Quintus Technologies’ move back into the high-pressure processing (HPP) spotlight is a natural one.

January 24, 2022

It turns out that high-pressure processing (HPP) systems provider Quintus Technologies wasn’t retired, it was simply awaiting the right time to reappear on the HPP equipment stage.

“Quintus Technologies has identified a need in the food industry market for improved options for HPP systems and services,” says Jan Söderström, CEO and president of the Sweden-based company. “As the former manufacturing and engineering arm of Avure Technologies, and with our core competency and rich history in high-pressure applications, it’s natural that we once again bring our expertise to this arena.”

Not only is it returning to the market, Quintus is an HPP pioneer, involved in the technology since 1953.

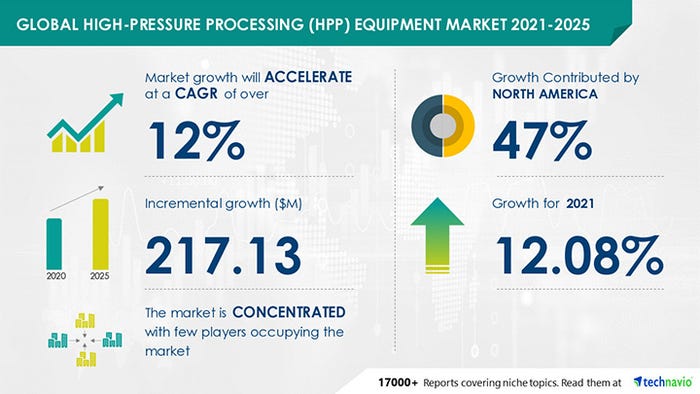

The timing to reentry seems fortuitious as HPP-pasteurized products attract growing consumers interested in flavorful, healthy foods and beverages low in additives and high in nutritional value. The HPP equipment market is likewise on a healthy upward trajectory at 12% CAGR forecast from 2021 to 2025, according to a report released in September 2021 by Technavio. That represents an incremental dollar value of more than $217 million over the period.

Quintus Technologies’ position in the market is anchored by a portfolio of innovative new HPP equipment and customized service solutions. The company’s equipment is engineered for prepackaged products in packaging including plastic bottles, trays, pouches, tubes and other formats that have some degree of flexibility to withstand the extreme pressures involved.

Ed Williams, the company’s general manager, Americas, responds to Packaging Digest’s questions in this exclusive interview.

Why did the company exit the market?

Williams: It was a decision taken under the ownership of Milestone Partners, a private equity firm. Avure was divided into two fully independent global platforms — one focused on HPP systems for packaged food under the Avure brand, and the other focused on metal densification systems and sheet-metal forming systems under the “Quintus” brand for aerospace applications and other industrial markets.

Why is the timing good for reentry?

Williams: Quintus Technologies has identified a need in the food industry for improved options of HPP systems and services. As the former manufacturing and engineering arm of Avure Technologies, and with our core competency and rich history in high pressure applications, it is natural that we once again bring our expertise to this arena.

What’s the state of the global market for HPP?

Williams: We foresee continued growth for the HPP market for the coming decades. HPP is recognized globally as the premium minimal-processing technique that enables the production of safer, preservative-free refrigerated foods and beverages with superior nutritional benefits and taste.

Surging from novel to mainstream technology in less than a decade, HPP has become an ideal method for processors to protect their brands against recalls, develop new products, extend shelf life, enhance quality, and boost profitability.

What consumer trends play to the technology's strengths?

Williams: Today’s consumers are more in tune with global health issues such as foodborne illnesses, sodium intake, and consuming highly processed foods. By not having to rely on thermal pasteurization and chemical preservatives, HPP offers consumers fresh, safer, minimally processed, natural-tasting products with higher nutritional values and clean, easier-to-understand labels.

Which geographical markets will you prioritize?

Williams: We see growth potential in all geographical markets. We believe that the business will be evenly distributed, one-third each, for our three main markets, Europe, the Americas, and Asia.

Please compare the US/NA market with overseas markets.

Williams: Given historical context as well as market size, the commercial market for HPP products in NA is more evenly distributed than what we have observed in other markets such as Asia, EMEA, and Central/South America.

For example, current predominant HPP applications in Asia are beverages and meat products.

By comparison, HPP applications in NA are well distributed among meats, beverages, seafood, ready meals, and a wide variety of plant-based products including guacamole, hummus, salsa, and ready-to-eat salads.

What’s an emerging product category for HPP currently?

Williams: Important application sectors to focus on include juice and beverages, meat products, plant-based foods, and ready meals.

Who’s your target customer?

Williams: Food manufacturers including start-ups, regional and national companies, co-packers, and HPP contract service/tolling centers.

When might the first system be installed?

Williams: Our first modular product installation — for the QT 150L (seen in the video above)— will be installed in Q1 2022 in the US. That will be followed by an industry event at our newest Application Center in Columbus, OH.

Our second installation, featuring the same modular product, will ship sometime in Q2 2022.

Tell us more about the QT 150’s capability.

Williams: The QT 150L modular model offers companies the ability to enter HPP production with the appropriate capacity to meet their immediate needs and the flexibility to quickly expand capacity as business grows. Depending on a company’s packaging, processing conditions, and selected modular configuration, the QT 150L can process as little as 500 pounds to as much as 2,200 pounds per hour.

What’s a misconception about HPP you can clear up?

Williams: Maintenance upkeep, operational costs, and availability of parts have often been identified as issues that require ongoing attention. Quintus Technologies is addressing these concerns through improved product design features, and the inclusion of our Quintus Care Program with every new HPP installation. The Quintus Care Program is designed to help food companies create a hassle-free HPP operation by reducing unscheduled downtime and freeing up capital otherwise tied up in parts inventory, while securing ongoing professional HPP Technical Services and HPP Applications Support. The backbone of the Quintus Care Program is frequent and regular equipment reviews by skilled Quintus technicians.

What is a typical time for a batch?

Williams: Depending on customers’ specific applications and which QT 150 modular configuration is used, a complete typical batch takes approximately 5 to 8 minutes.

What’s the most important thing for a potential customer to know about your equipment?

Williams: Quintus press offerings have newly integrated mechanical and digital solutions, which are accompanied by comprehensive application know-how, and best-in-class after-market technical and application support, our Quintus Care Program. The food science experts at our HPP Application Centers in the US, Sweden, and China will be available to advise processors on everything from ingredient choices to optimizing processing parameters for maximum ROI.

What services will you offer at your Application Centers?

Williams: We support the customers throughout the complete HPP development process. From recipes to packaging to designing and providing in-house validation services (as they may require for regulatory needs), our comprehensive evaluation and support is geared for getting their product in the market quickly.

You May Also Like