January 29, 2014

|

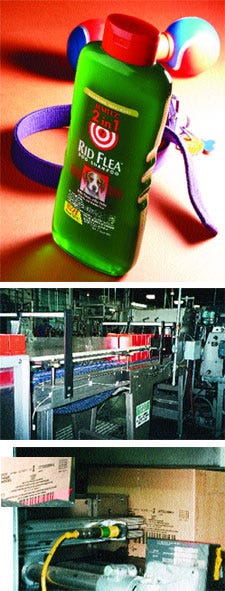

Shelf cartons, middle photo, each holding three 18-oz bottles of dog shampoo, convey downstream to the caser, where one shipper accepts four cartons. Highly legible data, above, from bar code to pallet-pattern bitmap diagram, are printed at rates to 100 ft/min by the new coders. Immediately following printing, above, inset, the impression is checked out by a scanner preceding packoff to automated palletizing. |

Hartz Mountain Corp. is keeping ahead of the pack by placing its paws more precisely. In its Bloomfield, NJ, headquarters plant, the pet products marketer is in the process of upgrading its case-marking capabilities and linking them within a single data leash for improved control and efficiency.

Installing a series of new ink-jet printers since last November, Hartz Mountain is systematically phasing out obsolete equipment at the bottom of its packaging lines that was rapidly going to the dogs, PD learns from George Engel, corporate engineering vp, and Ted Sadej, packaging maintenance manager, during a recent visit.

"We're replacing the older printers at the rate of one every two to three weeks on our high-volume lines," Engel says.

"Seven are converted in this plant, with six additional to go, plus three in our Ohio operation and one in Indiana," he adds. "With the older machines, we were getting no better than eighty-percent reliability. We've gone way beyond that now and see other benefits, too."

One is a savings of 4 cents per case in labeling. Another is the reduced need for manual involvement, with six fewer people needed in the Bloomfield plant alone. A third is higher output. All result from the change from manually applied, in-house-printed pressure-sensitive labels.

The second user

By adopting the new printing system, the HSAJet-5000 from HSAUSA and distributed by Dartronics, Hartz Mountain becomes the second American marketer to use it. Part of HSAUSA's Image Maker series, the 5000 is rated at 100 ft/min, with an unusually high 180-dpi vertical and 360-dpi horizontal resolution.

Ink feeds from 500 independently addressable jets at the digital print engine, the Xaar-500, standard to the HSAJet installations at Hartz Mountain. Its maximal character size is 2.8 in. from a single printhead.

At Line A, the most recently installed system in the plant's liquids packaging area, Ted Sadej cites the simplicity of installation and low maintenance of the equipment. "This is a pretty sophisticated product, but everything about it is easy to use," he comments.

|

At the caser, magazine-fed wraparound shippers are now unmarked?one of the gains of the printer changeover in the liquids packaging area. |

During PD's visit, the line was packaging 18-oz quantities of Hartz® 2 in 1® Rid Flea™ dog shampoo with pyrethrin into clear vinyl bottles produced by Spentech Plastic Containers. Because of proprietary features in the filling, capping, labeling and cartoning equipment, Hartz Mountain declined to provide information on these systems. But Engel does inform PD that the oval closure, integrally hinged with a reduced orifice for flow control, is injection-molded of orange polypropylene by Zeller Plastik. It is color-matched to the logotype of the p-s face label from CCL Label, which also converts the back label.

Getting together

Following the upstream functions, three bottles are automatically grouped and inserted into a glued-end, die-cut folding carton from Universal Folding Box. This is the standard shelf pack, and it feeds downstream into an Arpac wraparound caser, which groups four-carton quantities and end-seals the 32-ECT corrugated shippers from Smurfit-Stone with Henkel hot melt, fired from Nordson applicators.

Cases discharge, oriented in the length direction, to the infeed of the jet printer, which is activated as the cartons pass a Banner photoelectric eye, standard for all of the installations of the HSAJet-5000. The data printed on the shipper includes a quantity statement in English, French and Spanish; a product description and source; a bar code; and a bitmap diagram for the palletizing pattern, reducing inventory needs and heading off potential mistakes.

After printing, the shippers pass by a MicroScan 850 from MicroScan Systems, common to all of the HSAJet-5000 installations at Hartz Mountain and integrated by the printer supplier, PD learns from Kenneth A. Darrow, HSAUSA's managing director.

Through the system's stainless-steel-encased controller–like a tail that wags several dogs–"Hartz Mountain is able to dynamically download via Ethernet a database" to its own controllers on a daily basis, Ken Darrow explains. "The software used to design the template links to the information stored in the database," he adds.

Thus, the operator needs only to scan the UPC on the container going into the case; the template fields are then populated with information obtained from the database. An automatic search is activated by the scan, with the appropriate record found. A pointer, locking on to that record, loads the template with the information and prompts the operator to enter an extension for the bar code and to activate the printer.

The system, Engel says, works off of Hartz Mountain's IBM computer. "It's flexible enough to extract data from the corporate database, and helps us obtain better control over package flow and materials than we've had before.

"We've been able to progress in case consolidation, since we now can use unprinted master shippers. And those we use are more legible through the much higher resolution. Our old printers had no better than a sixty-four dots-per-inch capability."

To this, Sadej adds: "In the months we've had this equipment in place, operation has been smooth, even when we went to two-shift days to handle spring to early summer volume requirements. It's nice not to have something to complain about."

It's better than that. It's the cat's meow.

More information is available:

Case printer: HSAUSA/Dartronics, 800/298-8936. Circle No. 217.

Bottle: Spentech Plastic Containers, 804/222-6030. Circle No. 218.

Closure: Zeller Plastik, a Crown Cork & Seal co., 847/247-7900. Circle No. 219.

Labels: CCL Label, 800/423-6539. Circle No. 220.

Carton: Universal Folding Box, 201/659-7373. Circle No. 221.

Caser: Arpac, 847/678-9034. Circle No. 222.

Shipper: Smurfit-Stone Container Corp., 888/801-2579. Circle No. 223.

Adhesive: Henkel Adhesives, 847/468-9200. Circle No. 224.

Applicator: Nordson Corp., 800/683-2314. Circle No. 225.

Photoelectric eye: Banner Engineering Corp., 888/373-6767. Circle No. 226.

Scanner: MicroScan Systems, 800/762-1149. Circle No. 227.

Computer: IBM, 800/426/4968. Circle No. 228.

About the Author(s)

You May Also Like