January 29, 2014

Amatix Packaging Supplies of Sun Valley, CA, is giving laser toner and ink-jet cartridge products a second chance at making a first impression. Established in 1989 and now a subsidiary of sheet-fed converter Marfred Industries, the company occupies a unique and successful niche, supplying stock cartons, die-cut inserts and master shipping cases to producers of remanufactured laser toner and ink cartridges.

The brainchild of a toner cartridge recycler, the business sprang from the manufacturer's desire to give his product packaging a more upscale appearance. Instead of the typical plain, brown box traditionally used for such products, he began using cartons printed with basic, one- and two-color designs. "He soon discovered that the market for his packaging was probably better than the market for his printer products," says Amatix general manager, Richard Cohn. "There are a wide variety of companies, from mom-and-pop shops to mass-market, diversified producers, that don't have the desire or the means to create artwork, buy plates and commit to production-run quantities of packaging, especially for unique products and specialty applications."

Today, customers can select from a range of package sizes and styles designed to set a variety of "tones." Entry-level lines made from recycled materials convey environmental friendliness, "a very positive message for some segments of the market," says Cohn.

Top-of-the-line, litho-laminated packaging offers a more professional image, important to those segments competing with office supply stores and catalog distributors. But whether simple or sophisticated, Amatix' product lines can be quickly tailored to meet changing customer requirements, given the company's unique relationship with its sole packaging converter, parent company Marfred. And, quality is assured, given Marfred's latest investment in a new Automatän litho label laminator.

Technology is key

Founded in 1964, Marfred Industries today is a third-generation, family-owned business specializing in both the converting and distribution of paperboard-based packaging and shipping supplies. End-use markets include cartons and cases for a wide range of industrial products and consumer goods. Six facilities are located across the Los Angeles area, while a Las Vegas warehouse handles the growing south Nevada market.

Company managers attribute Marfred's steady growth to a commitment to new technology. Since 1997 alone, the company has invested $3.5 million in new equipment. And, through a 15-month development cycle and a $400,000 investment, its previously static website has recently been replaced with one offering customers the ability to shop online.

Another slick investment was the purchase of Amatix from its founder seven years ago. According to Cohn, since he joined the company three years ago, Amatix has doubled its sales and has branched out to serve international markets, as well. Broadening its product selection, the company offers approximately 350 stockkeeping units comprising all types of items used by recycled toner cartridge manufacturers. "In addition to packaging supplies, we offer a complete line of cleaning and consumable products, cloths and wipes, and different types of chemicals," notes Cohn. "We sell safety products, gloves and face masks–virtually anything they would use from the time they disassemble a product until the time it goes out on the UPS truck, and everything in-between."

A broad product line

Making up approximately 100 of Amatix' 350 skus are its stock cartons and corrugated inserts. These include .020 chipboard folding cartons measuring 31/4 x 113/16 x 41/4 in. and corrugated cartons from 113/4 x 51/2 x 33/16 to 181/8 x 73/8 x 11 in., with 15 sizes in-between in four different designs. Printed master pack shipping cases are also offered, ranging from 16 x 6 x 91/2 to 241/4 x 181/2 x 231/2 in., that can accommodate various quantities of Amatix stock cartons. Designed with die-cut, snap-lock bottoms and tuck-type tops that do not require taping, a line of local delivery boxes can be re-used by the cartridge manufacturers for multiple delivery cycles.

|

Kraft board is fed into the laminator to be joined with label stock, preprinted via offset printing. |

Amatix' carton lines address an array of customer needs in terms of design and cost. An entry-level line consists of one-color, flexo-printed kraft cartons. Mid-level packaging comprises #1 and #3 white cartons, offset-printed in two colors. Also under development is a new line of cartons utilizing International Papers' LCL (Lightly Coated Liner), a high-holdout, clay-coated glossy linerboard designed for high-end printing. The line will include direct-print, two-color cartons that Cohn says will provide the sheen and gloss of litho lamination, but will retain the cost-effectiveness of a flexo-printed job. High-end products include several lines of three- and four-color litho-laminated cartons that offer a more professional image.

|

Laminated carton stock exits the laminator. |

Design concepts are initiated by Cohn and are fine-tuned by Marfred's in-house design team. "I don't have an art or design background," says Cohn, "I observe what the OEM and major manufacturers are doing with their packaging, and I try to key-in on some of their basic design elements, while at the same time, creating a different, professional look."

Laminator offers versatility, speed

Making sure the retail-comparable designs visualized by Cohn for Amatix' top-level products are fully realized in the finished product is the job of Marfred's Corrugated Container Div. in Lakeview Terrace, CA. A 105,000-sq-ft plant with 160,000 sq ft of additional warehousing space and employing 130 people, the facility specializes in custom corrugated converting, providing printing, die-cutting, litho-laminating, and specialty folding and gluing services. With the addition of an Automatän Model 4260 litho label laminator in April '00, the plant is capable of adhering spot-, full-, panel- and strip-mount litho-printed labels to corrugated sheets of virtually any flute configuration.

Providing background on the purchase of the 4260, Randy Phares, Marfred plant manager, says, "With the litho labeler we used previously, we could only run full-litho labels; we couldn't run a spot-litho job, which prevented us from getting some types of business. Since we purchased the new machine, we've grown our litho laminating business significantly. In fact, this year we've already run considerably more jobs than we did during all of last year." Between the two machines, Marfred can now run labels as small as 6 x 8 in. to as long as a 50 x 80 in.

Featuring automatic label and board feeders, the Automatän also reduces labor and increases productivity. Running at 5,500 to 5,600 pieces/hr, the machine quadruples the speed of Marfred's other laminator, a hand-fed unit, which outputs 1,000 pieces/hr. "Both of the machines operate at approximately half that speed," notes Phares. "But, that's still significantly faster."

And "you can achieve a lot higher quality, because it holds registration much better," he adds. Amatix litho-laminates its high-end products because the process enables sheets to be printed at a 150-line screen, providing a much more refined image versus the 65-line screen achieved with direct flexo printing on corrugated.

|

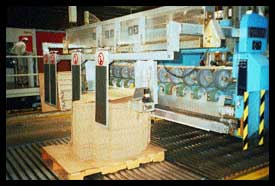

Laminated cartons are fed through a rotary die cutter. The rotary die, wrapped around a black, steel cylinder, is visible in the right-hand corner of the picture. |

On the day of PD's visit, the plant was litho-laminating and die-cutting a full-panel, 161/2 x 97/8 x 43/4-in., four-color carton job from Amatix. While many of Marfred's litho label projects are printed in-house at its Folding Carton Div. in North Hollywood, CA, this job was done by an outside vendor. Measuring 39 x 39 in., the label fell outside the maximum image size of 28 x 40 in. accommodated by Marfred's seven-color, 40-in. KBA Planeta sheet-fed offset press. During lamination, the printed, 80# C1S label stock from Monarch Litho is applied to a 200# B-flute kraft substrate, supplied by vendors that include CorruKraft and Smurfit Stone, using a standard Dextrin-based laminating glue from Applied Products.

|

Cartons discharge from the die cutter onto a pallet, ready for stretch wrapping and delivery to Amatix. |

Finishing touches

After laminating, the Amatix carton was die-cut at 6,000 pieces/hr on a four-color Martin 66-in. DRO 1628 rotary die-cutter from Bobst equipped with a Martin stacker from the Geo. M. Martin Co. that strips away scrap. According to Phares, the practice of rotary die-cutting litho-laminated stock is somewhat unusual in the converting industry. "If you run the machine too fast or have excessive pressure, or if the box starts to slip a little in the machine, then the box size can vary slightly and some other quality problems can result," he explains. Marfred's success with this method, he says, is the result of the specifications it sets forth for its die manufacturer, combined with operator skill.

Amatix' direct-print jobs are printed using the flexo printing capabilities of either its Martin DRO 1628 or its Bobst SP0 160S Autoplatenw die cutter, which offers a flat die board and a maximum speed of 5,500 pieces/hr. Amatix' jobs requiring gluing are run on Marfred's Post 1080 folder/gluer, also from Bobst, at speeds up to 12,000 pieces/hr. In addition to standard box styles, the machine can also glue autobottoms and cartons with built-in dividers.

Affirms Richard Cohn, Amatix occupies a unique niche indeed, and one that is made possible by the broad array of services provided by its parent company. "The advantages of being owned by a packaging manufacturer are vital to us, because all the R&D, graphic design, etc., can be done in-house." And, with the ability to turn product around faster, Marfred greatly facilitates Amatix ability to meet its customers' growing demands for JIT distribution. These benefits combined bring custom solutions to a generic market.

More information is available:

Sheet-fed converter: Marfred Industries, 818/896-0550.Circle No. 257.

Litho label laminator: Automatän, Inc., 715/341-6501. Circle No. 258.

Linerboard: International Paper Co., 800/223-1268. Circle No. 259.

Offset press: KBA North America, 802/878-9400. Circle No. 260.

Label stock: Monarch Litho, Inc.,323/727-0300. Circle No. 261.

Label stock: CorruKraft, 714/562-6002. Circle No. 262.

Label stock: Smurfit-Stone, 314/746-1100. Circle No. 263.

Adhesive: Applied Products, 888/700-5527. Circle No. 264.

Die cutter: Martin, +33 (0) 4 72 14 74 74. Circle No. 265.

Stacker: Geo. M. Martin Co., 510/652-2200. Circle No. 266.

Die cutter, folder/gluer: The Bobst Group, 973/226-8000. Circle No. 267.

About the Author(s)

You May Also Like