Four industry insiders unpack the innovations for applying full-body labels amid demand for thinner films, higher speeds, quicker changeovers, and reduced carbon footprint.

November 25, 2020

Full-body shrink-sleeve labels wrap rigid containers of all sizes and shapes to provide the greatest possible canvass for graphics and information. They also offer great promotional and marketing flexibility while streamlining container inventories. When it comes to automatically applying these labels, innovations in materials are driving new challenges for packaging machinery.

In response, builders of shrink-film labelers are responding to demand for their machines to handle thinner films and faster changeovers, and with greater sustainability. Innovations range from mechanical upgrades to advanced software controls and management tools that brands can coordinate with related equipment on the line, such as banding, accumulators, and tunnels.

Four industry insiders participated in a virtual roundtable on the topic:

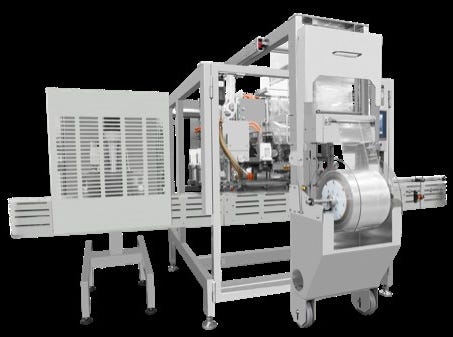

Ed Farley, product line manager with Axon, a ProMach Co.

Richard Howlett, product line leader for Accraply, a Barry-Wehmiller Packaging Co.

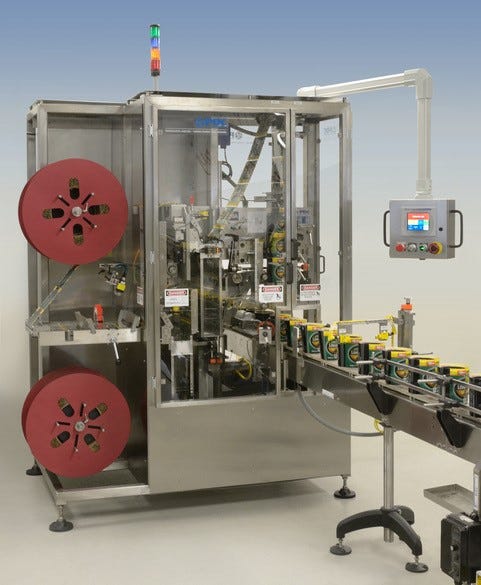

Rich Keenan, national sales manager, PDC International

Matt Linz, vice president of sales, Tripack

Below you’ll find their insights on the latest advancements, benefits, challenges, and future developments for shrink-label applicators. (For a related primer on shrink tunnels, see “Which Shrink Tunnel is Best for Your Labeling Operation?”)

What recent advancements have you seen in shrink-label applicators?

Farley: A recent advancement is the ability to run ultra-thin gauge sleeving materials. Axon’s SLX system is equipped with our patented SLT technology and, when paired with a zero-tension film feeding system, can run film as thin as 25 microns at production rates of up to 800 containers per minute.

Howlett: The shrink-sleeve film market is very dynamic with new and more advanced shrink films being developed continuously. These advancements are certainly having an impact on shrink-label application machines.

The most significant trend that we see is the down-gauging of shrink films. This has an impact on the design of shrink-sleeve application machine cutting system. The cutting systems are now required to cut thinner, softer films at higher speeds.

Keenan: We have been making improvements in design and features to address customer issues on a few fronts.

First, with more companies using unskilled labor, we’re offering features for easier, quicker startup and changeover for greater uptime.

Second, we’re helping customers better address downtime due to failure of wear parts, which has a major impact on your overall equipment effectiveness (OEE) and total cost of ownership (TCO).

Finally, we’re working with folks on ways to reduce the carbon footprint of their machines without affecting performance.

Linz: As a company focused exclusively on the shrink-sleeve labeling and packaging industry, we are continuously pursuing advancements to our equipment solutions with a focus on performance, reliability, and operator adaptability (PRO). Most recently, Tripack is developing new technology that allows the equipment to expand and contract with the flow of the lay-flat (LF) film web. This advancement in equipment technology dramatically improves the relationship between film and equipment.

In addition, we’ve created ergonomically friendly film accumulation solutions that enable operators to continuously run their lines without stopping to perform film splices.

How do these advanced systems compare to the existing standard equipment?

Linz: Tripack’s equipment works within the industry standard mandrel LF tolerance of +/-1 millimeter. Our unique mandrel design will help compensate for occasional film size fluctuations resulting in reduced application failures and greater productions efficiencies.

Howlett: With the trend to cut thinner, softer films at higher speeds, control of the shrink-sleeve during the cutting cycle is critical. These systems generally use the most advanced controls to allow maximum control of the sleeve during the cutting process. With the need for control being paramount, we see the need to monitor OEE in the form of advanced data-gathering and diagnostics. To achieve this, “smart” human-machine interface (HMI) technology is used in many shrink-sleeve application machines, giving the end user full transparency and understanding of how their shrink-sleeve system is performing.

Farley: The film thickness standard in the US in most cases is 50 microns. Most mandrel-style systems can accommodate film thicknesses down to 40 microns for less challenging applications. Handling film below 40 microns becomes an issue for most systems due to the lack of stiffness in the film, making it difficult to advance and apply to containers.

Keenan: For customers who might not need frequent changeovers, our standard equipment would be a good fit. But for others, we have addressed quicker changeovers on some of our models, especially for those using unskilled labor.

To reduce changeover time, we are now offering a Power Height Adjustment with linear transducer. Because this is menu-driven in the HMI, you can push a button and the applicator head will raise to a pre-set location. Also, you can have the inspection unit and heat tunnel all raise at the same push of the button. Eliminating these physical adjustments, in turn, reduces changeover time.

To take it further, this same push of the button can change all electrical adjustments; line speed; the photo-eye used to separate the shrink sleeves; and the heat tunnel temperature.

As to removing our mandrel during changeover, which requires a person, we are now using self-centering units with digital positioning indicators. Customers asked if we could take this further, since there have been issues with folks who weren’t adept with this process during changeovers. We have installed a torque wrench-style device, so the dial indicator will not over-tighten the changeover even if an operator fails to pay proper attention. Working closely with our customers is what drives our improvements.

Another advance is the way we address downtime to replace wear parts, which is a major contributor to total cost of ownership and your OEE. One example can be seen in advances we’ve made in cutting-blade design. There are many in use that will last one or two weeks, which is detrimental to both your TCO and your OEE. Instead, we have made some adjustments in our design over the years that address this. As a result, today, data from our customers show 20 to 25 million cuts before the blade set has to be removed and sharpened. Plus, there is less than a 5-minute change time, with adjustments made before you’re up and running.

What are the benefits of these advancements for packaging machinery buyers/users?

Keenan: Many of the benefits come down to uptime on the packaging line and overcoming lost time during changeover and start-up. Now that changeover is performed with a push of a button, which always goes back to the factory setting, in a very short time, this will reduce issues associated with a changeover.

And as I said earlier, greater longevity on wear parts along with quick and simple replacement can only help your OEE and TCO.

Linz: A cohesive relationship between the film converter and equipment manufacturer is key for any end user. Tripack’s recent technological advancements further develops that relationship, while giving end users and brands the flexibility to select film converters of their choice.

Farley: Thinner films translates into less packaging used, which is beneficial from a sustainability as well as a cost standpoint.

Howlett: The benefit for the buyers/users is that if the correct sleeve-application machinery is selected, then the machinery will be advanced enough to cope with the trend of cutting thinner, softer films at higher speeds, thus opening up the market for the user to use a wider range of shrink films and offering more options to brand owners, with thinner films reducing weight and volume for logistics, and reducing CO2 emissions.

What areas in shrink-label applicators still need work and why?

Howlett: The areas of a shrink-label system that are being worked on are that part of the system that can be deemed the most challenging, which are the shrink tunnels. With the continued advancement in shrink film, shrink tunnels are equally important parts of the process and are being advanced in technology in the pursuit of providing the perfectly finished shrink-sleeve labels. Selecting the correct tunnel is critical to produce the best possible final appearance of the product. [Editor’s Note: See Howlett’s guidelines in “Which Shrink Tunnel is Best for Your Labeling Operation?”]

Keenan: A lot of what we have been hearing from our customers is about the carbon footprint. We have already, as a standard, gone with high-efficiency motors, and we use almost no shop air. We continue to look at ways to reduce power to our dry heat tunnel. As for our steam tunnels, some of our models are now using very low pounds per square inch (PSI) of steam vapor.

Farley: Almost all shrink-sleeve labeling machinery is not designed to be used in wet or washdown areas. This is due to many factors — mainly cost-related.

Linz: Communication and planning between film converter, equipment manufacturer, and end user continue to be an area of opportunity. Toward that end, our consultative approach focuses on ensuring an end user is always set-up for success at production start-up.

What’s next and when might we see further improvements in shrink-label applicator machinery?

Keenan: What’s next? Faster single-head applicators exceeding 800 containers per minute, low carbon footprint, and an overall smaller footprint. At some point, we will be announcing our next-generation high-speed applicator.

Linz: We are pushing research and development (R&D) improvements every day. Tripack is a big advocate of simplistic design and user/machine interface. Future equipment improvements will focus on making changeovers easier and quicker.

Now it’s about fine-tuning — how reducing one more adjustment or improving calibration settings can promote quicker, easier, and more reliable changeovers. Uptime equals profits. It’s all about uptime.

Farley: Axon introduced a new line of washdown tamper-evident banding and shrink-sleeving machinery at Pack Expo Connects. The HydroTech line will include machines with food-grade washdown, servo-motion control, and all stainless steel construction. [Editor’s note: This line was included in our flexible packaging highlights from the PEC event.]

Howlett: As the industry continues to keep a watchful eye on sustainability and the carbon footprint, the industry may make improvements in ways to shrink the sleeves using less energy and with more use of renewable energy.

About the Author(s)

You May Also Like