January 29, 2014

Unilever's Pond's cold cream jar packaging operation in Ciudad Industrial del Valle de Cuernavaca, Juitepec, in the Morelos state of Mexico, is making its way to inspection perfection with an economical, high-performing label-inspection system, the Series 600 SmartImage from DVT Corp. Installed in pairs this year on three jar-packaging lines, the Series 600, Model 630 system was provided in Mexico by local integrator, or ASP (automation solution provider), Fabrica Inteligenté.

|

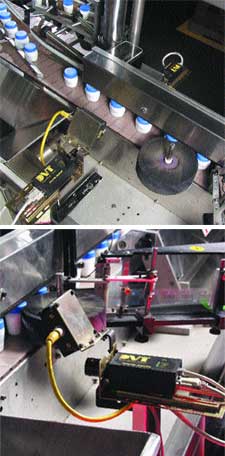

Jars travel on a conveyor past the inspection system, top photo. The sensors immediately follow label application and check jars for proper application and orientation of the transprent front/back labels. Closeup, above, shows one of three pairs of sensing systems on cold cream lines running assorted jar sizes at Unilever?s Mexican operation in Juitepec. |

Unilever's Pond's Division says it wanted reliable sensors for three jar-filling lines so that it could check for the presence and proper positioning of clear-film front and back pressure-sensitive labels applied to several polypropylene jar sizes of Pond's cold cream. Lines 5, 6 and 7 run different cold cream products in capacities from 30 to 450 g. Once filled and capped, the jars are labeled automatically and are then immediately scanned by the SmartImage system to verify the label's presence and to check the bar code printed on the label in-line.

The sensors replace a manual label-inspection process,, Unilever de México packaging engineer Edgardo J. Ramirez informs PD: "As part of the jar label inspection process, we used to have people on the lines checking for imperfections. They would then have to separate jars with any labeling defect from acceptable jars. The risk was often in the speed of the labeling machine."

The machines run at about 80 jars/min, which is a fairly low speed, Ramirez indicates, but is fast enough "that a jar could pass through the line mis-labeled using the previous inspection method. There would be a serious problem [out in the markteplace] if a jar was labeled improperly or not at all. But personnel found the manual process uncomfortable and it was difficult to avoid a mistake one-hundred-percent of the time."

The goal was to find a vision system that could provide 100-percent inspection of the labels at line speeds and to check label placement both vertically and horizontally, alerting operators to incorrectly applied labels. "We also use these sensors to read bar codes on the jars," the engineer says. "These systems work so efficiently, we're so far finding more than eighty percent of the defects on Line seven and will soon detect the remaining twenty percent, once we evaluate all of the system's formats. The jars pass our quality standards. That's very important. Some of our most successful products are the cold creams," he observes. "We distribute them nationally here and export them to South American markets. They have to arrive in the stores looking perfect."

The company evaluated many inspection alternatives, Ramirez says, including some mechanical options, inductive sensors, cameras, and even adjustments to the labeling equipment.

The plant ultimately decided on the compact SmartImage series, which consists of a pair of sensor heads mounted inches above the filling line conveyor. Integrated into each head is a SmartImage digital sensor, linking network communications (Ethernet and fieldbus), image-acquisition electronics and DVT's Windows®-based computer user interface, FrameWork 2.3 software. Each unit is integrated with a camera, image-acquistion electronics and a computer, to allow dynamic access to a CCD without image float or flutter. Fabrica Inteligenté also supplied the SmartImage units with a micro-programmable logic control unit, a power supply, a display monitor and selection of Unilever-validatable software formats geared to all of the jar and label configurations.

"We chose DVT sensors because they were economical and really fit the application space limitations. They also work well on the packaging lines. They are the best solution to this kind of problem," Ramirez tells PD.

|

The compact sensing units incorporate an embedded PC processor and microprogrammable logic control unit. They were also supplied with a power supply and image-acquisition technology to maintain optimum image stability and repeatability. |

With a resolution imaging capability of 640 x 480 pixels, the pairs of sensing systems on each line simultaneously inspect the front and back label on each jar, immediately after the filled, capped jars are labeled on p-s labelers from Avery Dennison. With subpixel measurement and mathematical computation as part of the program, quick detection of unacceptable labels is reported along user-defined inspection paths tied into discrete outputs that are reported back to the micro PLC. The system delivers control data such as quality-control inspection results, and can coordinate information for motion controllers, statistical process control data and even two-dimensional code verification. The two sensing units each have a footprint measuring only 1.6 x 2.2 x 4 in. They each also incorporate an embedded Power PC processor and image acquisition technology to maintain optimum image stability and repeatability.

For the moment, case packing on these lines continues to be a manual function, Ramirez explains. But that may change. "We are buying equipment for a new packaging line that will reach speeds of 200 jars a minute, so we will re-adjust these sensors to accommodate Krones Autocol labelers."

"After installation, we were able to start scanning all labeled jars and correct any errors from the labeler," Ramirez tells PD. "With this system, the line runs more efficiently because we can correct problems on-the-fly."

More information is available:

Inspection sensors: DVT Corp., 770/449-4960. Circle No. 221.

Systems integrator, technical support: Fabrica Inteligenté, 777 3 12 38 78. Circle No. 222.

P-s labelers: Avery Dennison, Printer Systems Div., 800/395-2282. Circle No. 223.

P-s labelers: Krones, Inc., 414/ 409-4000. Circle No. 224.

About the Author(s)

You May Also Like