a single layer clear polyolefin, and on the same line we also pack seasoning blends that have multilayer, peel-back labels."

The Accraply 306 can apply more than 100 labels/min. The stepper driven, push/pull web drive with automatic product speed following, has a maximum dispense speed of 2,300 in./min. The 16-in. label roll unwind uses a dancer arm for tension control, and the stepper driven rewind is collapsible.

Spices are fed from the bulk totes on a mezzanine via a Kason Corp. vibro sifter into a surge hopper.

Facing key challenge

Explaining a key challenge when packaging spices, Grimshaw says: "The most significant challenge that we encounter is ensuring the line is capable of maintaining performance expectations while accommodating the wide range of physical characteristics that spices and seasonings present. Particle size, structure-flake versus granule-and bulk density vary greatly. The filling equipment must accommodate the entire product range."

A PneumaticScaleAngelus Mateer rotary filler with twin volumetric augers is used to dispense product at a nominal speed of 140 bottles/min. To ensure proper fills, a Thermo Fisher Scientific Inc. checkweigher is used to measure the amount of spices in each bottle and provide feedback to the filler, which adjusts the fill weight automatically.

Garvey Corp. table-top chain conveyors are used to shuttle packages between packaging line equipment.

unitization and tray loading

Filled bottles travel single-file from the filling area to a Douglas Machine Inc. automatic case/tray maker. A servo-driven lane divider divides the bottles into two lanes as they are conveyed to a tray loader. The case/tray maker erects a tray, loads six filled bottles into each tray.

Filled trays move to another lane divider that feeds the unitized packages into an EDL Packaging Engineers Inc. shrink tunnel. Trays are wrapped two at a time. Both the tray maker and the shrink tunnel represent upgrades to the Ontario filling line.

Outer shipping labels are applied on two adjacent sides of the shrink-wrapped packs by a Domino Amjet Inc. unit. The packs are manually palletized. Product pallets are stretchwrapped by a Lantech semi-automatic stretchwrapper.

Each wrapped pallet then receives a manually applied label, is loaded onto a truck and then shuttled to a distribution center.

In addition to maximizing product filling and packaging efficiencies, the spice packaging line also is designed with consumer safeguards. "We look for both ferrous and nonferrous metals at multiple points of the overall process," says Ainslie McKinnon, an engineering manager for McCormick. This is done by a Mettler-Toledo Safeline metal detector.

Each bottle also is date coded by a Videojet Technologies Inc. Maxum printer prior to filling.

Team effort

"This was a major change for McCormick Canada," says McKinnon. When asked about key team members, McKinnon exclaims, "There are too many others to name!" and acknowledges the complete engineering and manufacturing teams for their collective hard work.

It seems fitting that McKinnon would want to acknowledge the team efforts of McCormick employees. After all, it was a collaborative approach that brought success to the packaging update project with packaging operations and package design both playing important roles.

Consumers can purchase the redesigned McCormick Club House Core spices and seasonings at major grocery stores across Canada. At time of publication, the product range was sold at a manufacturer's suggested retail price of between C$2.19 and C$8.49.

Accraply, a div. of Barry-Wehmiller Cos Inc., 800/328-3997. www.accraply.com

All Stick Label Ltd., 800/263-2368. www.aslprintfx.com

Berry Plastics, 812/424-2904. www.berryplastics.com

Domino Amjet Inc., 847/244-2501. www.dominoamjet.com

Douglas Machine Inc., 320/763-6587. www.douglas-machine.com

EDL Packaging Engineers Inc., 920/336-7744. www.edlpackaging.com

Food Marketing Institute, 202/452-8444. www.fmi.org

Garvey Corp., 800/257-8581. www.garvey.com

Ipsos, +33 1 4198 9000, www.ipsos.com

J. L. Clark, 815/962-8861. www.jlclark.com

Kason Corp., 973/467-8140. www.kason.com

Lantech, 800/866-0322. www.lantech.com

Marovino Visual Strategy Inc., 416/503-0676. www.marovino.com

Mettler-Toledo Safeline, 813/889-9500. http://us.mt.com

New England Machinery Inc., 941/755-5550. www.neminc.com

Novellus HQ, 416/291-3433. www.ng-sys.com

Optiscan Pty. Ltd., +61 3 9538 3333. www.optiscan.com

PneumaticScaleAngelus, 330/923-0491. www.pneumaticscale.com

Thermo Fisher Scientific Inc., 800/678-5599. www.thermofisher.com

Videojet Technologies Inc., 800/843-3610. www.videojet.com

Wright Lithographing Co. Ltd., 519/434-3233. www.wrightlithographing.com

About the Author(s)

You May Also Like